SECTION 5

DISASSEMBLY AND ASSEMBLY

103

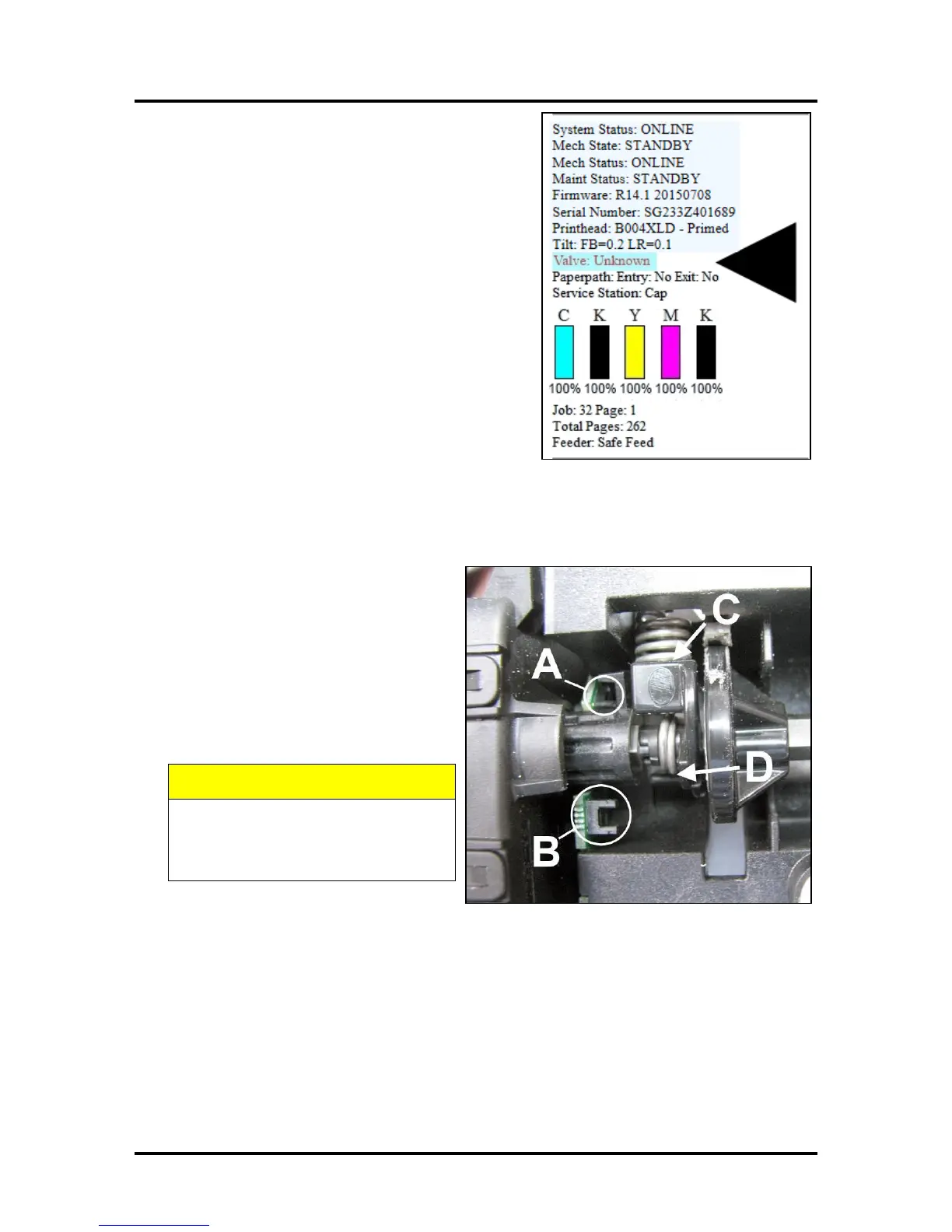

Cleaning Dual Pinch Valve Sensors

If “Valve: Unknown” appears for other than a few seconds

in the “Valve:” line of the Printer Toolbox, it may indicate

that the DPV Sensors are blocked (dusty/dirty).

The Print Engine must be removed and turned on its side for

this procedure. See “Removing the Print Engine” on

previous pages.

CAUTION! Please be sure the Waste Ink Tray and Service

Station are removed from the Print Engine, before turning the

print engine on its side. This will help reduce the chance that

waste ink will run out of these items and into areas it should

not be; causing damage and creating allot of cleanup time.

Try to finish this procedure as quickly as possible.

