Setting up Compax3

C3I12T11

192-120113 N08 C3I12T11 - December 2010

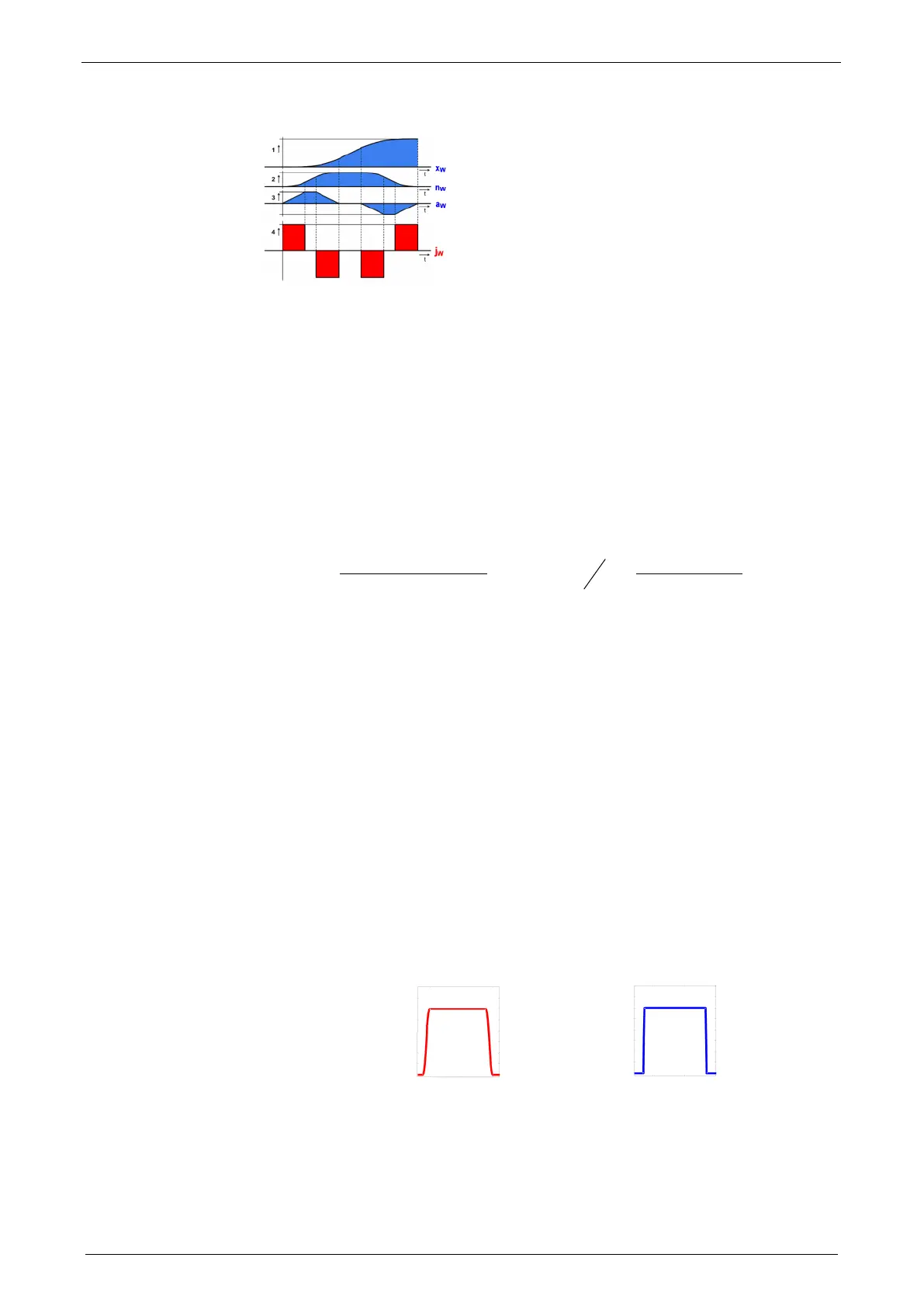

Motion profile at jerk-controlled setpoint generation

x

W

Position

n

W

Velocity

a

W

Acceleration

j

W

Jerk

The drive cannot move randomly through hard profiles, as certain physical limits

exist for the acceleration ability due to the motor physics and the limitation of the

control variable. You must therefore make sure that the set movement corresponds

to the real physics of the motor and of the servo drive.

As a support you can take the following physical correlation.

The calculation of the physically possible acceleration

rotary drives Linear drives

²][2

][][

²][

kgmJ

NmMNmM

rpsa

ges

LA

⋅

−

=

π

[ ]

][

][][

²

kgm

NFNF

s

m

a

ges

LA

−

=

M

A

: Drive torque of the motor F

A

: Drive force of a linear motor

M

L

: Load torque of the motor F

L

: Load force of a linear motor

J

total

: entire mass moment of inertia m

total

: Total mass of a linear motor

a: possible acceleration

The generation of the setpoint profile is jerk-controlled and jerk-limited by the

specification of the jerk.

