7-14

Chapter 7 ASSEMBLY OF BASIC ENGINE

2.11 Piston - Install

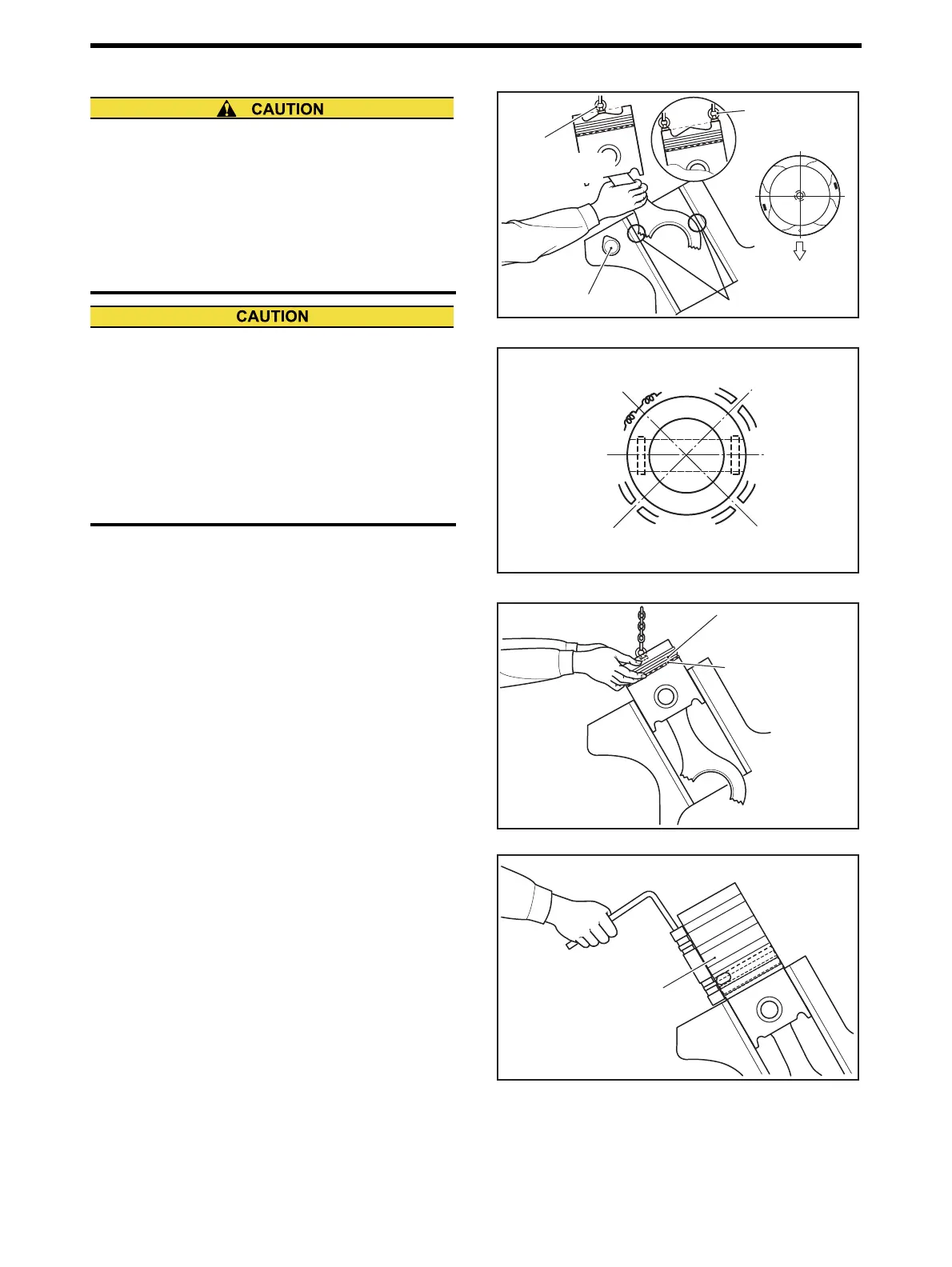

(1) Insert the connecting rod into the cylinder liner care-

fully not to damage the liner, and slowly lower the pis-

ton to the upper surface of crankcase.

