8-30 Motors Rexroth EcoDrive Cs Drives

DOK-ECODR3-DKC**.3-CS*-PR02-EN-P

Please observe the instructions on putting the holding brakes into

operation described in the chapter entitled “Startup, Operation, and

Maintenance”.

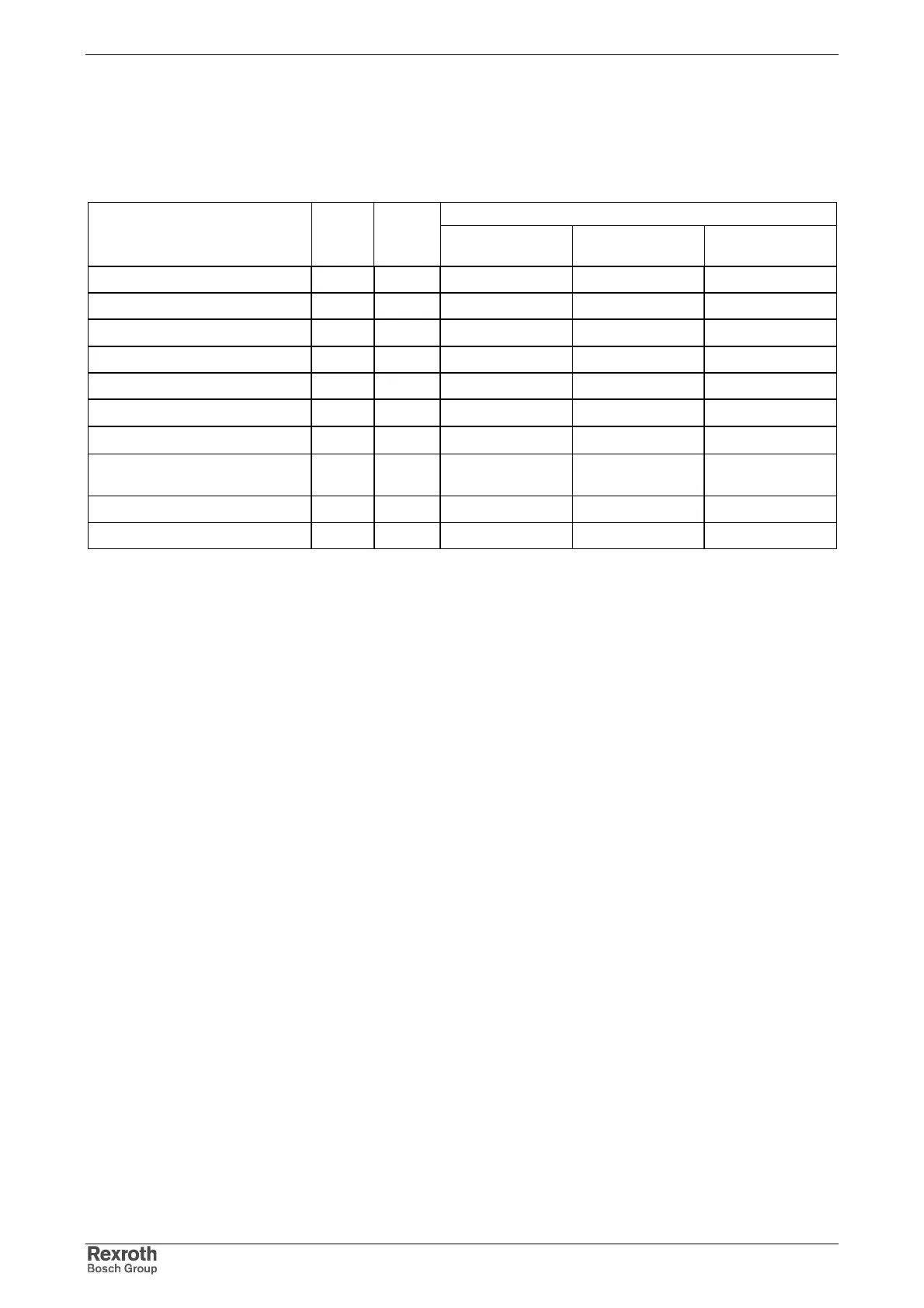

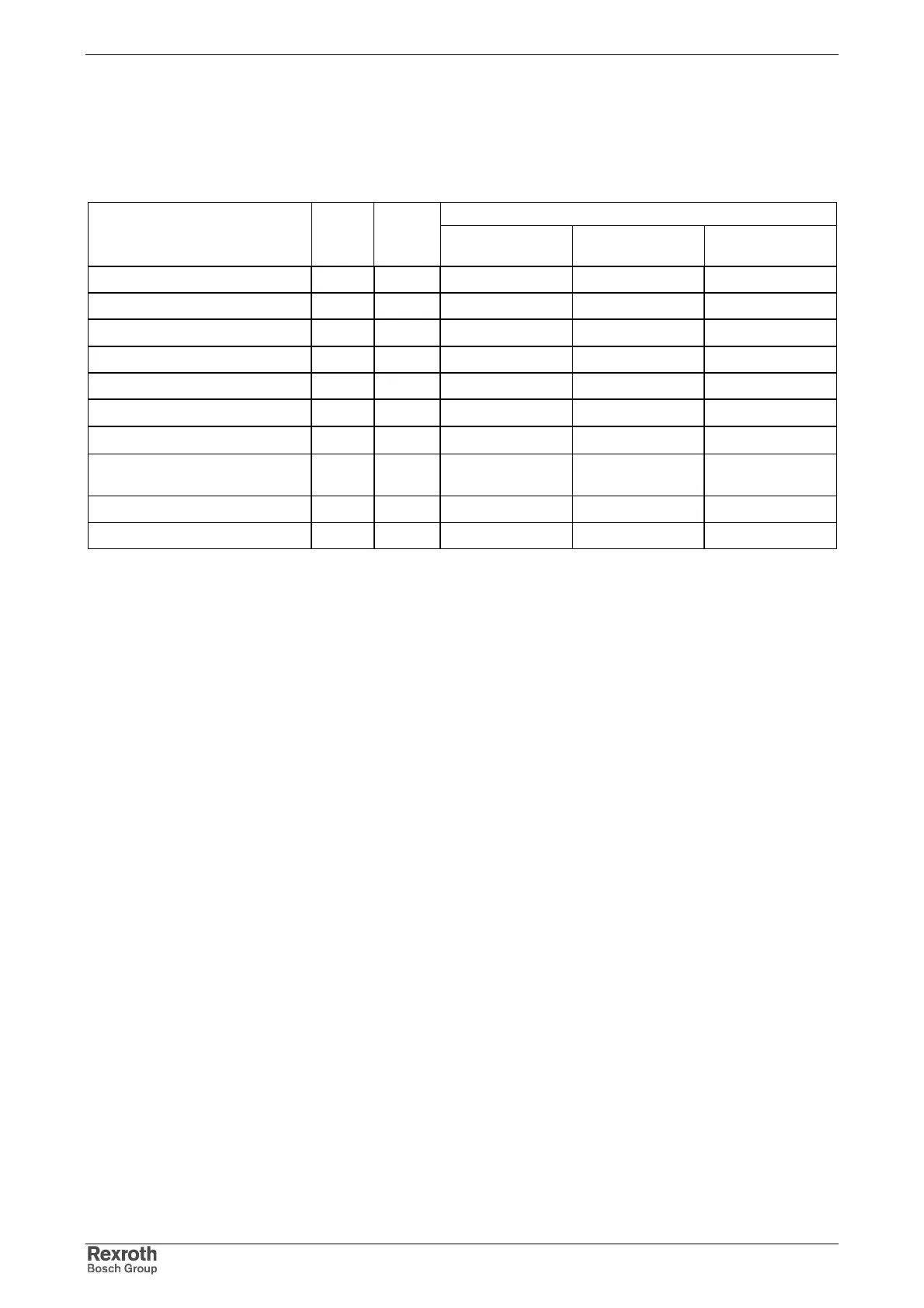

Data

Holding brake dataDesignation Symbol Unit

MSM020B MSM030B;

MSM030C

MSM040B

holding torque M

4

Nm 0.29 1.27 2.45

tripping voltage V > 1 > 1 > 1

rated voltage U

N

V

24 ±10% 24 ±10% 24 ±10%

rated current I

N

A 0.26 0.36 0.43

moment of inertia J

B

kgm

2

0.003 0.03 0.09

clamping delay t

1

ms

≤ 25 ≤ 50 ≤ 60

release delay t

2

ms

≤ 20 ≤ 15 ≤ 15

allowed braking energy (once per

braking operation)

J 39.2 137 196

allowed braking energy (total) J 4.9 x 10

3

44.1 x 10

3

147 x 10

3

allowed angular acceleration rad/s

2

10000 10000 10000

all data based on an ambient temperature of 20 °C

Fig. 8-41: Technical data of holding brake

• The above values are typical values, except for holding torque, tripping

voltage and rated voltage.

• When the motor was moved the play of the brake is ±1°

or less.

• The power supply of the holding brake is realized externally.

• Maximum number of acceleration and braking processes with the

highest allowed angular acceleration: 10 million.

Output Shaft and Motor Bearing

Plain shaft

The standard design recommended for MSM motors provides a friction-

locked shaft-hub connection without play and excellent running

smoothness. Use clamping sets, clamping sleeves or clamping elements

to couple the machine elements to be driven.

Output shaft with key

The optional key permits keyed transmission of torques with constant

direction, with low requirements for the shaft-hub connection.

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Loading...

Loading...