In practice, jerk-limited setpoint generation is important if the items to be moved

must be handled gently. In addition, the service life of the mechanical guiding

system will be extended. A separate setting of jerk and slope of the deceleration

phase also permits overshoot-free positioning in the target position. For this

reason, it is common practice to use higher values for acceleration and jerk in the

acceleration phase than in the deceleration phase. In consequence a higher cycle

rate can be achieved.

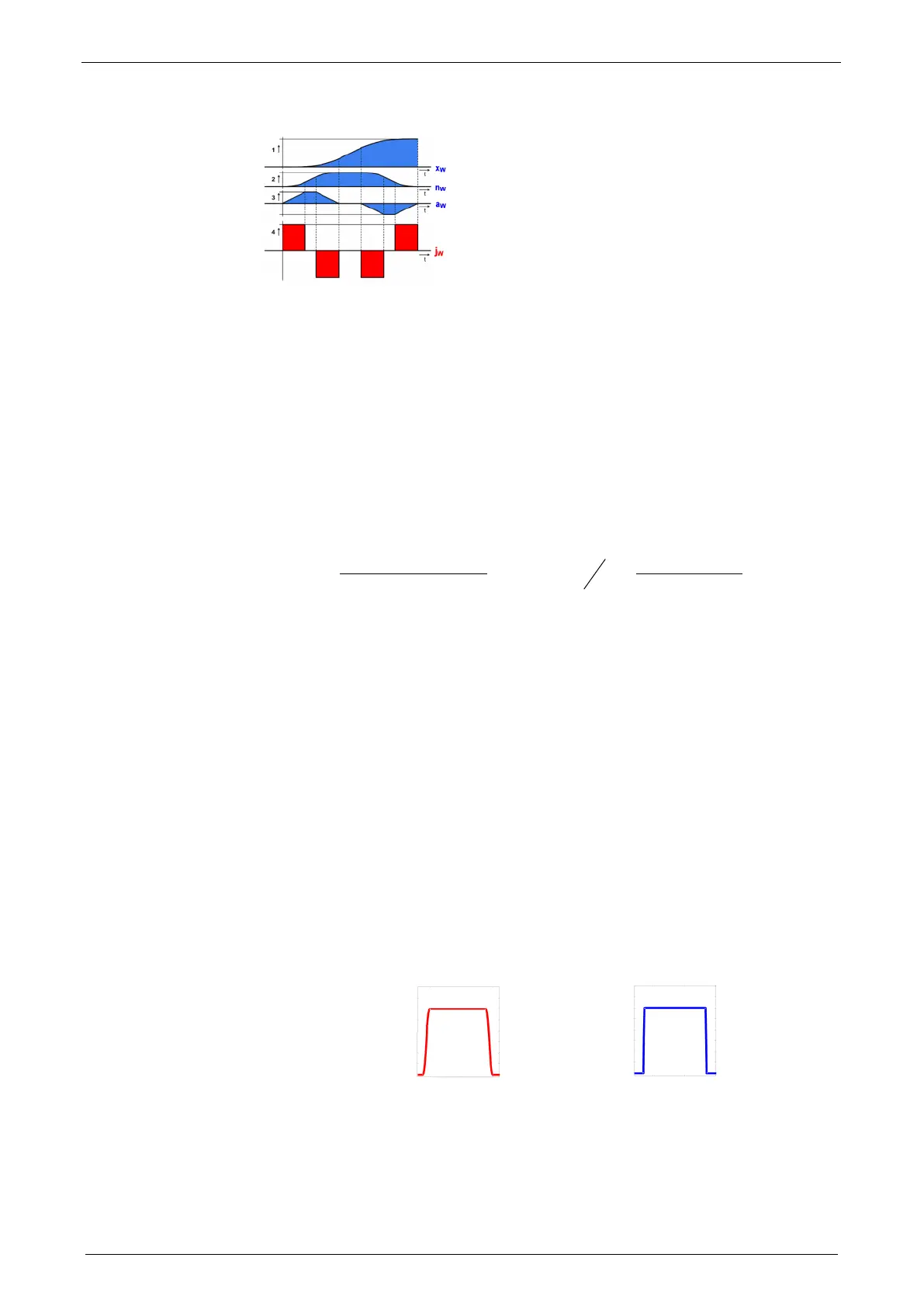

An additional important reason for the jerk limitation is the excitation of higher

frequencies due to the too high jerk in the power density spectrum of the velocity

function.

Jerk=1000°/s

3

Jerk=1000000°/s

3

Time function:

Loading...

Loading...