7-25

Chapter 7 ASSEMBLY OF BASIC ENGINE

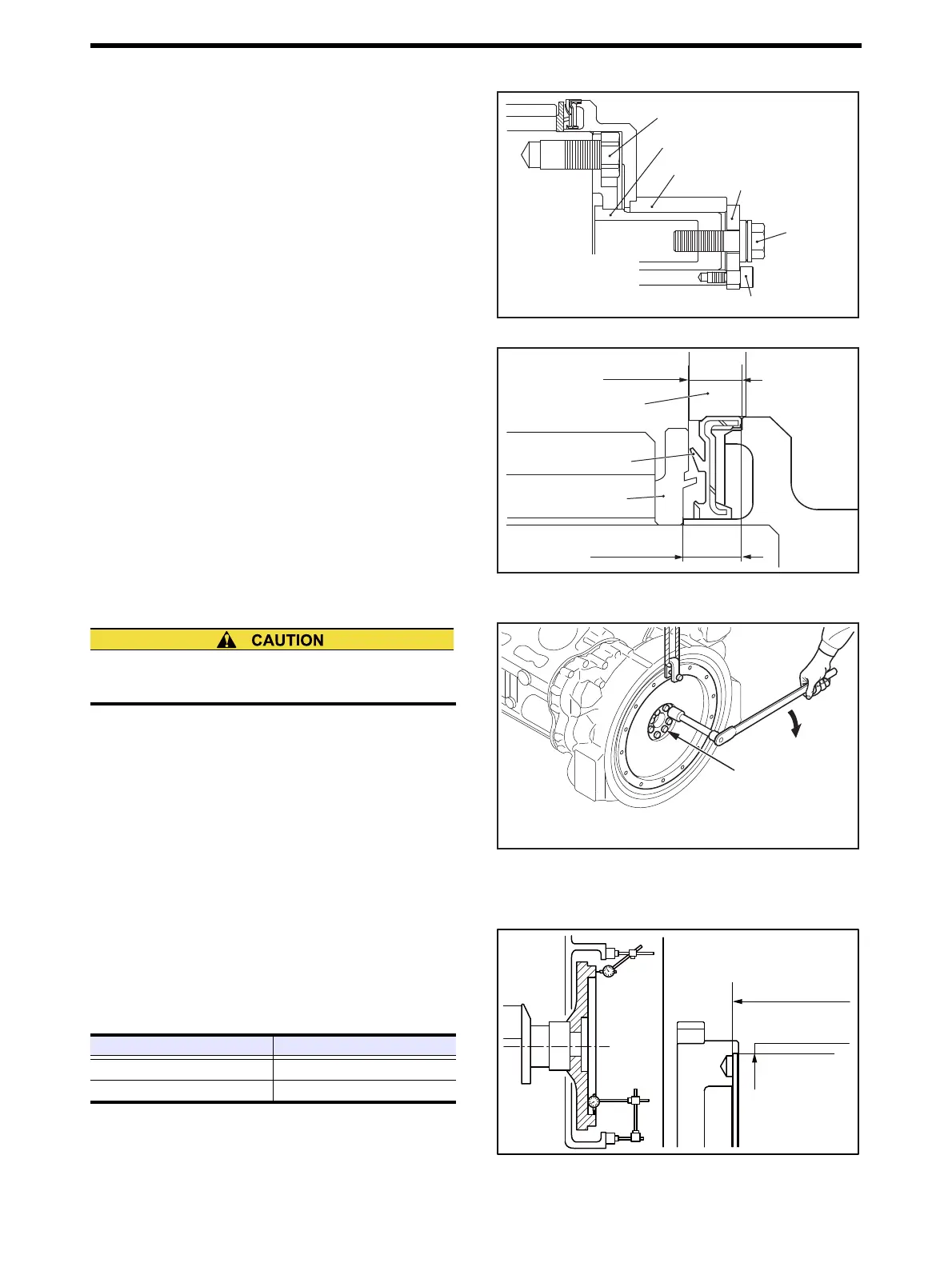

4.12 Rear Oil Seal - Install

Use the rear seal installer assembly to install the rear oil

seal.

(1) Apply clean engine oil evenly to the oil seal lip.

Note: Pay attention to the installing side of oil seal, and be

careful not to damage the oil seal.

(2) Install the guide flange to the crankshaft rear end face,

and fix it with insert bolts.

(3) Set the oil seal to insert and install it to the guide flange.

(4) Tighten the bolt on the guide flange to insert the oil seal

into timing gear case.

(5) Remove the installer assembly.

