SECTION 6

MAINTENANCE

143

Section 6 – Service Maintenance

General, periodic maintenance is needed to keep the Printer in good working order. Many tasks can be

performed by operators with basic supplies, no special tools needed. Other tasks should only be performed

by trained service personnel.

Maintenance Supplies & Equipment: Flashlight, small telescoping mirror, hard-bristled toothbrush,

tweezers, small flathead screwdriver, powder-free nitrile gloves, protective clothing and eyewear, vacuum

with wand, deionized/distilled water, Super Lube 21030 synthetic grease (or equivalent), Loctite 38650

copper anti-seize (or equivalent), can of compressed air, foam or lint-free cotton swabs, lint-free wipes,

disposable shop towels.

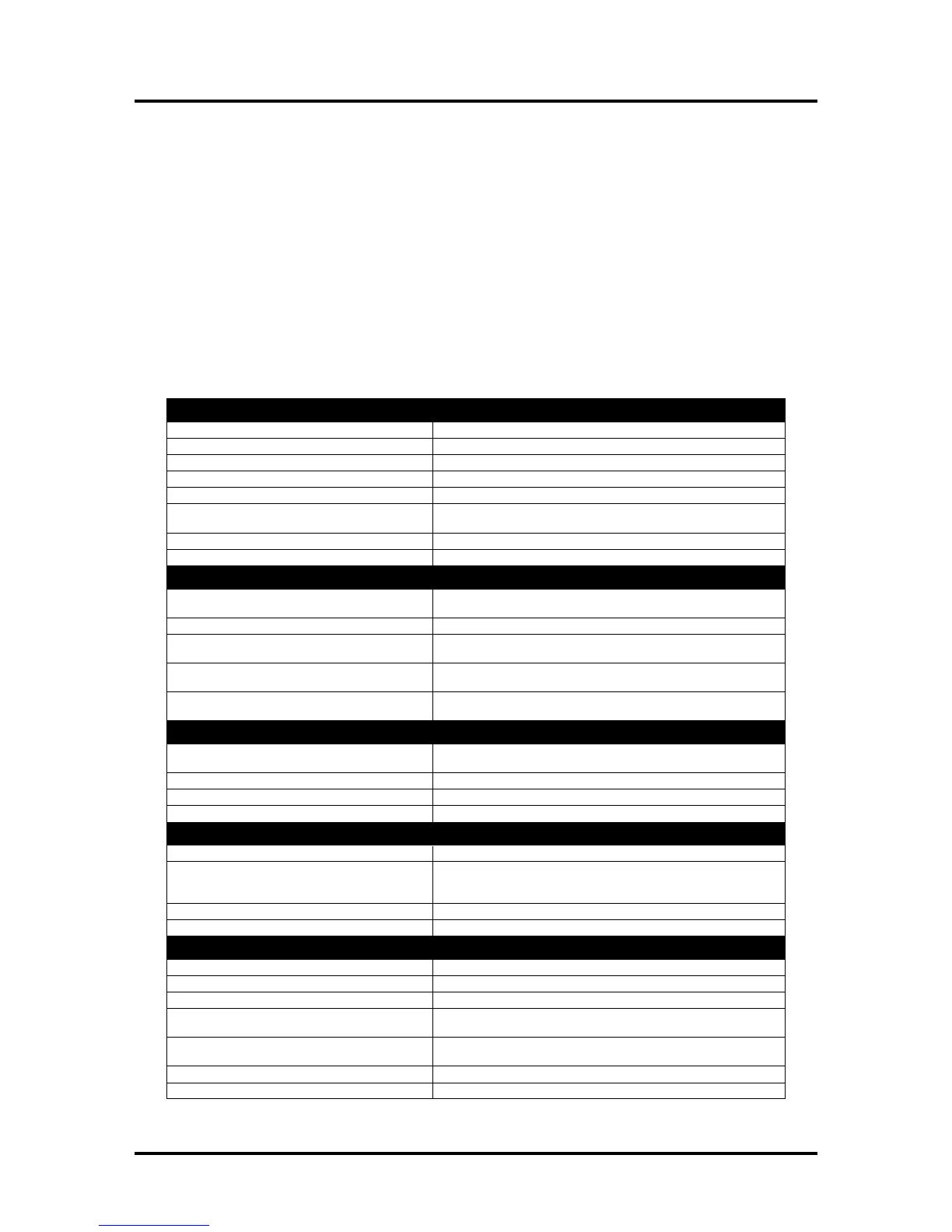

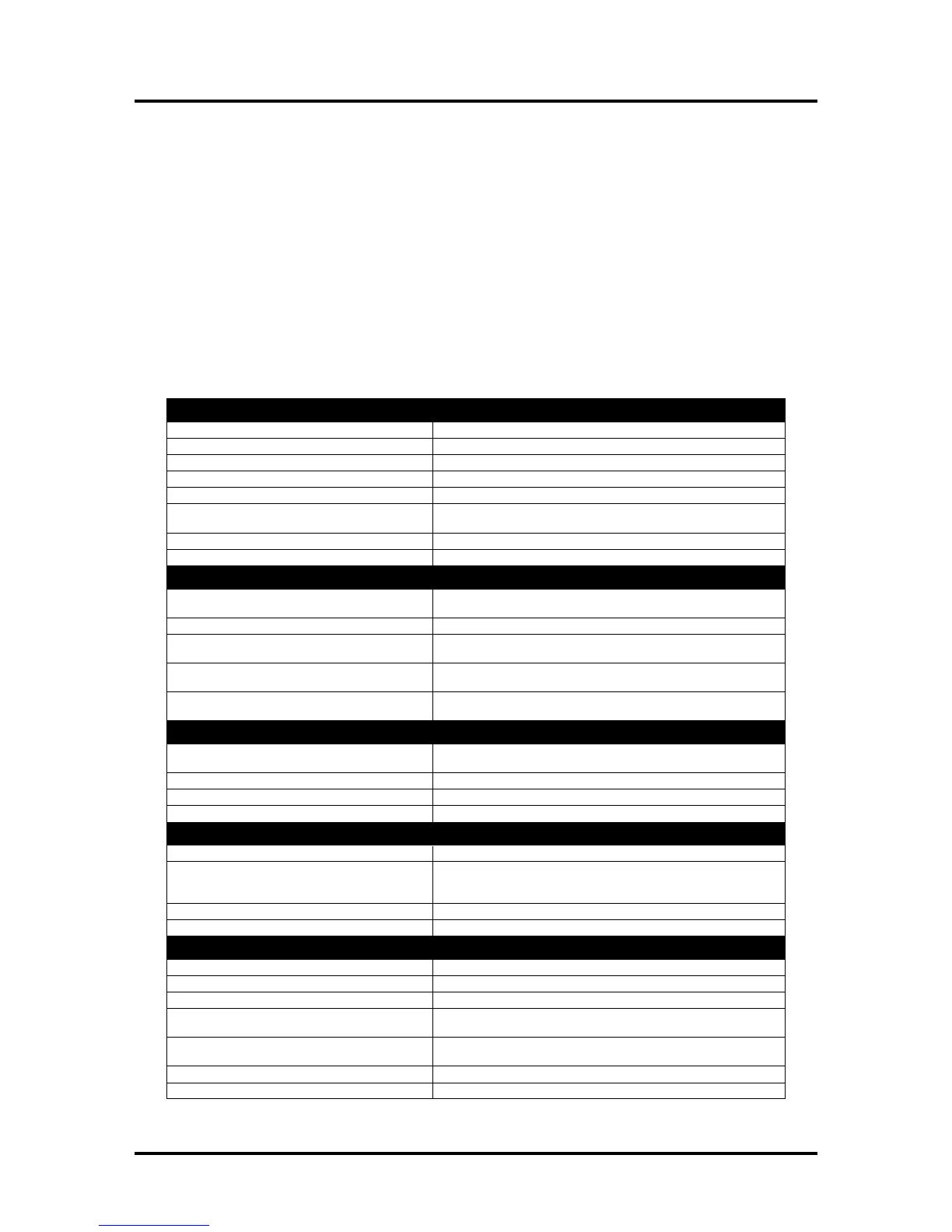

Maintenance Schedule

NOTE: High volume usage may require more frequent maintenance.

AS NEEDED MAINTENANCE (Depending on Printer usage)

Cleaning (Remove media fibers and ink residue):

Media path, Service Station (Wiper Roller, Platen)

Inspect and clean after every Printhead removal.

Wipe as needed to maintain print quality.

Replace with Printhead to help avoid possible damage to new head.

Clean contacts after every Printhead removal.

Lubrication (Super Lube 21030)

Service Station (cams, lifting arm pivot points and guide tracks), Lift

Motor Gear

Printhead, Head Media Guide, Lip of Cap

Wipe these areas clean after system is primed or as needed.

Wiper Roller, Ink Waste Tray, Ink Revolver Couplings, Tubing, Belts.

Clean manually prior to installing, after paper jams and when

automated servicing does not clear nozzles.

