SECTION 2

TROUBLESHOOTING

33

Jams in the Printer

When the printer detects a media feed problem, it will stop automatically.

Depending on where the media stops; the message “PAPERPATH_PAPERJAM” or

“PAPERPATH_FEED_TIMEOUT” will be displayed in the Toolbox.

Once the jam has been removed from the system and the print engine is closed; press the PAPER/RESUME

button on the control panel or press the Clear Error button in the Toolbox to continue printing.

TIP: If the printer will not “resume” after a “PAPERPATH_PAPERJAM” is detected (Toolbox System

Status changes to “ONLINE” and the Mech State changes to “PREP”, but it will not continue printing); this

is normally an indication that one or more of the media sensors is still interrupted. Please be sure to remove

media from and check/clean the Paperpath sensors and the Feed Sensor.

Some possible causes for jamming are:

1. Feeding more than one piece of media at a time (double-feeding), due to improper sheet separation

adjustment, improper media loading, or nested media (envelopes that are caught under the flap of

another envelope or stick to one another).

2. Damaged media, such as dog-eared (turned down corners), curled or bowed media.

3. Media that is not stiff enough may not be usable. Media that meets Postal stiffness requirements for

automated feeding is acceptable in the Digital Color Printer.

4. Media that is too thick for the printer.

5. Media that is too wide for the printer or media that skews as it travels through the printer.

Removing Jammed Media

Clearing a jam depends on where the jam occurred.

From the Feed Section: Remove media stack. Loosen and lift the sheet

separators to clear the jam. Then re-adjust the sheet separators as described in

this manual.

