System Hardware Features

26 0112-0109 H

Pipettor operations are controlled from within ScreenWorks Software

protocols, or some operations, for example, loading tips, can be

performed individually, directly through commands in the Instrument

menu. Connectors on the back of the pipettor head identify the head

format as 1536, 384, or 96 tips, so ScreenWorks Software only offers

valid plate formats and pipetting parameters for protocol setup.

The standard pipettor head uses air displacement to control aspiration

and dispense speed and volume. The volume of compound to be

transferred is configured in the software, and it is possible to draw

compound from multiple source plates to dispense into one destination

plate, or to aspirate from one plate and dispense to multiple well plates

or quadrants.

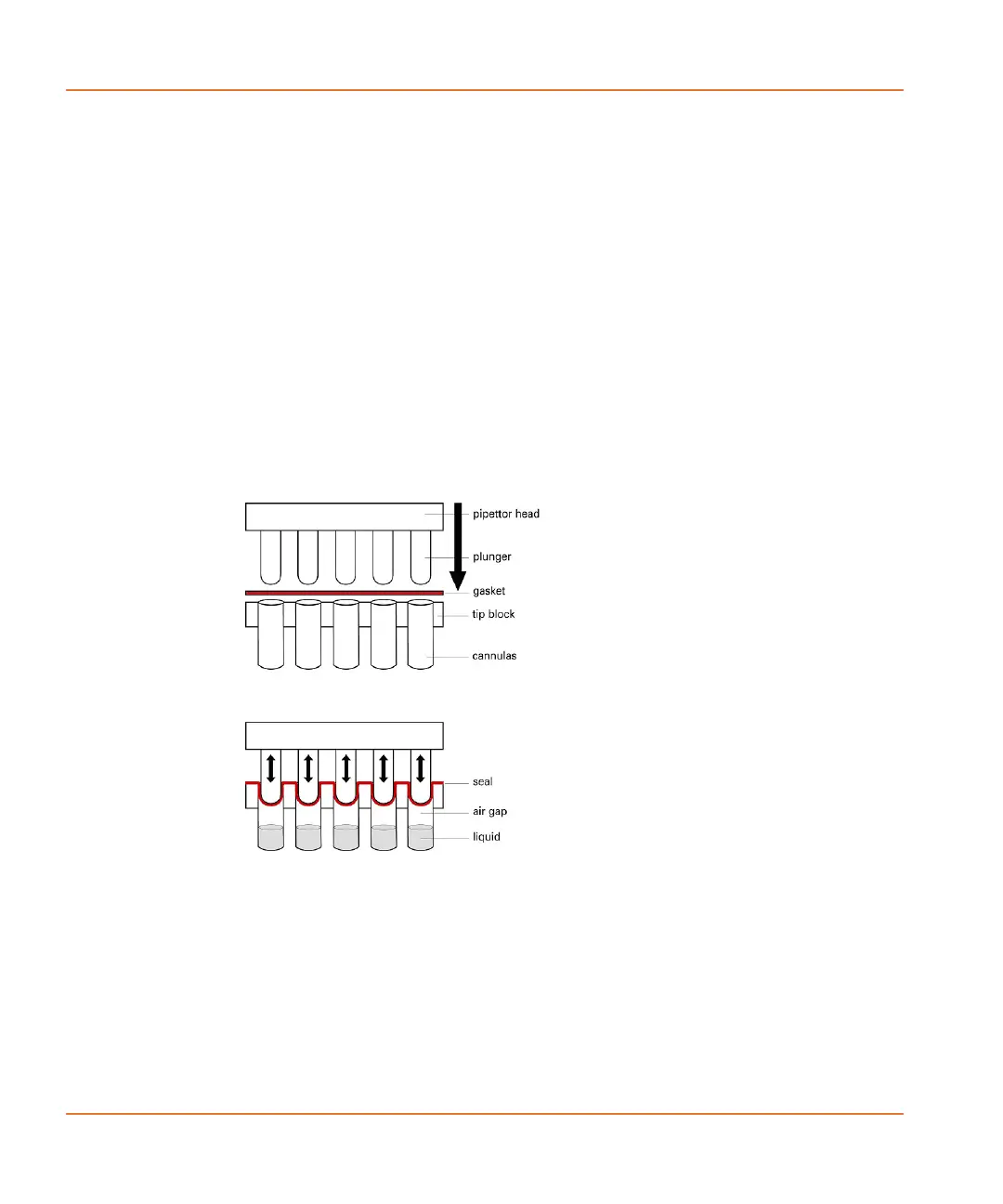

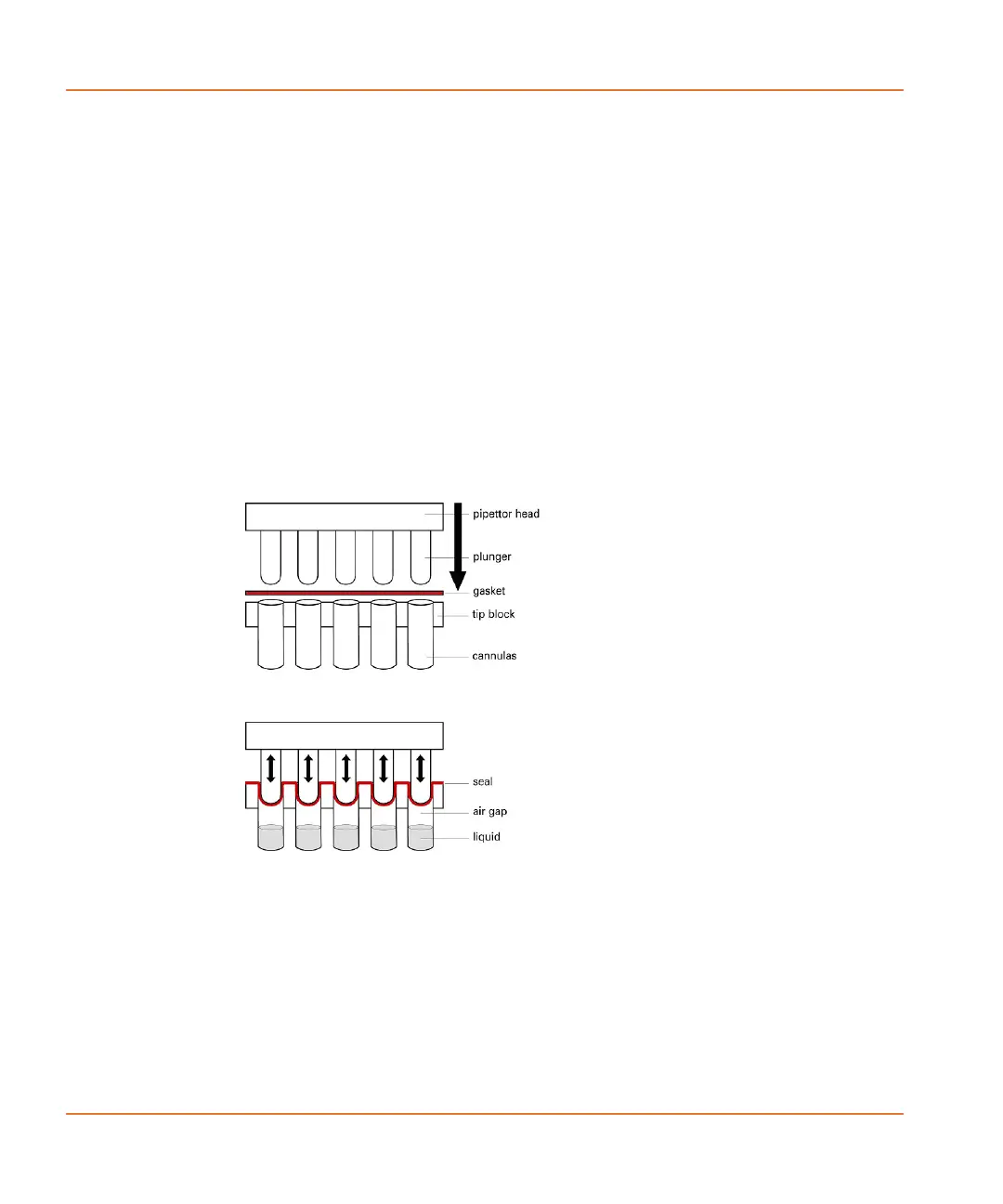

The 96- and 384-pipettor heads displace air in the disposable pipette

tips. In the 1536-pipettor head a plunger for each of the 1536 tips

presses against an elastic gasket seated on the tip block. When the

plungers move down they create an initial seal between the gasket and

tip block. Once the seal is created, further plunger movement causes

air displacement in the tip block (see Figure 2-4).

Figure 2-4 Seal creation in the 1536-pipettor head.

Minimum pipettor precision is as follows:

• 3% for 75 μL additions (96-well).

• 4% for 25 μL additions (384-well)

• 6% for 3 μL additions (1536-well)

Performance is dependent on tip/gasket seating and can be

compromised if the seal is broken. Use only Molecular Devices

recommended tips and gaskets to ensure the highest accuracy and to

reduce the possibility of damaging the pipettor. See Appendix C:

Loading...

Loading...