5-12 Determining Basic Drive Configuration SYNAX200

DOK-SYNAX*-SY*-07VRS**-PR01-EN-P

Drive with Direct Incremental Position Detection

• no gear between motor and cylinder

• high level of precision can be achieved

• load angle directly determined via incremental external encoder

• gear error statically compensated

• With MHD, MKE, MKD and MBS motors:

- motor encoder for commutation is needed

- absolute position detection via motor encoder

• With MBW, 1MB, 2AD and ADF motors:

- no separate motor encoder

- no absolute position detection

• With MBW and 1MB motors:

- rigid coupling between motor and cylinder, resulting in

highest level of static and dynamic stiffness

Usable Motors DKR:

• MBW (without motor encoder)

• 1MB (without motor encoder)

• 2AD (without motor encoder)

• ADF (without motor encoder)

• MBS (only in connection with motor encoder)

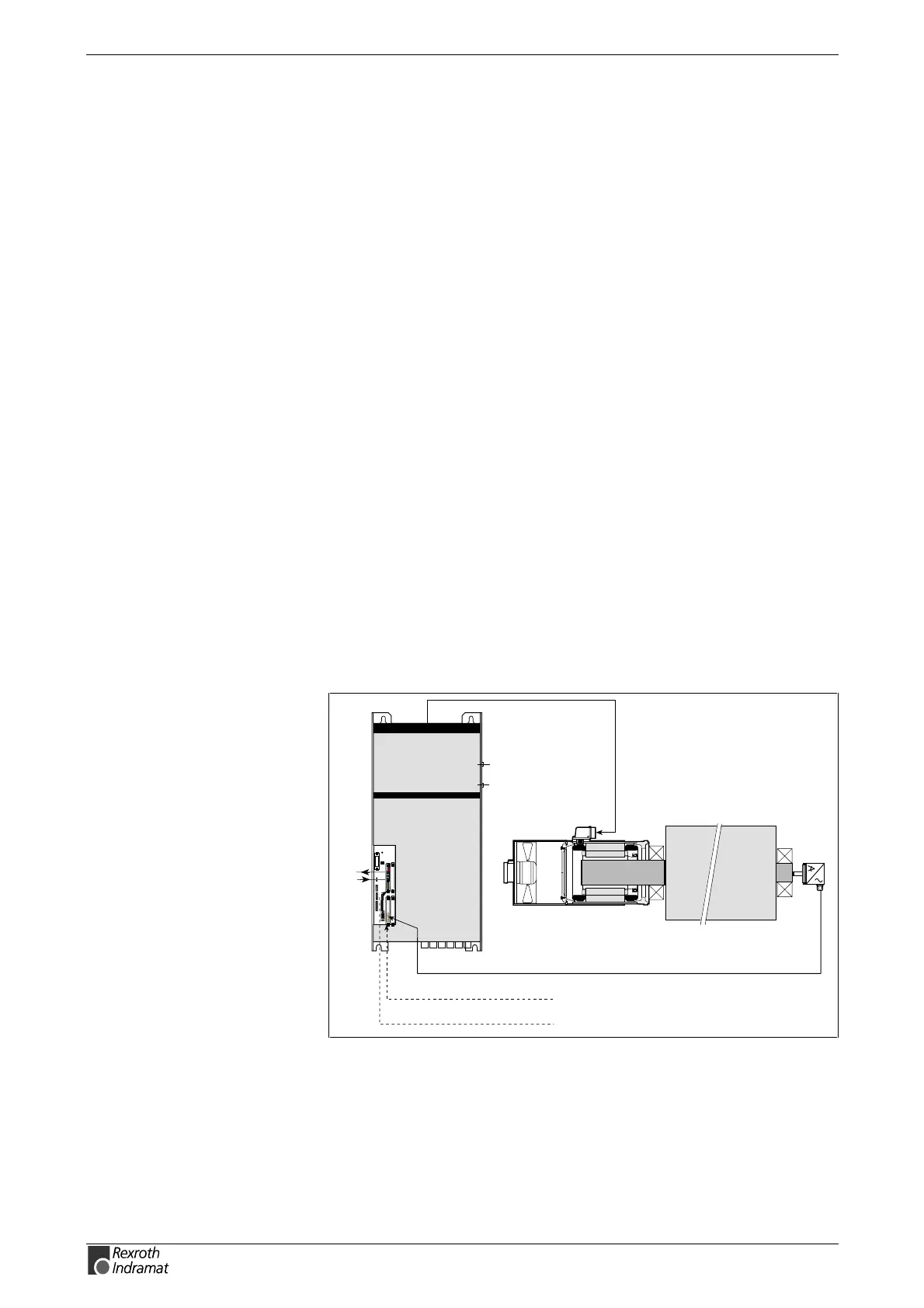

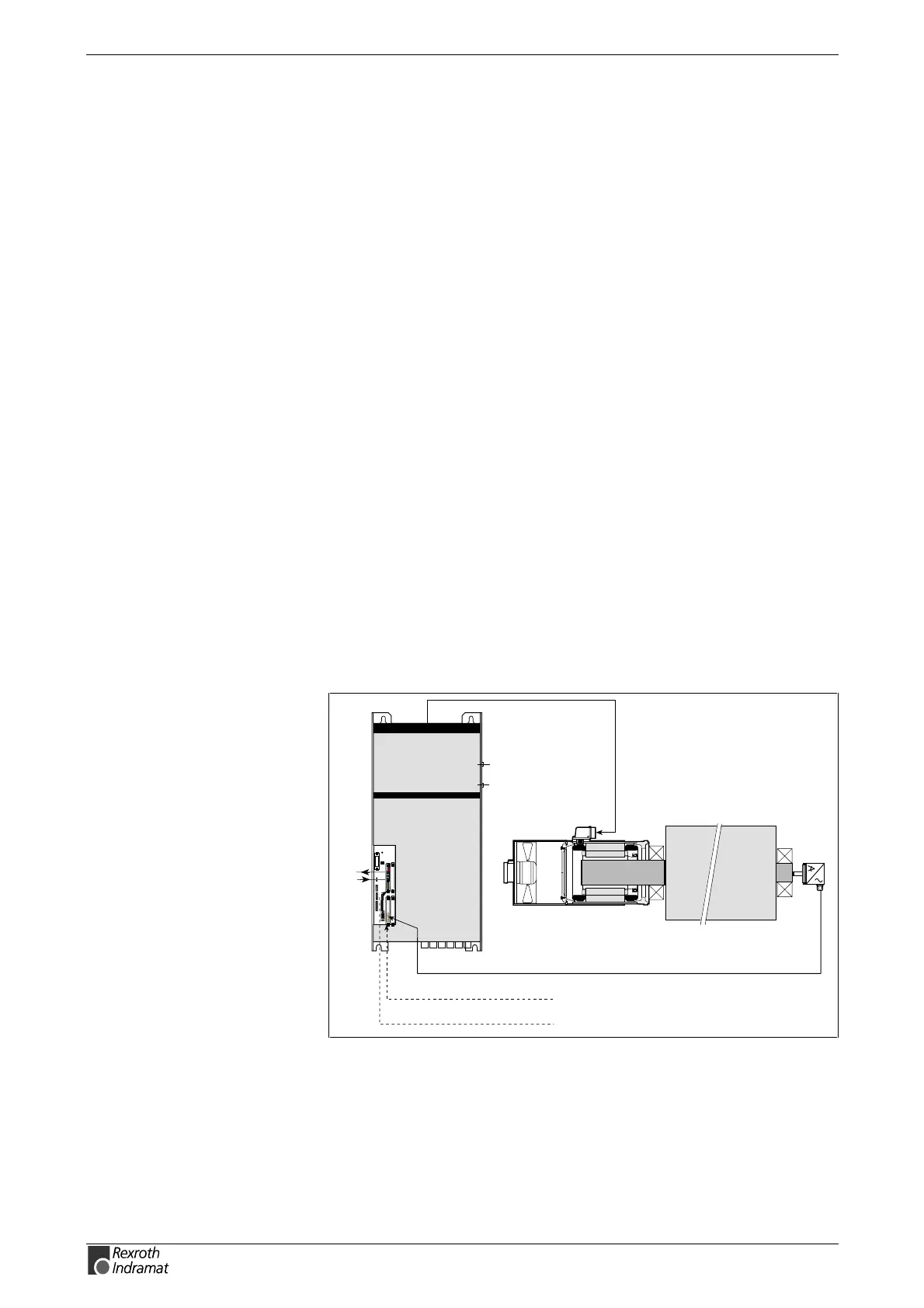

Basic Drive Configuration BE32 (DKR)

SY7PR006.FH7

MBW

2AD

ADF

1MB

LWL

U1 (DSS)

U2 (DLF)

IKS 349

DIGITAL COMPACT CONTROLLER

DKR 4

H1

X4

X2

U5

U2

S2

U4

U1 U3

X9

1

6

1

7

X8

H2

S1

X3

X7

1

10

1

11

X3

external

incremental encoder

with sine output

e.g., Heidenhain

ROD 481

ERN 180

ERN 680

RON 285

Fig. 5-13: Drive with MBW, 2AD or 1MB motor with direct incremental position

detection

Features:

MBW, 2AD, ADF, 1MB:

Loading...

Loading...