SECTION 4

MEASUREMENTS & ADJUSTMENTS

49

Feeder Encoder Sensor and Encoder Wheel

The Feeder Encoder is responsible for matching the speed of the feed section with the speed of the

print engine. If a problem develops with this sensor (example: encoder wheel gets dirty), then you will

normally see issues with the transition of media from the feed section to the print engine.

Possible Symptom: Frequent paper jams at entrance side of

print engine.

Media crashing into the entrance side of print engine. Media

is being delivered too fast.

Media getting held back by the feed section. Feed section

seems to stop prematurely; with media partially fed into the

print engine.

The following messages may appear in the Toolbox utility.

PAPERPATH_PRINTZONE_BLOCKED

or

PAPERPATH_PAPERJAM

Cleaning: Clean the sensor using compressed air.

Clean the encoder wheel using a soft damp cloth.

If the encoder wheel becomes discolored or damaged it may need to be replaced.

If cleaning and adjustment does not cure issue, as a last effort before replacement, you can try to clean

the encoder sensor with a damp cloth or cotton swab.

Adjustment:

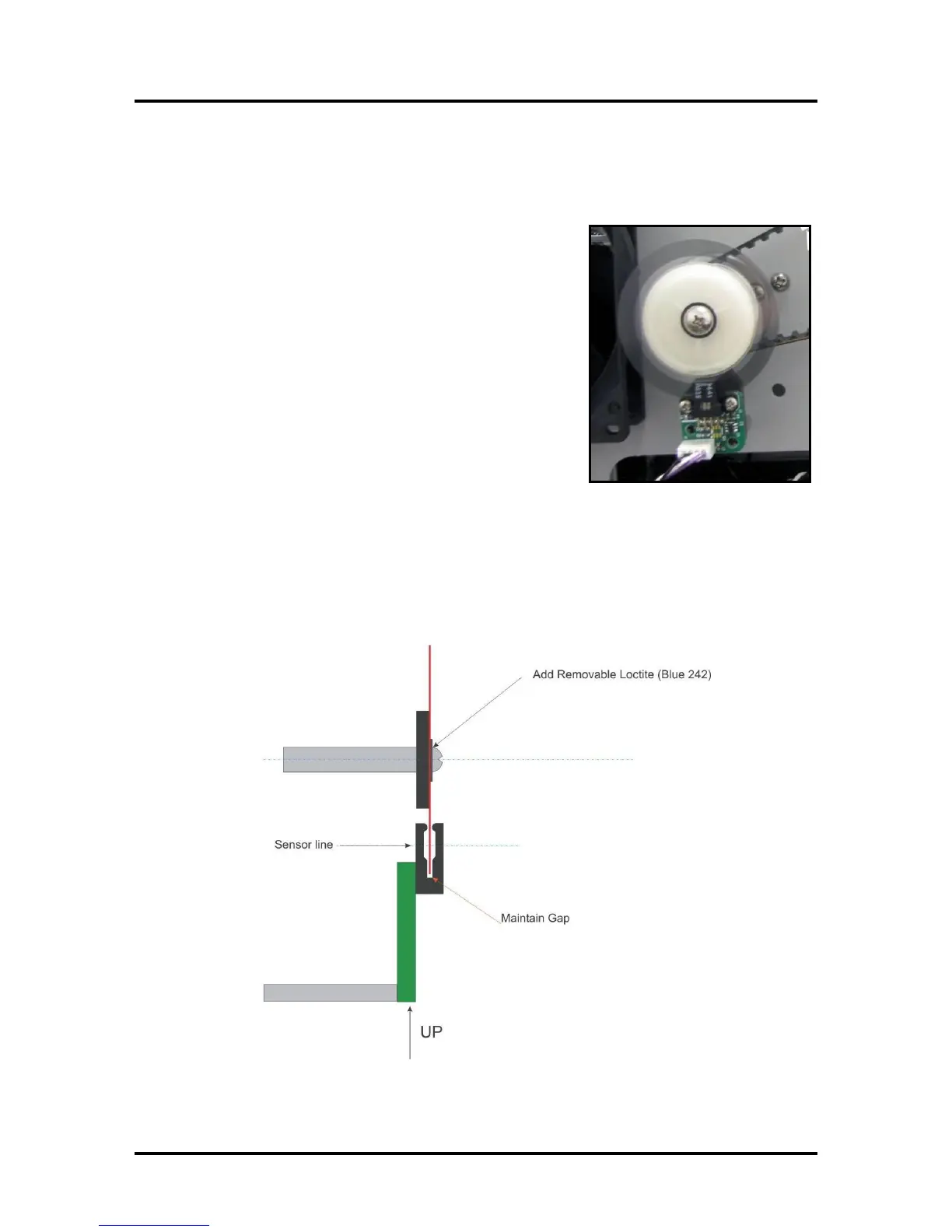

The position of the encoder can be adjusted by loosening the two screws that secure the sensor to the

mounting posts. Normally the encoder sensor is adjusted so it sits at the highest point. However if you

experience feeding issues; try adjusting it lower.

Feeder Encoder Sensor and Wheel (Side View)

Loading...

Loading...