SECTION 2

TROUBLESHOOTING

17

The Printer

Troubleshooting Tip: If you recently replaced the Main Board and you are experiencing problems; please

see “Replacing the Main PC Board (MPCA)” and “MPCA (Main Printed Circuit Assembly) Connections”;

to verify your connections. Also check for damaged wires and loose connections.

NOTE: The printer will not print if any of the five ink tanks are empty or missing.

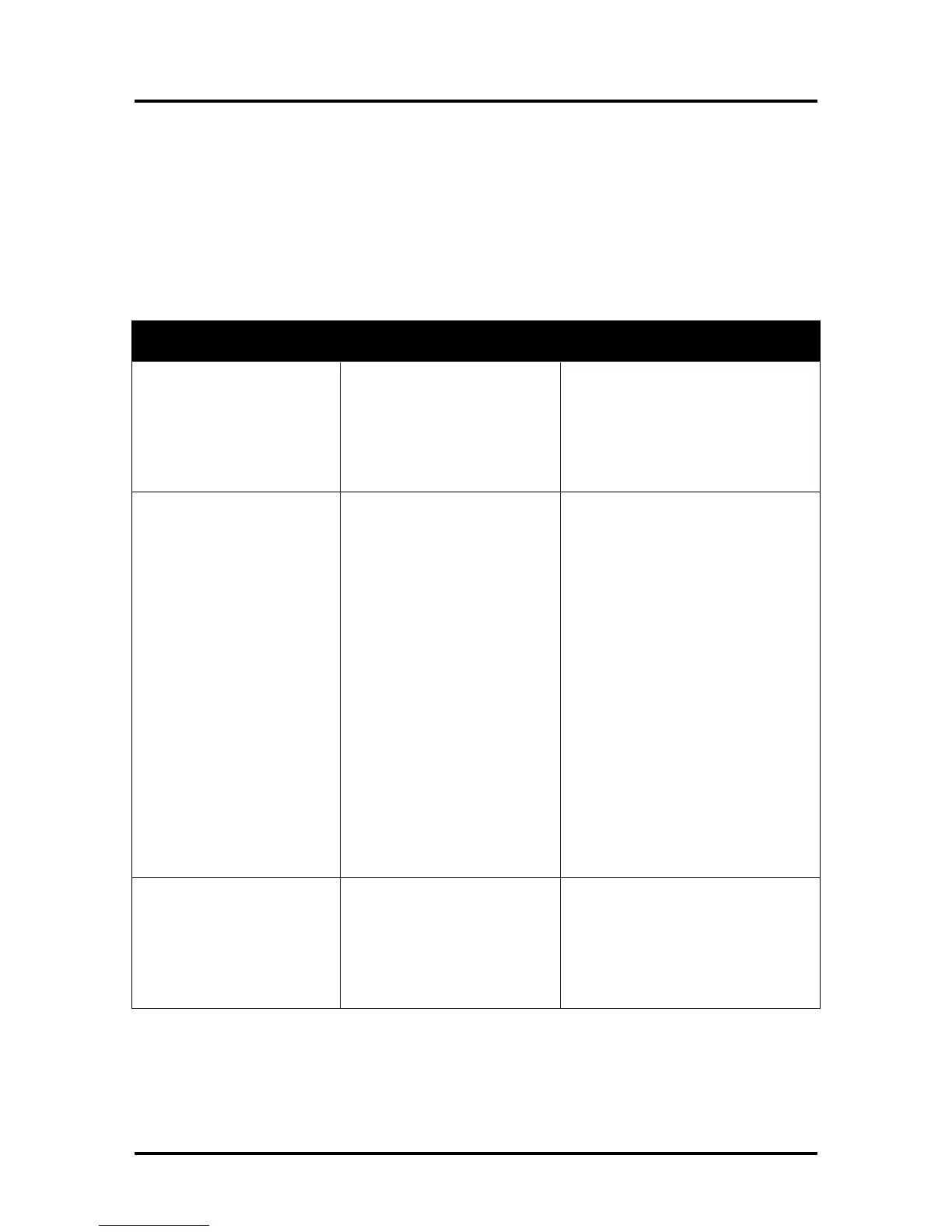

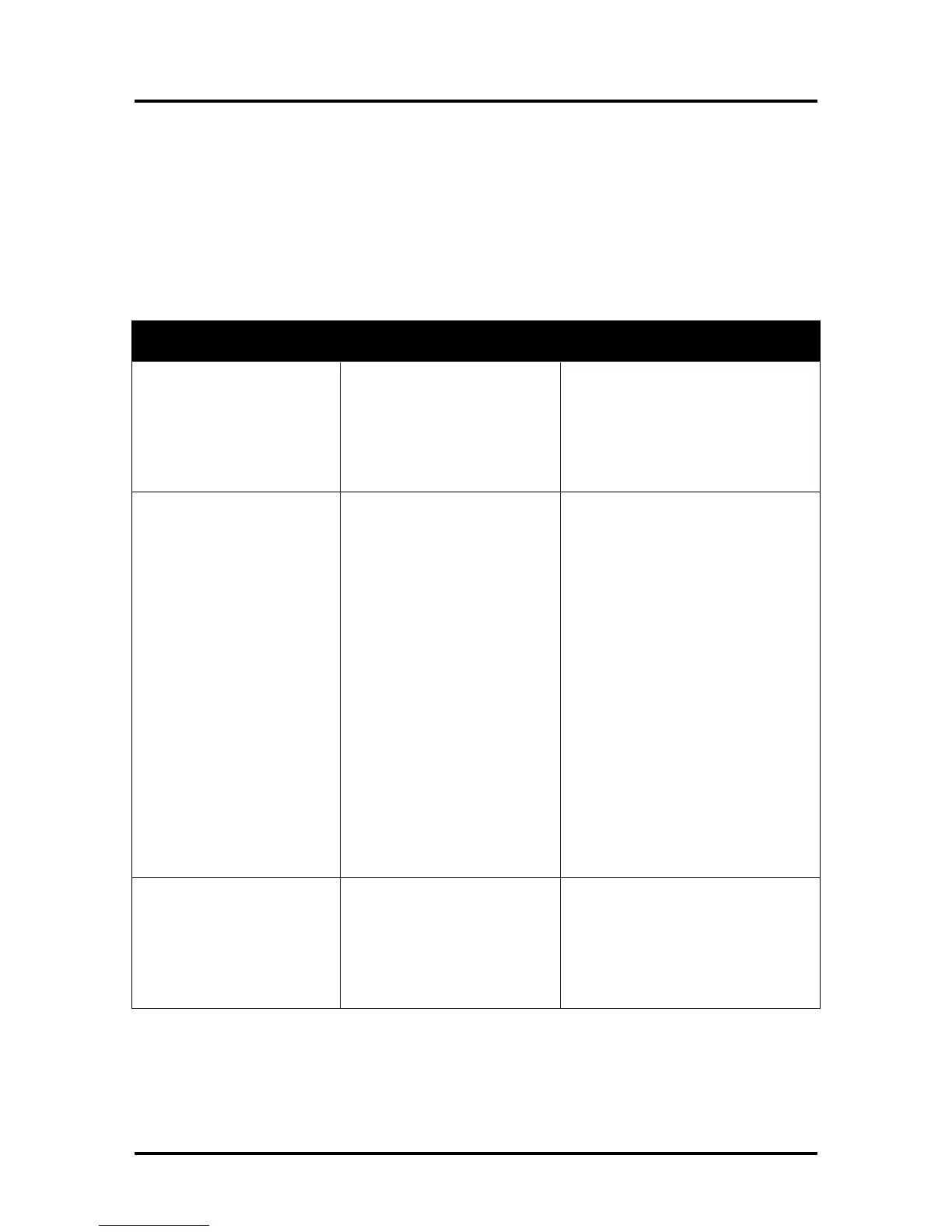

Dots or Lines Printed on Media

Multiple horizontal black

lines are printed down the

length of the media.

You have exceeded the

maximum print width of 8.5”.

Reduce paper width to 8.5” to avoid

exceeding the max print width of

printer.

NOTE: This symptom only occurs

with older firmware. Contact Tier 2

Support to update the printer’s

firmware.

A thick horizontal black line

is printed at or near the

trailing edge of the media.

Purge Bar (intrapage spitting) is

hitting trailing edge of media.

Media is hesitating or skewing

during transport.

Hole in media is passing over

the Paperpath Entry sensor.

Media is oddly shaped (running

media with open flap at trailing

edge).

To help keep nozzles from drying

(clogging); all nozzles of the printhead

are purged, between each page

(intrapage spitting).

Check/adjust media feed setup.

Check for proper install of Forwarding

Roller Guide Assembly.

Check for obstruction within the Print

Engine.

Rotate media and image so hole in

media does not travel over the

Paperpath Sensors.

Adjust the “Purge Bar Position” value;

located in the User Interface Menu of

the Toolbox.

Default = 3000. If you don’t see this

feature in the User Interface Menu;

please contact Tier 2 support to update

the printer’s firmware.

Use compatible media.

Very small dots (gray

overspray) are being printed

down length of media.

These dots are formed by

interpage nozzle spitting.

Controlled by the KWS (Keep

Wet Spitting) setting.

Interpage (on the page) nozzle spitting

is normal. This feature is used to help

keep nozzles from drying (clogging).

With firmware version 110928_u and

higher the Toolbox provides a “KWS

Setting” that can be used to adjust the

Level of spitting.

Loading...

Loading...