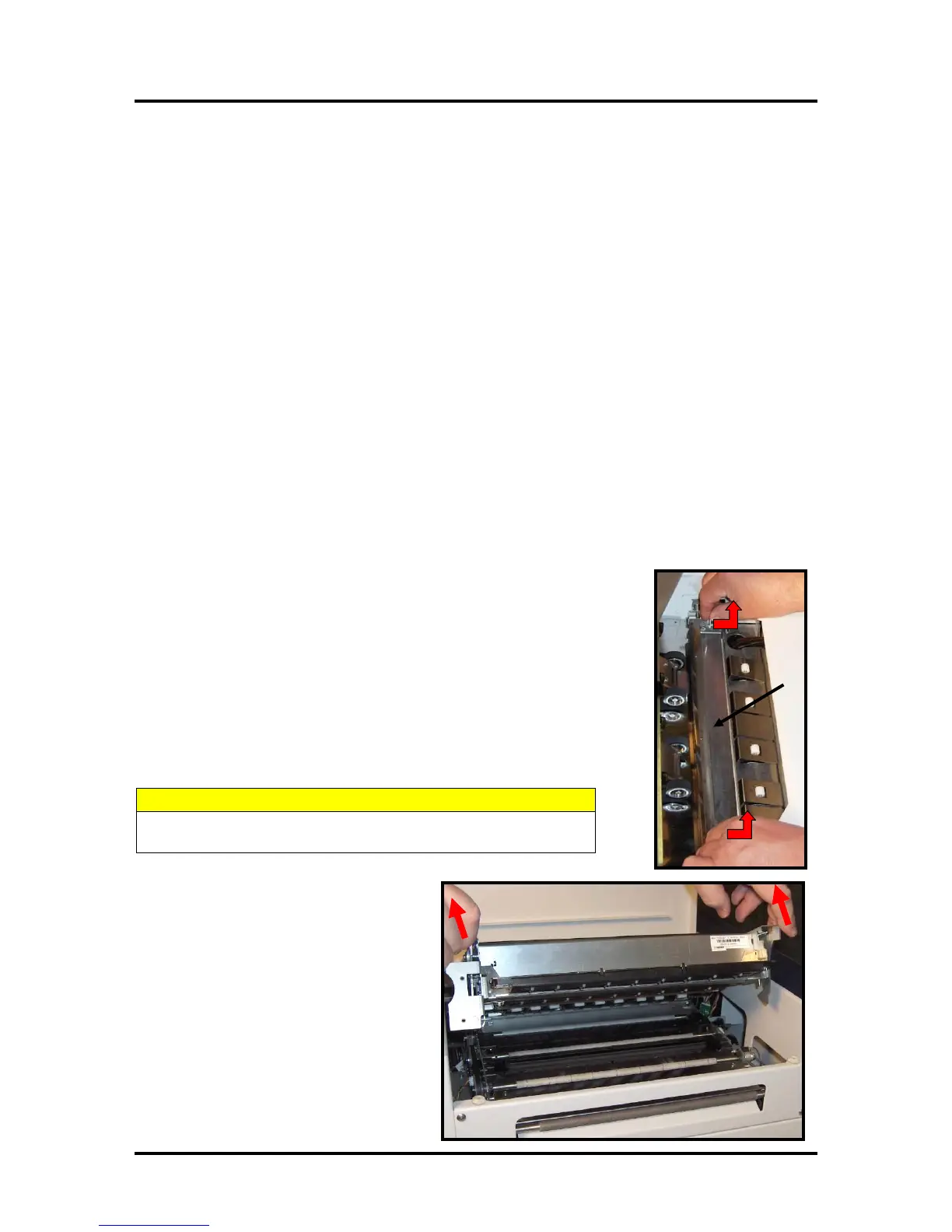

Under the Antistatic Brush Assembly: If necessary, remove the Antistatic

Brush Assembly [A] to access jammed material. Unlatch the two latches (one

on either side of the Assembly) and lift the assembly off the four mounting pins

as shown. Do not bend the guide fingers! Clear the jam, and then carefully

reinstall the Antistatic Brush Assembly. Make sure brush assembly is correctly

reinstalled and aligned before starting to print. Assembly should sit flat on

transport area surface

BE CAREFULL NOT TO PINCH OR CUT THE INK HOSES

WHEN RE-INSTALLING THE ANTISTATIC BRUSH ASSY.

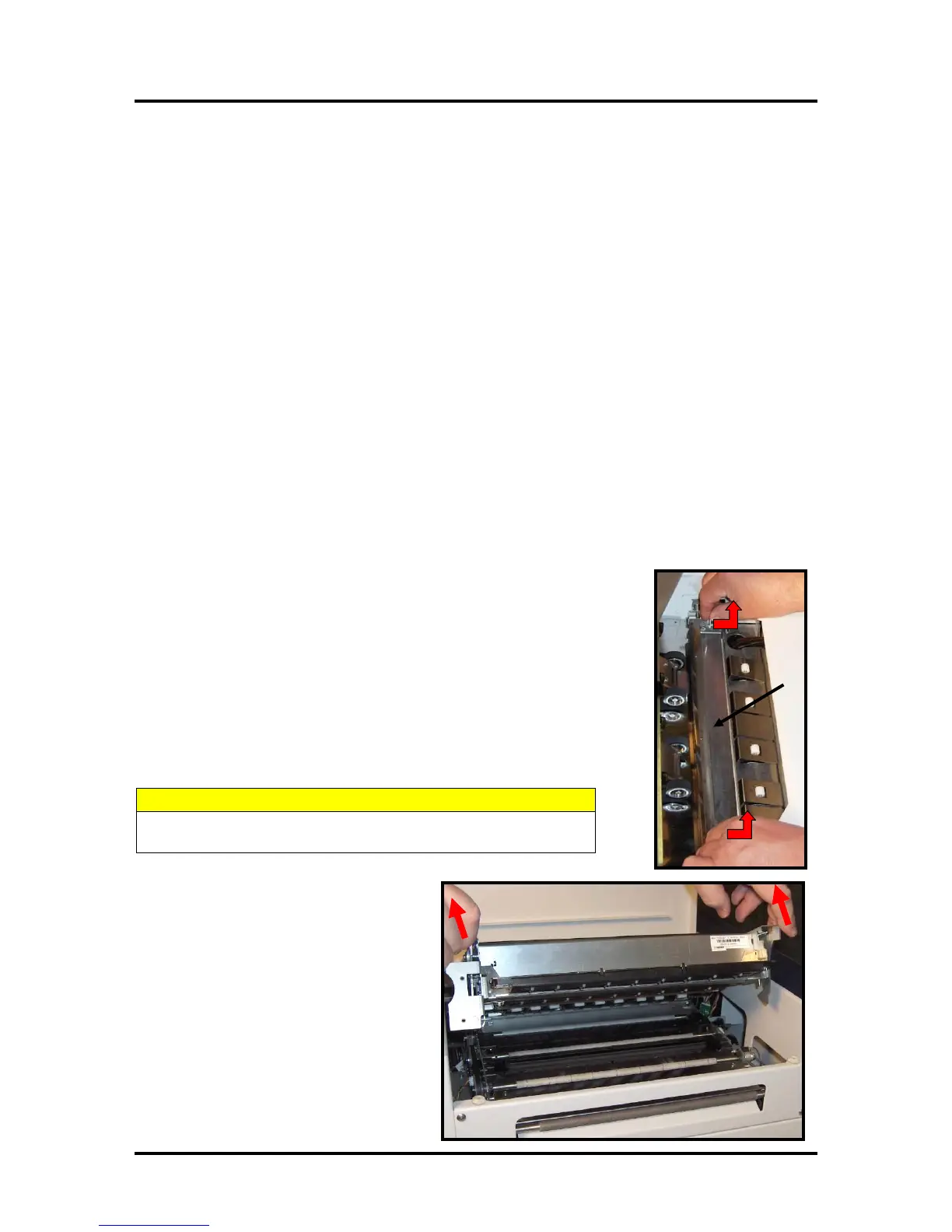

From the Print Engine Area: Open the Top

Cover. Lift up on the two latches (one on

each side of the print engine assembly) and

raise (swing open) the Print Engine

Assembly [C]. Clear the jam, then lower and

re-latch the Print Engine Assembly. Then

close the Top Cover.

CAUTION: Do NOT open the Print Engine

Assembly to an angle greater than 60º.

Damage to the ink color tubes and other

issues will result.

Loading...

Loading...