Cooling Loop Installation 4-7

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

Drive Coolant Requirements

Recommended Coolants

Table 4.F lists approved sources and recommended coolants with

appropriate corrosion inhibitors

for the drive loop:

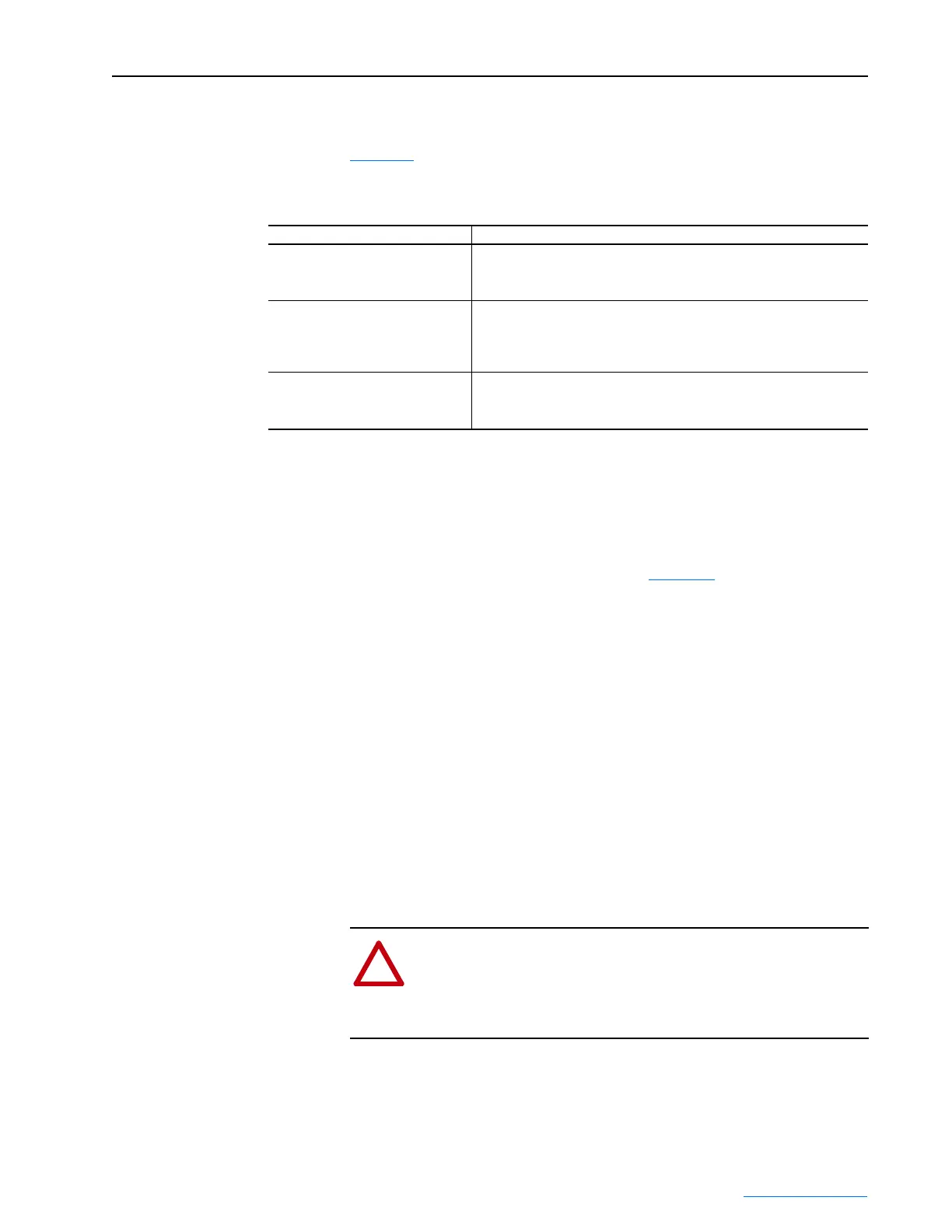

Table 4.F Recommended Drive Loop Coolants

Non-premixed coolants require a coolant-to-water mix ratio of 50% by

volume.

For an estimated amount of coolant needed for Allen-Bradley 20L-LL*

Liquid-to-Liquid Heat Exchangers, refer to Table 4.B

.

Important: Since coolant performance slowly degrades over time, the drive

loop coolant should be replaced every two years and/or

whenever the loop is drained for servicing.

Corrosion Inhibitor

If an approved coolant is not used, the drive coolant must consist of clean

water with a corrosion inhibitor. An approved corrosion inhibitor is

Chemtool, Inc. (www.chemtool.com) part number Watertool 4435-C. The

recommended concentration of the inhibitor is 8-10% by volume. Deionized

water is prohibited. Use distilled water or water with less than 50 ppm

concentrations of:

• Sulfate and chloride

• Hard water ions such as Mg++ and Ca++

Source Coolant

Interstate Chemical

http://www.interstatechemical.com/

contact.htm

• NFP-50

(1)

; a 50/50 premix of propylene glycol and distilled water

• NFE-50

(1)

; a 50/50 premix of ethylene glycol and distilled water

Koolant Koolers/Dimplex Thermal

Solutions

http://www.koolantkoolers.com/

index.php/nic=contact

• K-Kool-E

(1)

; ethylene glycol (available premixed with distilled water)

• Propylene glycol

(1)

also available

Dow Chemical

http://www.dow.com

• Dowtherm

®

SR-1

(2)

; ethylene glycol

• Dowfrost

®

(2)

; propylene glycol

Dowtherm and Dowfrost are registered trademarks of the Dow Chemical Company

(1)

Available in 5 gallon pails.

(2)

Not premixed with distilled water, and may not be available in 5 gallon quantities.

!

ATTENTION: Ethylene and propylene glycols must be

inhibited and silicate free. Use of common silicate-containing,

automotive-type ethylene glycol solutions is prohibited as they

may damage the heat exchanger and/or drive and cooling

module equipment.

Loading...

Loading...