4-8 Cooling Loop Installation

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

The drive coolant must be compatible with the following materials:

• Copper

• Brass

• Aluminum

• Arimid fiber gasket with nitrile binder (Garlock, Inc. Blue-Gard 3000

®

)

Blue-Gard 3000 is a registered trademark of Garlock, Inc.

• Synthetic rubber hose (Parker Hannifan Corp 801 General Purpose Hose)

• Viton seal (Complete Drive only)

Biocide

A biocide may be needed to control biological growth. Use of a biocide is

permitted. For specific recommendations, consult a reputable water

treatment company.

Drive Cooling Loop Specifications

* Inhibited ethylene glycol or propylene gylcol must contain a corrosion inhibitor. See Corrosion Inhibitor on

page 4-7 for an approved source.

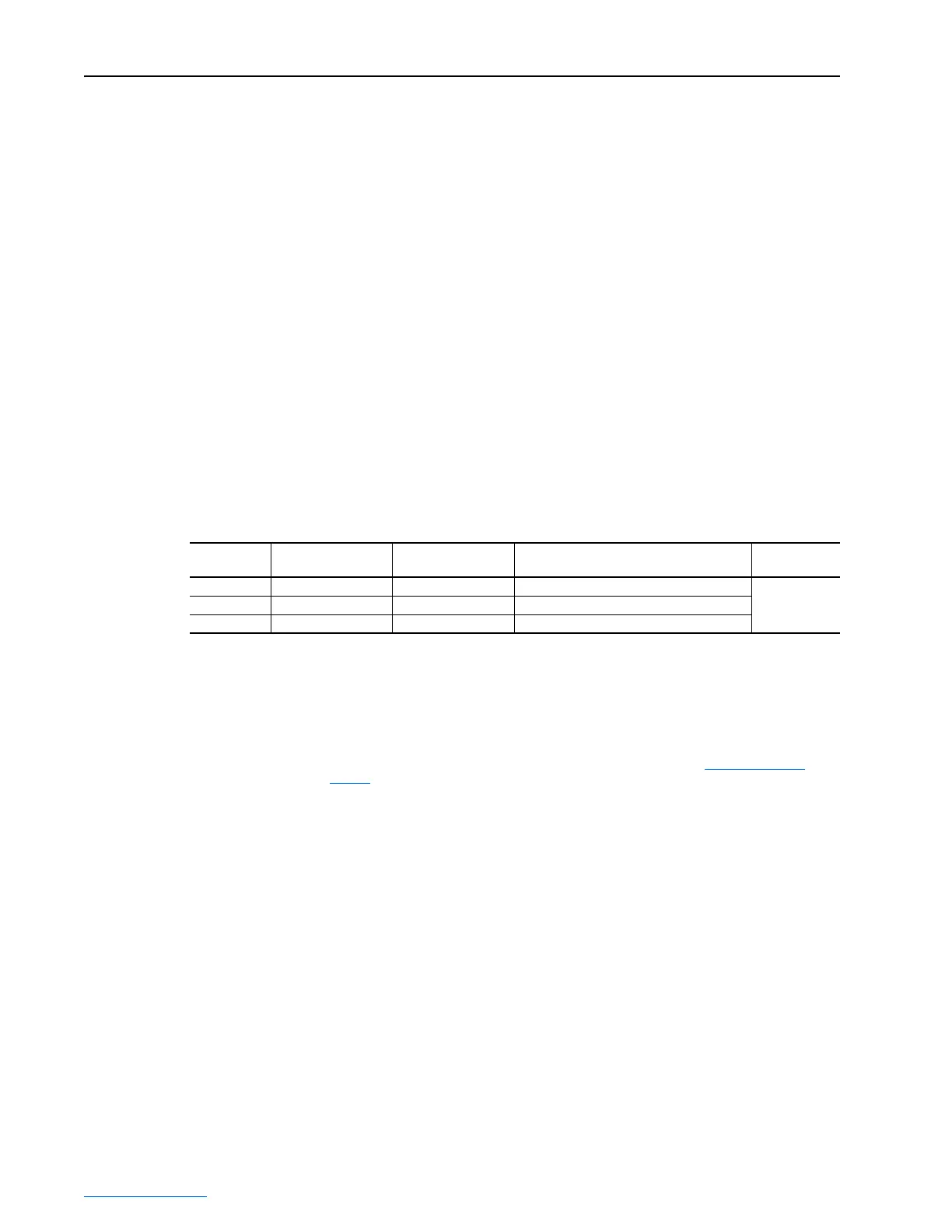

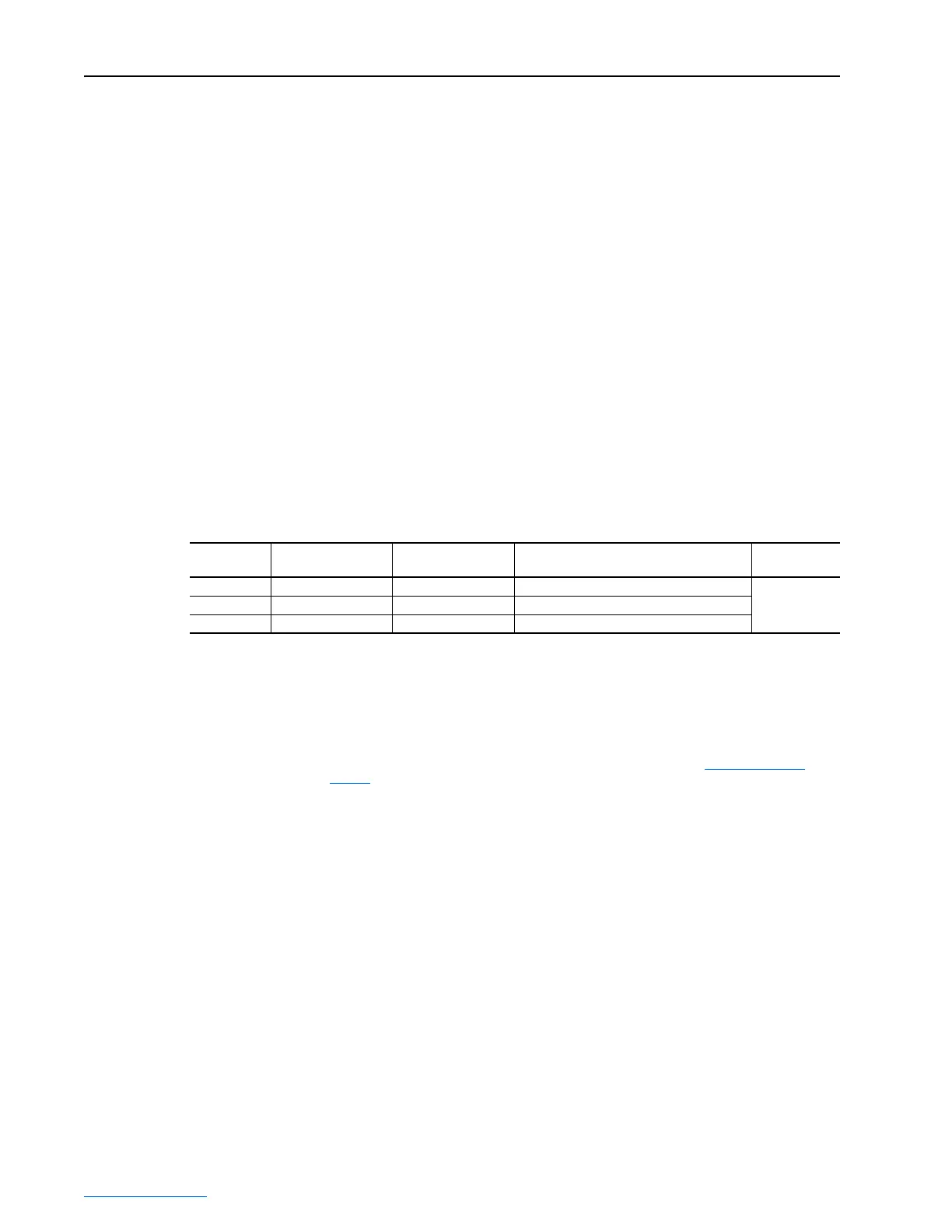

Table 4.G Coolant Requirements for One Frame 2, 3A or 3B Drive

Drive

Frame Size

Coolant

Temperature Range

Minimum Coolant

Flow Rate

Pressure Drop

(2)

From Drive Inlet to Drive

Outlet at Minimum Coolant Flow Rate

Coolant Type

2 0-50°C (32-122°F) 30.3 LPM (8 GPM) 1.58 bar (23 PSI)

WEG50

(3)

or

WPG50

(4)

3A 0-40°C (32-104°F) 30.3 LPM (8 GPM) 0.35 bar (5 PSI)

3B 0-40°C (32-104°F) 56.8 LPM (15 GPM)

(1)

0.48 bar (7 PSI)

(1)

(1)

Frame 3B includes separate converter and inverter power modules. A single inverter or converter power module requires a minimum flow rate

of 30.3 LPM (8 GPM) at 0.35 bar (5 PSI).

(2)

Pressure drop does not include any system connections such as hoses or piping. Cooling systems must be sized to provide minimum flow

considering entire system pressure drop.

(3)

WEG50 equals good quality or distilled water with approved inhibited* ethylene glycol, 50% glycol by volume.

(4)

WPG50 equals good quality or distilled water with approved inhibited* propylene glycol, 50% glycol by volume.

Loading...

Loading...