7-24

Chapter 7 ASSEMBLY OF BASIC ENGINE

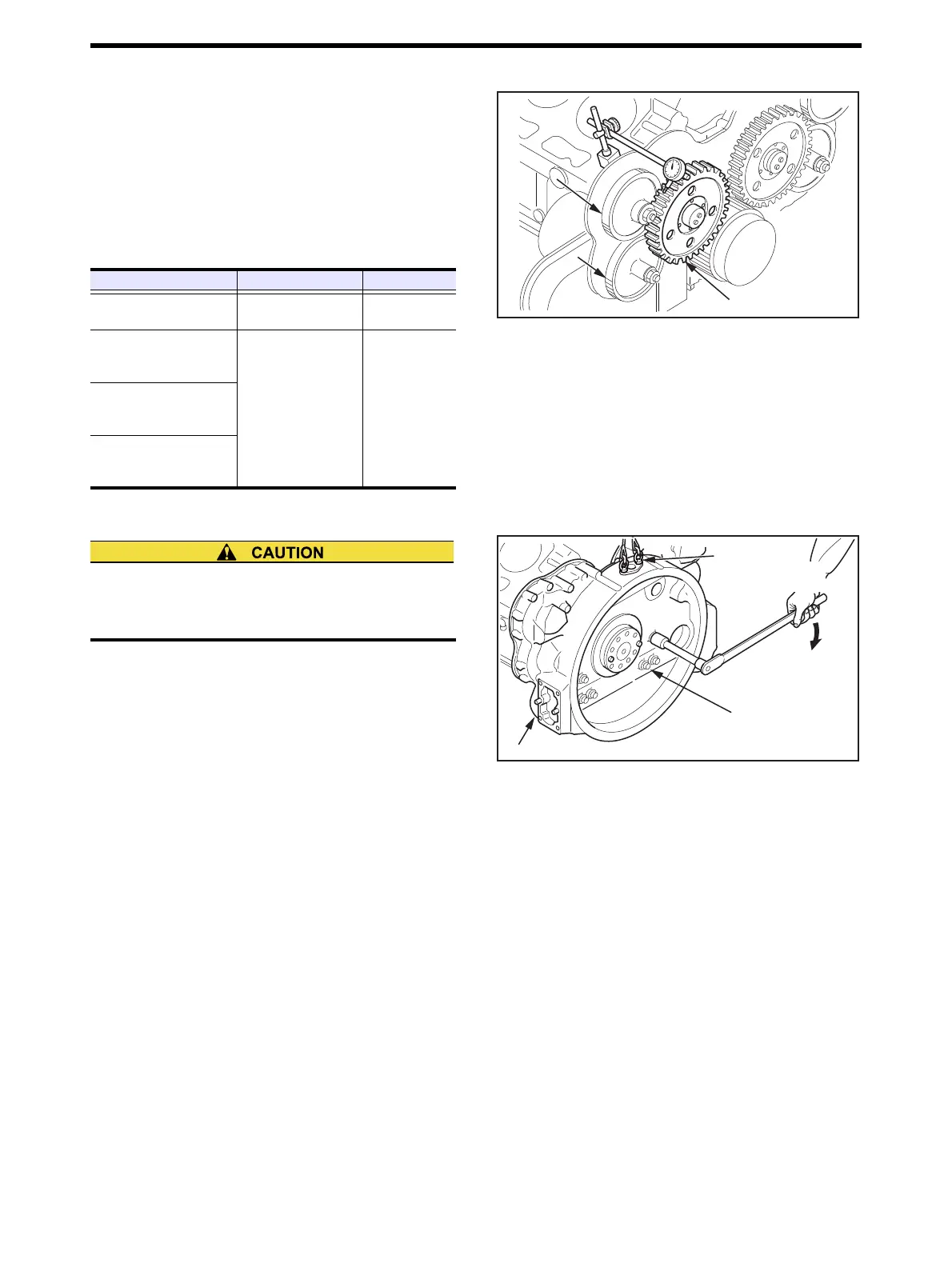

4.10 Timing Gear Backlash - Measure

Measure the backlash of timing gears using either method:

measure the gear backlash with a dial gauge applying its

probe to a tooth flank on the pitch circle at a right angle to

the tooth axis, or measure the clearance between gears by

inserting thickness gauges between the engaging gear

teeth.If the value exceeds the limit, replace the gears with

new ones.