Clean to remove excess ink residue and debris.

Print Engine: System Components, Paper Path

surfaces (upper and lower.)

Clean to remove excess ink residue and debris.

NOTE: DO NOT wipe Starwheel Assemblies.

Clean after: Installing and priming, removing and replacing, priming

or repriming, contamination.

Service Station:

Capping Station and Platen

Empty/clean excess ink residue and debris.

Encoder Wheel (Z2i Print Engines with exposed

Encoder Wheels only.)

Clean spattered ink or residue.

Clean to remove excess ink residue and debris.

Clean to remove excess ink residue and debris.

Wiper Roller, Cap Station Seal

Inspect for proper operation and wear.

Inspect for proper operation and residue build-up.

Ink Tubing, Connections, Peristaltic Pump,

Pinch Valve & Vents, Buffer Boxes, Ink

Revolver Couplings

Inspect for leaks, kinks, pinches, proper operation.

Inspect for excessive ink saturation or leakage.

Inspect for proper operation, debris and wear.

Verify latest version and update if needed.

Clean to remove excess ink residue and debris.

Ink Tank Latches/Ink Tank Bay

Inspect for proper operation, wear, debris, leakage.

Inspect Moving Parts: Media Path, Pump, Pinch

Valves and Service Station

Verify smooth operation. Listen for unusual noise indicating damage

or wear.

Lubrication (Super Lube 21030)

Lifter Motor Gear, Service Station (cams, lifting arm pivot points,

wiper roller gears, guide tracks)

Lubrication (Loctite 38650)

Grit Roller Ground Clips, Springs and Washers

Service Station: Wiper Roller, Sled Assembly,

Clean to remove excess ink residue and debris.

Loading...

Loading...