5-12 Electrical Connections Rexroth EcoDrive Cs Drives

DOK-ECODR3-DKC**.3-CS*-PR02-EN-P

X4, Encoder

Technical Data of the Terminal Connector

TX

RX

S20

2

1

ON

X4

X5

X6

9

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

ADDRESS

NODE

00

Rexroth

ECODRIVE

Cs

S1

H1

S2

S3

LINE ERROR

X20

X21

X4

X5_3 X5_2 X5_1

INPUTíF200V-240V

X3 X2 X1

X6

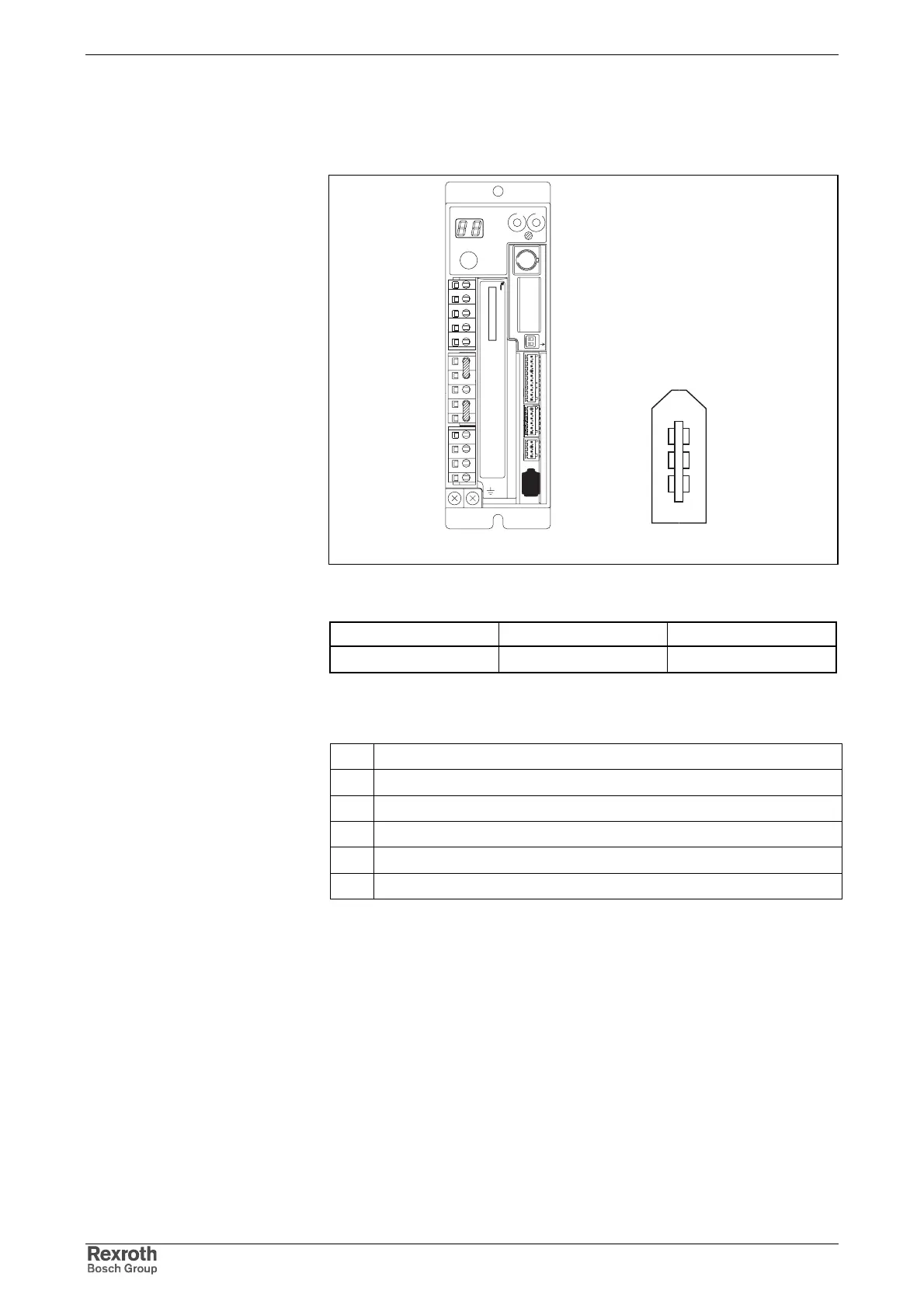

schnittstellen_X4.fh7

X4

65

43

21

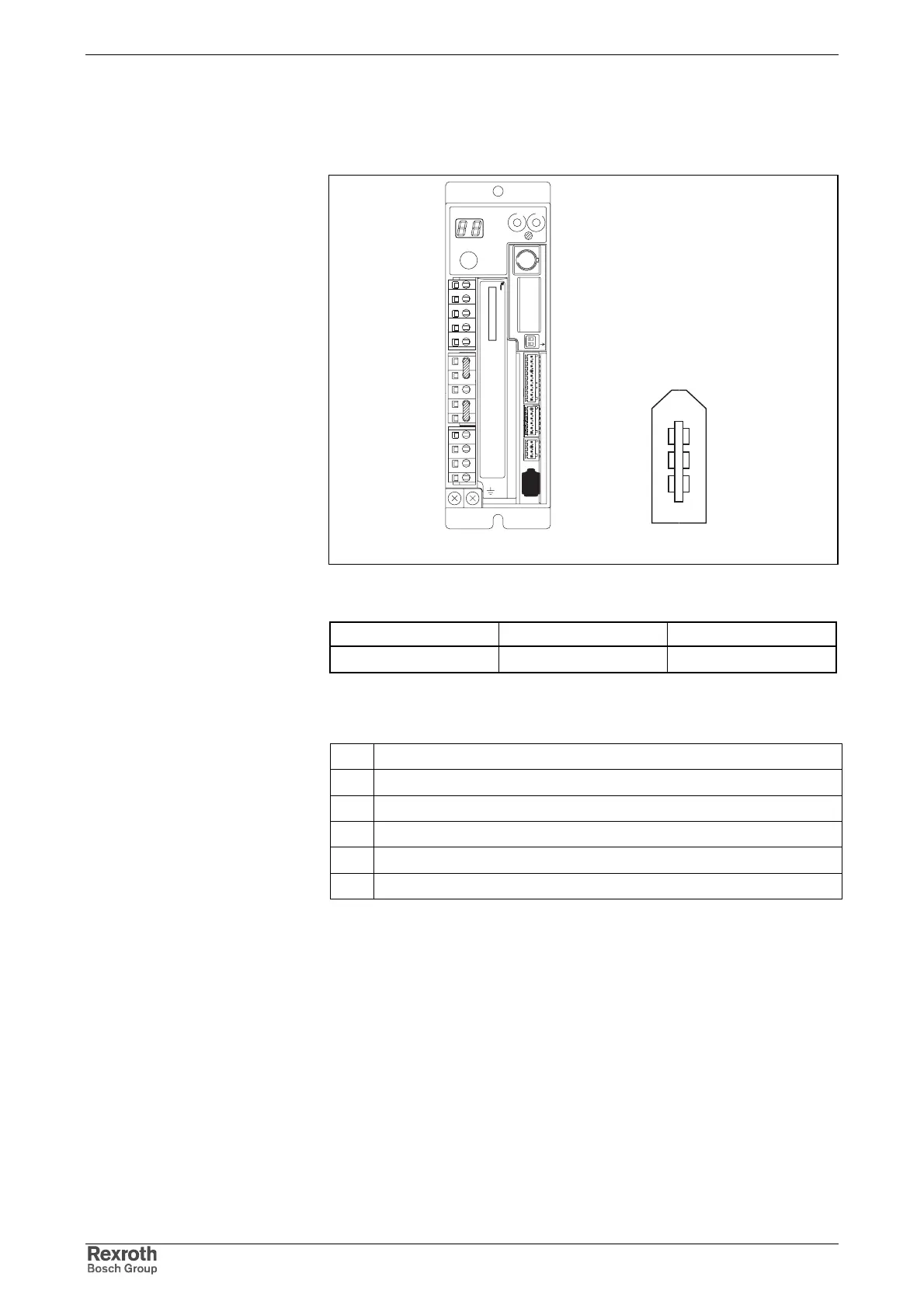

x4_molex.fh7

Fig. 5-21: Terminal connector X4

Type Number of poles Type of design

socket 6 socket on device

Fig. 5-22: Design

Connectors

1 encoder voltage supply output (5V)

2 encoder voltage supply output (0V)

3 positive pole of battery*

4 negative pole of battery*

5 encoder signal input (PS)

6 encoder signal input (PS negated)

* battery not required if the absolute encoder is used as an incremental encoder;

the battery is set into the drive controller (see chapter "Motors" → "Startup,

Operation, and Maintenance" → "Maintenance" → "Battery")

Fig. 5-23: Encoder connection

shield is grounded by means of shielding plate in connector

maximum allowed length of encoder cable: 40 m

data for encoder cable: see chapter 10.1

Graphic Representation

Design

Encoder Connection

Shield Connection

Encoder Cable

Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com

Loading...

Loading...