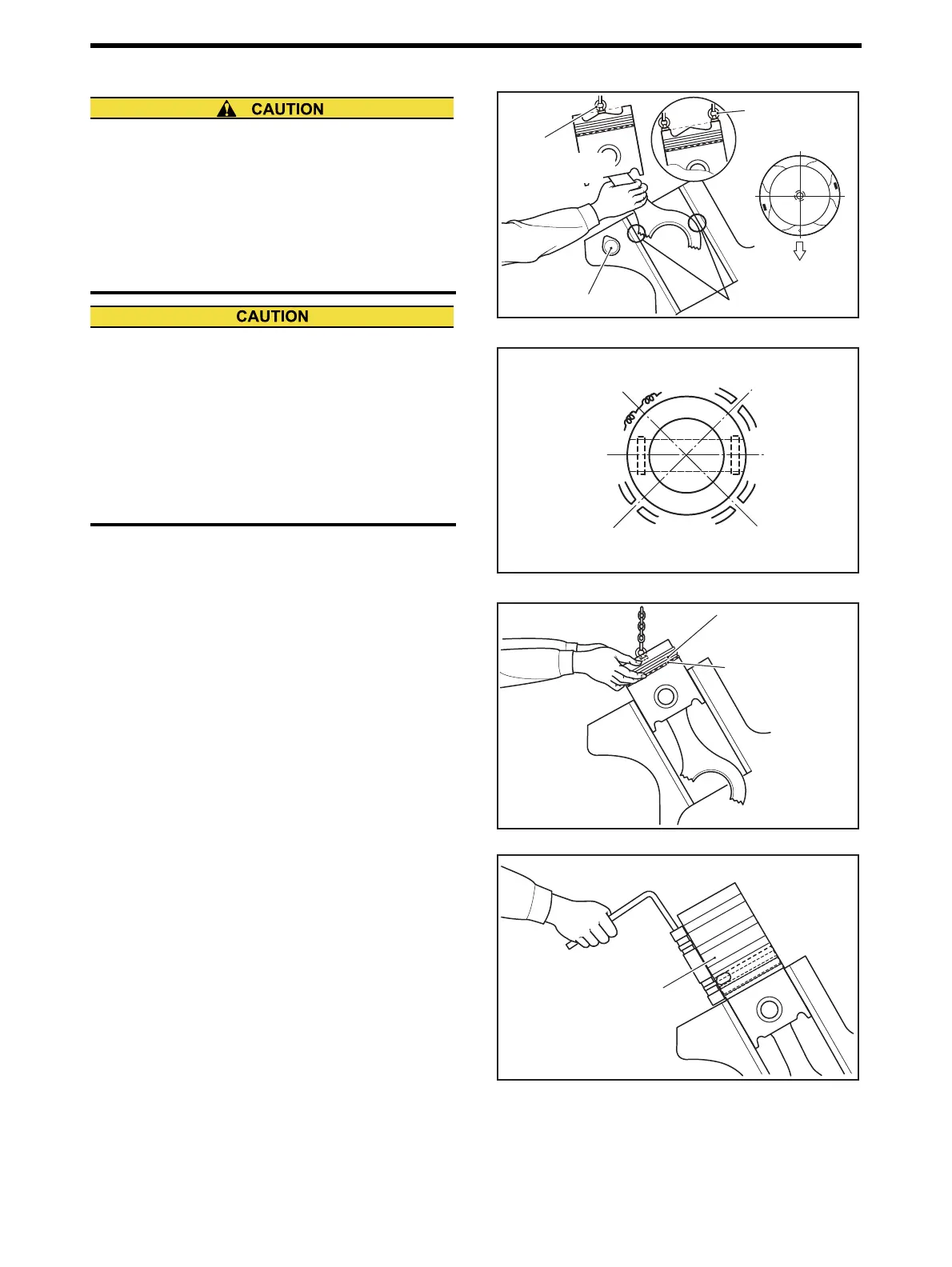

(2) Apply engine oil to the piston rings.

Place the end gaps equally spaced each other, avoiding

piston pin and thrust/anti-thrust directions.

(3) Hold the compression ring position of piston with

hands, and slowly insert the piston skirt into cylinder

liner.

Piston and Connecting Rod - Install

Piston Ring End Gaps - Place

Piston Skirt - Insert

(4) Verify again the positions of piston ring gaps.

Apply engine oil to the piston rings.

Apply engine oil to the inner surface of piston installer.

Verify the oil ring placed in the groove. Then, compress

the piston rings with piston installer.

Note: For piston ring placing, see above (2).

Piston Ring - Compress

When installing the piston, install the eye bolt to the

threaded hole on the piston top, and lift the piston with

chain block.When the installation work is done by

hand, be sure to take preventive measures so that pis-

ton does not falling down, and be very careful not to

hurt your hands and fingers or not to damage the

parts.

(a) Make sure that the "F" mark on top of the piston

faces the front of the engine.

(b) Checking through the inspection window on the

side of crankcase, make sure that the connecting

rod does not hit the piston cooling nozzle when

installing piston.

(c) To prevent the oil ring from impact damaging,

slowly insert the piston.

(

Camshaft

Be careful not to bump.

Eyebolt

P/N:45815-32201

(M8 × 1.25 mm)

Eyebolt

P/N:45815-32301

(M10 × 1.5 mm)

Engine front

“F” mark

No. 1 compression ring joint

Oil ring joint

Coil spring joint

No. 2 compression ring joint

Piston pin

Compression ring

Oil ring

Piston installer

P/N:37191-07100

Loading...

Loading...