Once the print engine is upright again, re-install the Waste Ink

Tray as soon as possible.

1. Remove the Print Engine Base.

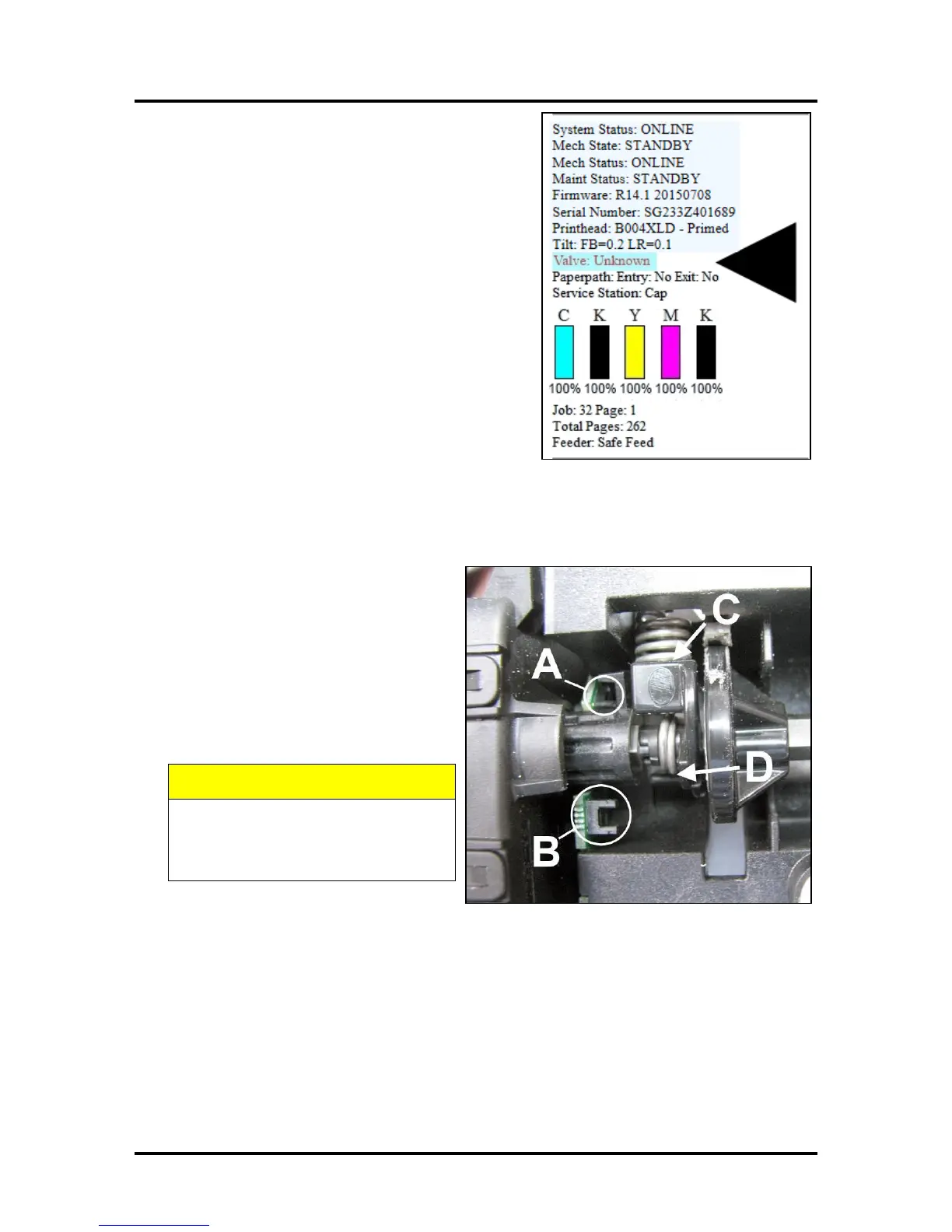

2. Locate the Dual Pinch Valve (DPV) Assembly.

3. Use canned air to blow the debris off the

two Sensors [A & B] located on the

DPV Sensor PC Board.

4. As a preventive measure, apply a small

amount of Super Lube 21030 grease (or

equivalent) to the space between the

springs and the DPV Adaptor [C & D].

(You will need a small brush or

toothpick to reach these small, tight

areas.)

DO NOT GET GREASE ON THE

SURROUNDING AREAS INCLUDING

THE DPV SENSOR PC BOARD,

SENSORS OR SENSOR FLAGS.

Loading...

Loading...