Timing Gear Backlash - Measure

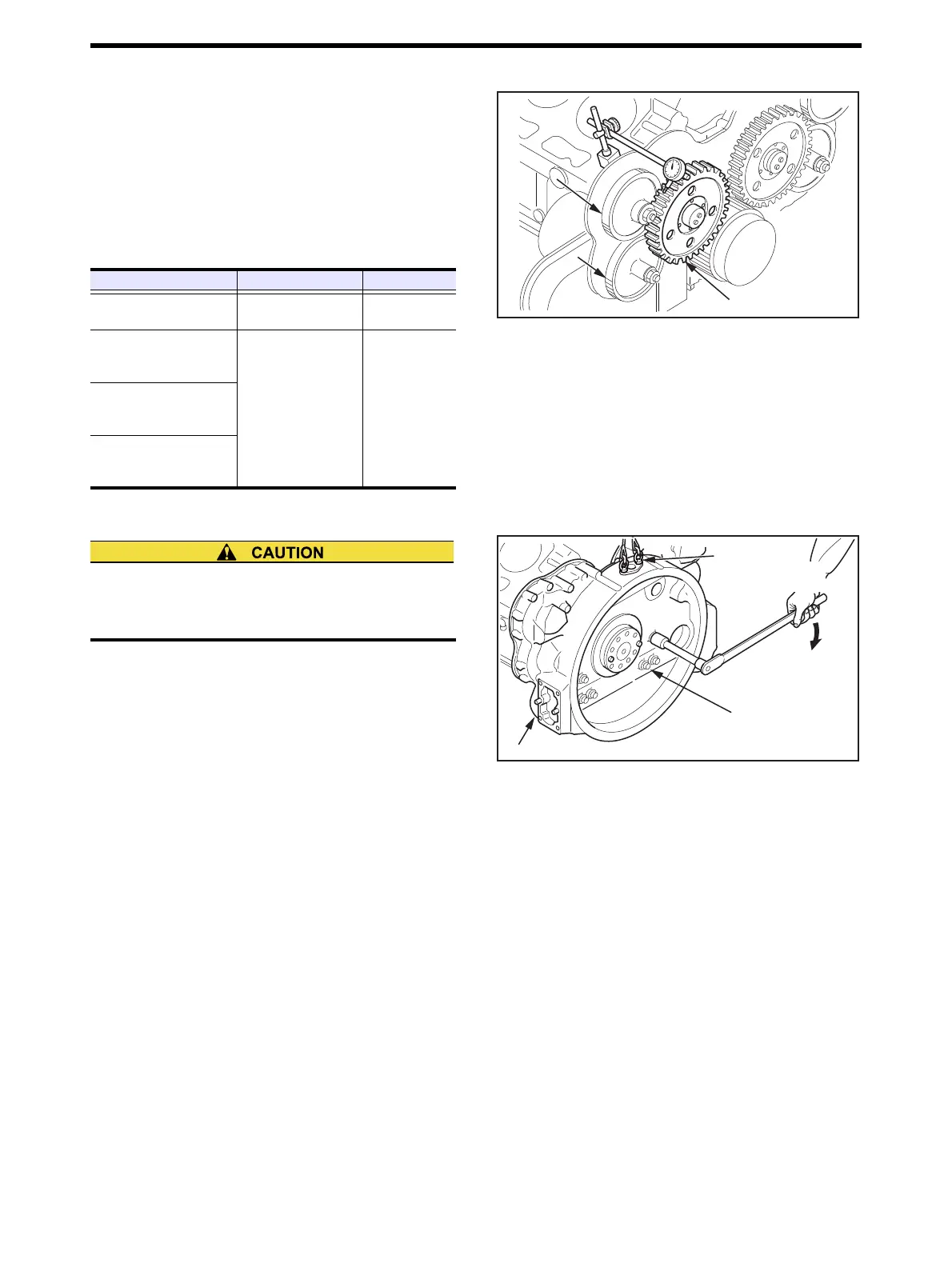

4.11 Timing Gear Case - Install

(1) Apply sealant (ThreeBond 1211) to the rare plate pack-

ing mating surface, and install the packing.

(2) Apply sealant (ThreeBond 1211) to the packing mating

surface to timing gear case.

(3) Set the eye bolt to timing gear case, align it with the

dowel pins, and install the timing gear case.

(4) Tighten the bolts to the specified torque.

(5) Cut off excessive packing carefully from the bottom of

crankcase.

Timing Gear Case - Install

Item Standard value Limit value

Backlash between crank

gear and idler gear

0.11 to 0.25 mm

[0.0043 to 0.0098 in.]

0.50 mm

[0.0197 in.]

Backlash between fuel

injection pump gear and

camshaft gear

0.12 to 0.18 mm

[0.0047 to 0.0071 in.]

0.50 mm

[0.0197 in.]

Backlash between idler

gear and fuel injection

pump gear

Backlash between crank-

shaft gear and oil pump

gear

Camshaft gear

Fuel injection

pump gear

Idler gear

Camshaft gear

Fuel injection

pump gear

Be careful not to drop or bump the timing gear case.It

will result in personnel injury as well as damage of the

timing gear case.

Timing gear case

M12:

98

±

4.9 N

{10

±

0.5 kgf

m}

[72.3

3.61 lbf

tt]

M16:

255

±

12.8 N

{26

±

1.3 kgf

m}

[188.1

9.44 lbf

ft]

Eyebolt

P/N:05930-00200

(M12 × 1.25 mm)

M12:

98 ± 4.9 N·m

{10 ± 0.5 kgf·m}

[72.3 ± 3.61 lbf·tt]

M16:

255 ± 12.8 N·m

{26 ± 1.3 kgf·m}

[188.1 ± 9.44 lbf·ft]

Loading...

Loading...