6-27

Chapter 6 INSPECTION AND REPAIR OF BASIC ENGINE

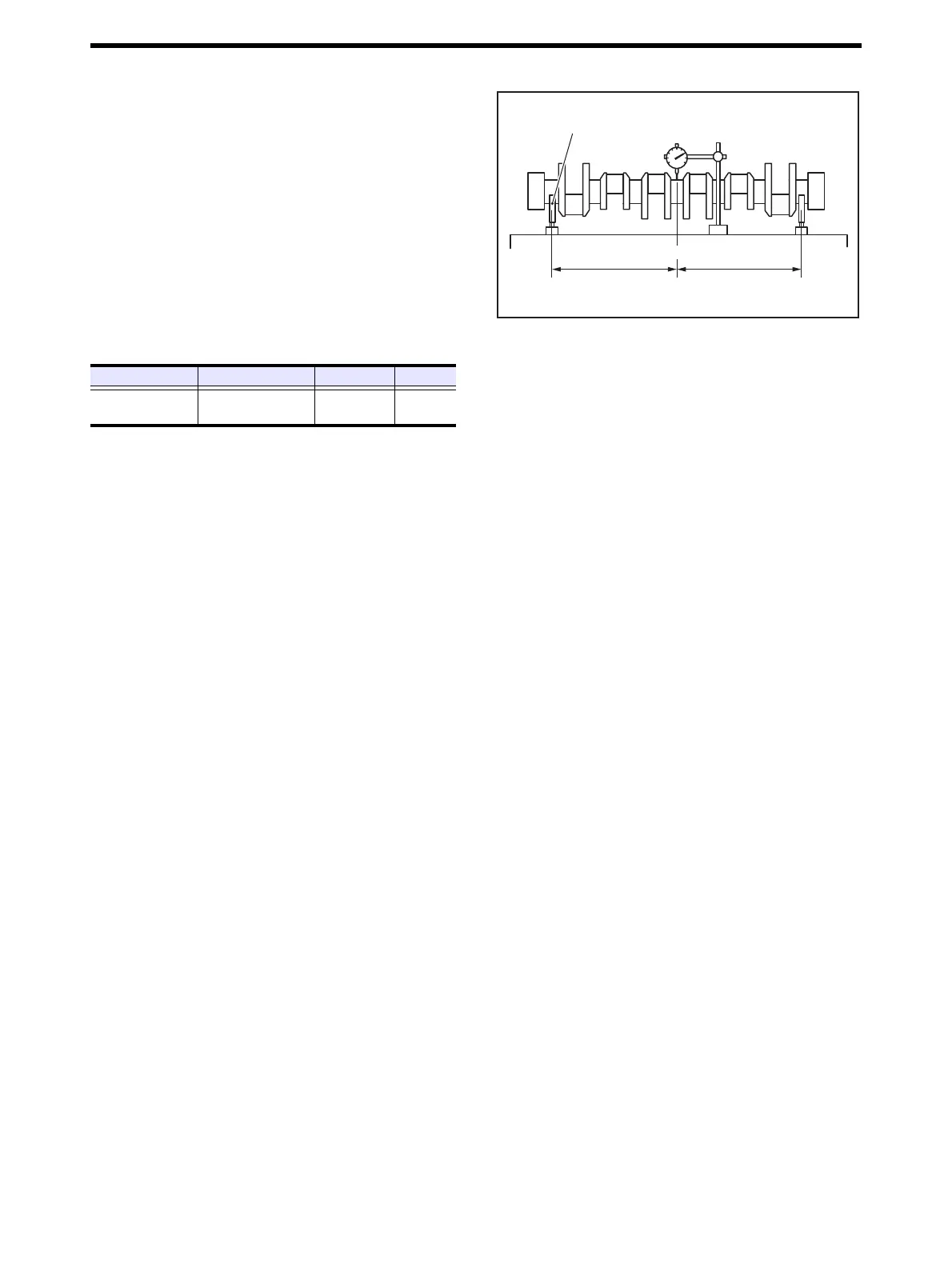

5.7 Crankshaft Runout - Measure

Support the crankshaft at front and rear main journals with

V-blocks, and measure the crankshaft runout at the center

main journal with dial gauge.If the runout deviates slightly

from the standard, correct the crankshaft by grinding.If the

value exceeds the standard considerably, straighten the

crankshaft with pressing machine.

If the value exceeds the limit, replace the crankshaft with a

new one.

If the crankshaft is repaired by grinding or pressing, inspect

the crankshaft for cracks and other harmful damage with

magnetic particle inspection.

Crankshaft Runout - Measure

Item Standard value Limit value Remarks

Crankshaft runout

0.04 mm

[0.0016 in.] or less

0.10 mm

[0.0039 in.]

TIR

V-block

Surface plate

1/2

1/2

Loading...

Loading...