SYNAX200 Drive Configurations 7-17

DOK-SYNAX*-SY*-07VRS**-PR01-EN-P

7.10 Example

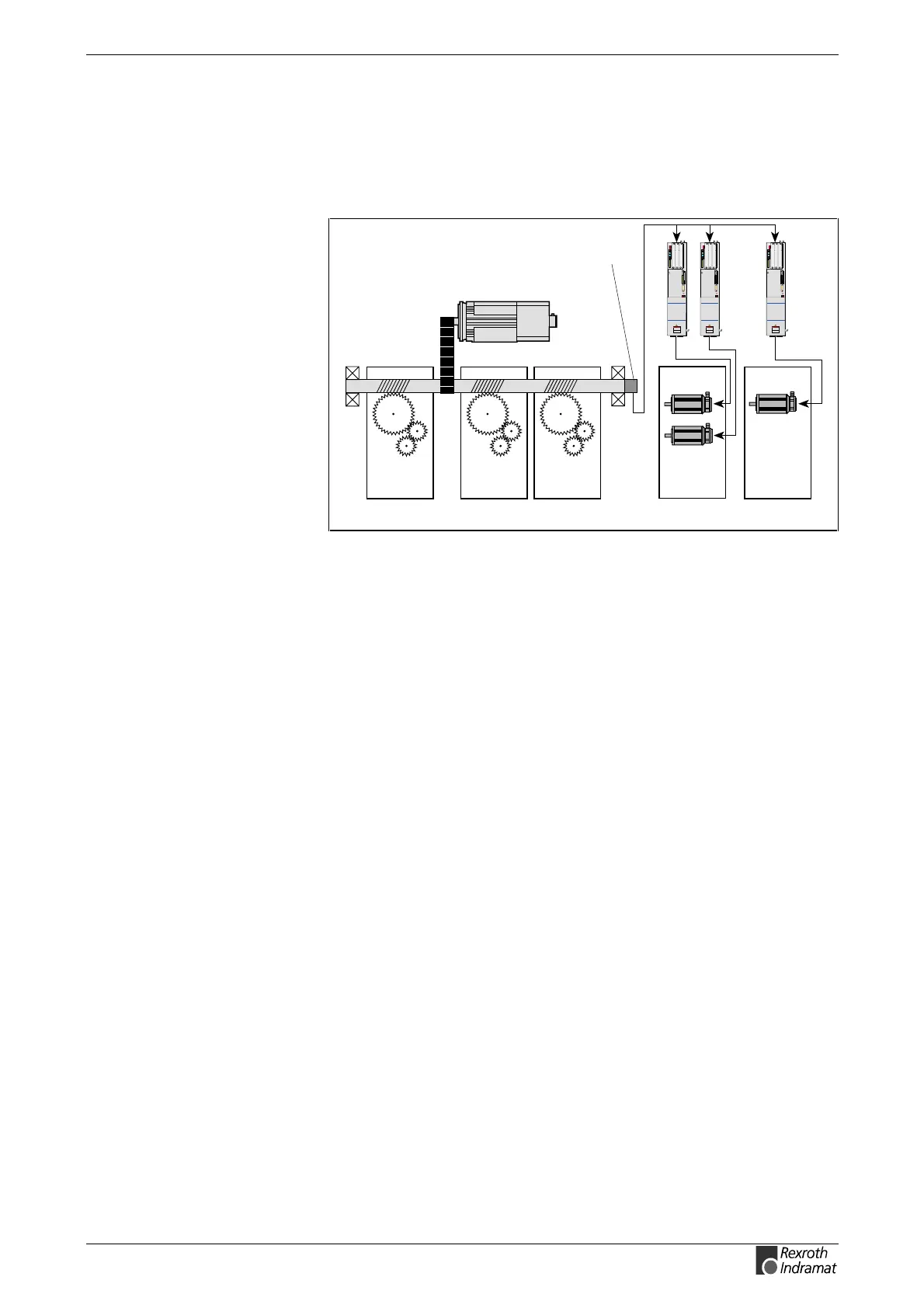

The rotary press and folding machine of the plant shown in Fig. 7-17

should be equipped with the SYNAX200 system.

SY6FB002.FH7

rotary

die-cut

folder

phase encoder

feeder

printing

unit 2

printing

unit 1

Read and follow

Instructions for Electrical Drives"

manual,

DOK-GENERL-DRIVE******-SVS...

DANG

High oltage.

Danger of electrical shock.

Donottouch electrical connections

for

5 minutes after switching

Read and follow

Instructions for Electrical Drives"

manual,

DOK-GENERL-DRIVE******-SVS...

DANG

High oltage.

Danger of electrical shock.

Donottouch electrical connections

for

5 minutes after switching

Read and follow

Instructions for Electrical Drives"

manual,

DOK-GENERL-DRIVE******-SVS...

DANG

High oltage.

Danger of electrical shock.

Donottouch electrical connections

for

5 minutes after switching

Fig. 7-17: Printing machine partially equipped with individual drives

Motion Control Configuration

The PPC-R is used as a motion control with 3 slots. One slot of the PPC-

R is assigned with the ARCNET and the PPC link assembly (DAQ)

An input module RME with 16 inputs and an output module RMA with 16

outputs are used for I/O.

A mounting rack with 4 slots is used for taking up the motion control and

the I/O modules.

How to Order the Motion Control Configuration

Pos. 1 motion control PPC-R02.2N-P1N-Q1-NN-NN-FW

Pos. 1.1 relevant firmware FWA-PPCR0*-SY*-07VRS-MS

Pos. 2 input module RME02.2-16-DC024

Pos. 3 output module RMA02.2-16-DC024-200

Pos. 4 mounting rack RMB02.2-04

Loading...

Loading...