Rear Oil Seal - Install (1)

Rear Oil Seal - Install (2)

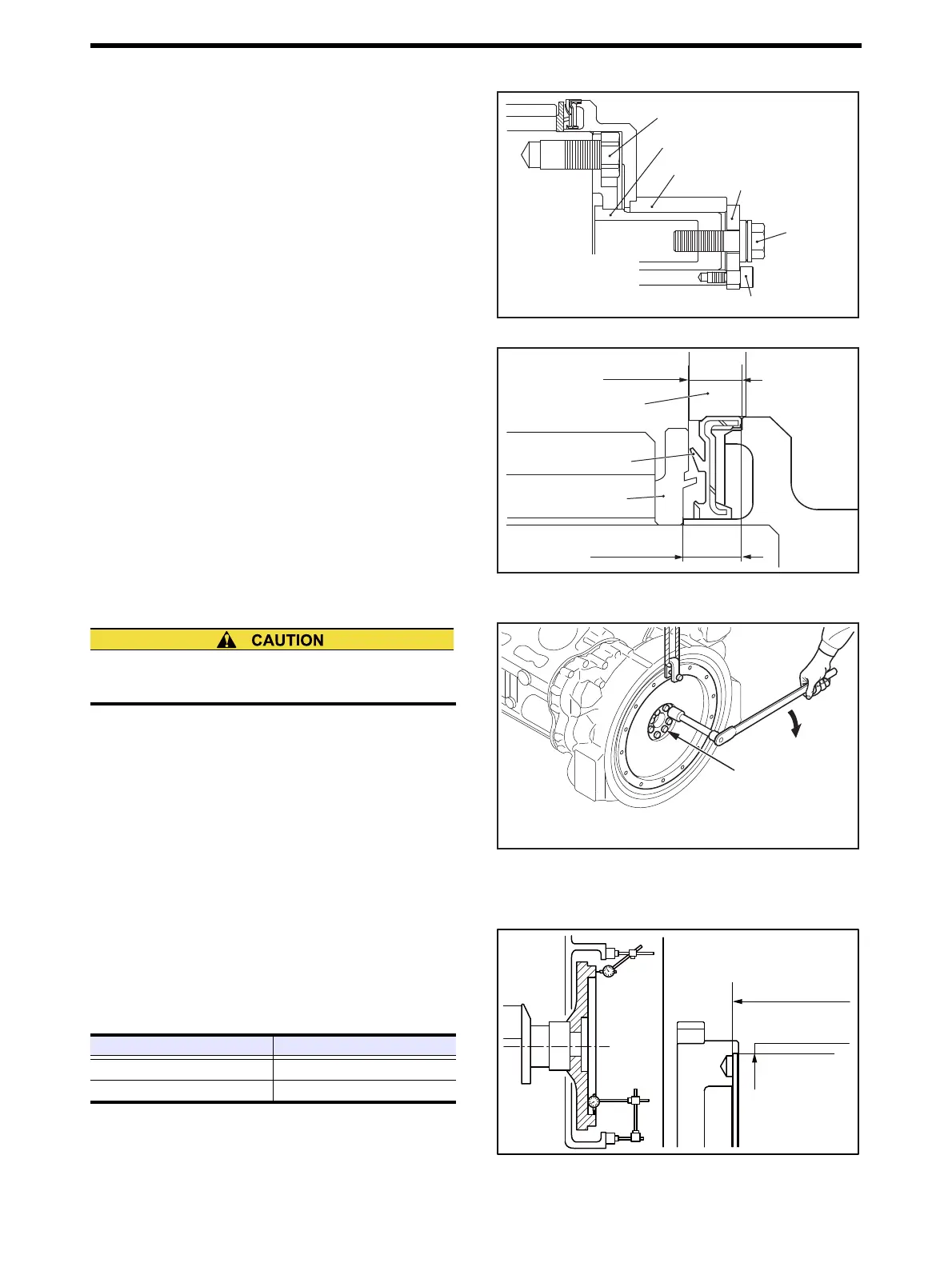

4.13 Flywheel - Install

(1) Check the mounting surfaces of flywheel and crank-

shaft to make sure that they are free from any foreign

material or damage.

(2) Hitch a sling to the flywheel.

(3) Install the flywheel by aligning its hole with dowel pin

on crankshaft.

(4) Apply engine oil to the bolt threads and bolt seat sur-

faces, then tighten the bolts to the specified torque.

Flywheel - Install

4.14 Flywheel Face and Radial Runout - Measure

Measure the face and radial runouts of the flywheel.

If the measured value extremely deviates from the standard,

check the assembling condition such as loose bolt or foreign

material collection on mounting faces.

Flywheel Face and Radial Runout - Measure

Rear seal installer

assembly

P/N:32591-07012

Insert bolt

Swing washer

Bolt

Insert

Guide flange

Socket bolt

12.5 mm

[0.492 in.]

Timing gear case

Oil seal

Slinger

3.5 ± 0.1 mm

[0.138 ± 0.004 in.]

Be careful not to drop or bump the flywheel.It will result

in personnel injury as well as damage of the flywheel.

539 ± 27 N·m

{55 ± 2.8 kgf·m}

[397.5 ± 19.9 lbf·ft]

[Wet]

Item Standard value

Face runout (reference) 0.285 mm [0.0112 in.] or less

Radial runout (reference) 0.127 mm [0.0050] or less

Face runout

measuring plane

Radial runout

measuring plane

Loading...

Loading...