2-6 Frame 2 Installation

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

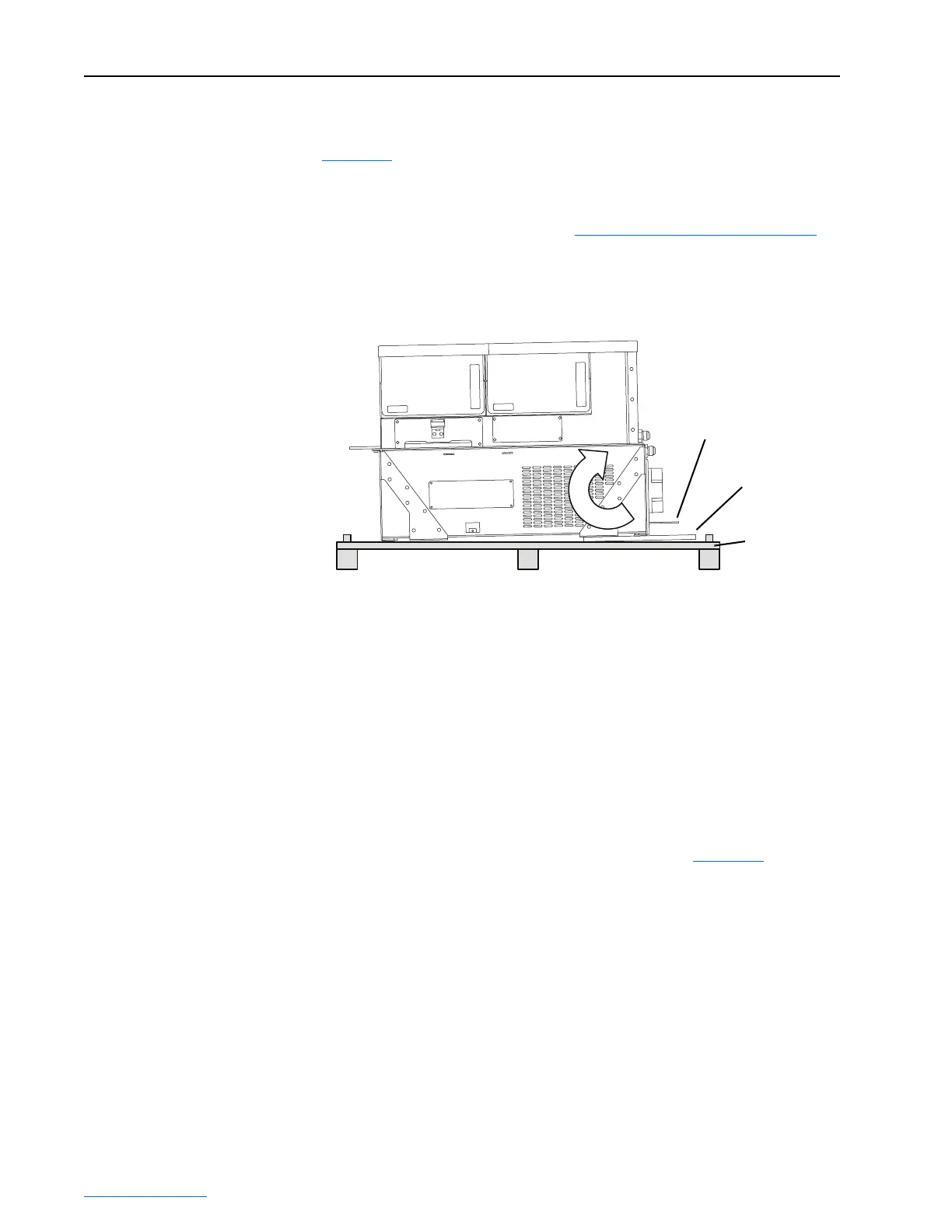

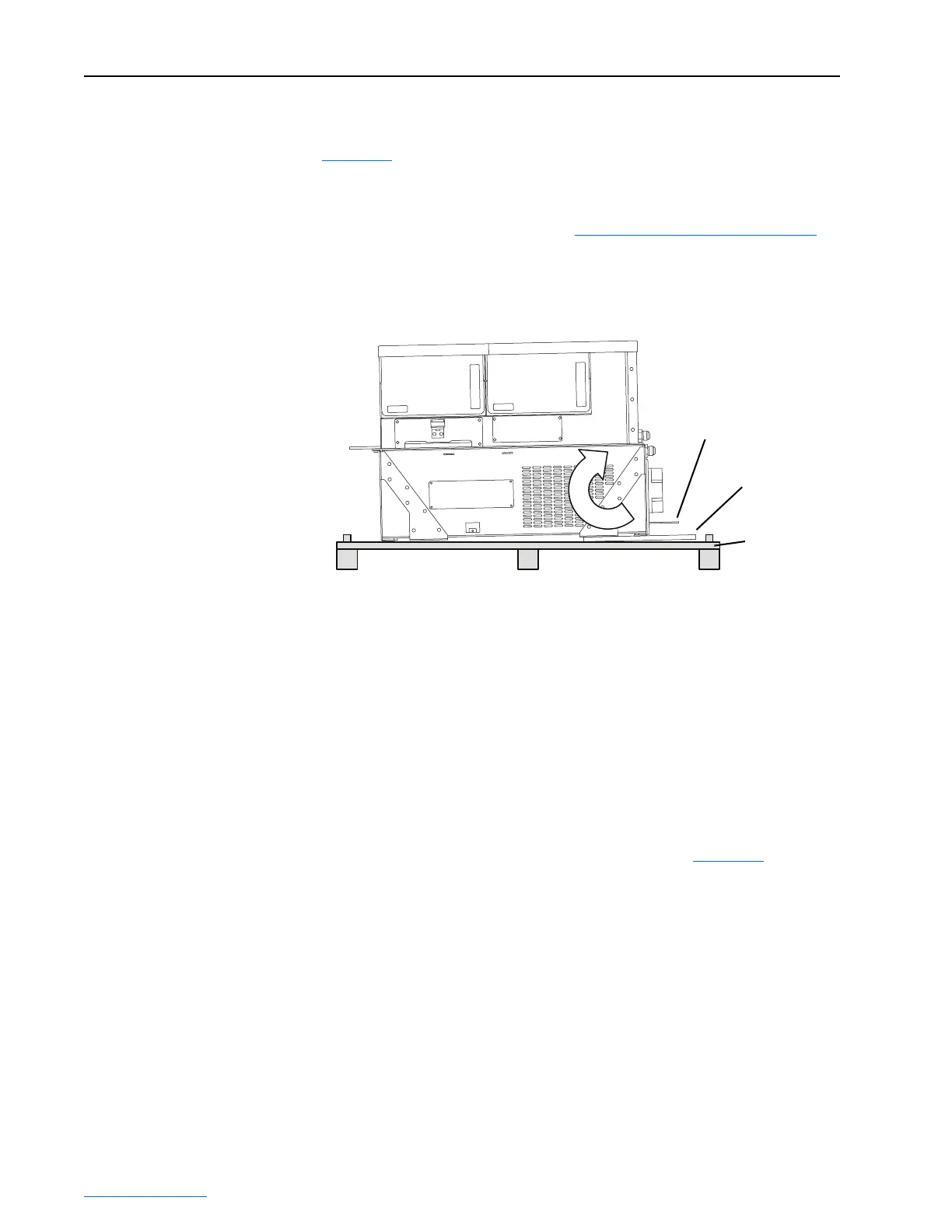

Rotating the Drive About the Board

Figure 2.6 shows the drive, with the lifting feet attached, on a skid. To avoid

damage to the drive input terminals when lifting the drive to a vertical

position, do the following:

1. After the straps are in place (see Applying Strap Angles

on page 2-5),

carefully lift the drive to rotate it 90° to a vertical position.

2. Remove the lifting feet before installing the drive into the enclosure.

Figure 2.6 Frame 2 Drive on Skid

Mounting Requirements

The PowerFlex700L Frame 2 drive is a single integrated assembly

consisting of a filter section and a power section. The filter section provides

the mounting feet and represents greater than 50% of the approximate 186

kg (410 lb.) total weight.

1. The Frame 2 drive should be mounted into an enclosure that is designed

according to Electrical Equipment Pollution Degree 2 requirements.

2. Any enclosure mounting panel needs to be sized and fastened

appropriately to accommodate for the weight of the drive.

3. The Frame 2 drive is designed to use eight M8 x 1.25 fasteners in

mounting slots shown in Detail A and Detail B of Figure 2.1

.

4. The M8 x 1.25 fasteners shall be class 5.8 or greater.

5. The fasteners shall use a lock washer or similar mechanism to prevent

loosening after mounting.

6. All M8 x 1.25 fastener threads shall engage a steel panel with 6 - 7 full

threads or a permanent backing nut such as a weld nut or a

self-clinching PEM

®(1)

nut with 4 full threads.

7. M8 x 1.25 fasteners shall be tightened to 11.3 ± 2.8 N•m (100 ± 25

in•lbs) unless the lock washer mechanism requires a different torque. If

this is the case, the holding force shall be equivalent.

Skid

Input Terminals

Lifting Feet

(1)

PEM is a registered trademark of PennEngineering.

Loading...

Loading...