4-10 Cooling Loop Installation

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

Drive Coolant Connections

Frame 2 Drive or Frame 3A or 3B Power Module

For locations of the coolant inlet and outlet connections on PowerFlex 700L

Liquid-Cooled Frame 2 drives, refer to Figure 2.10

. For locations on Frame

3A and 3B Power Modules, see Figure 3.20

.

The rated working pressure of the Frame 2 drive is 6.89 bar (100 psig).

Coolant supply and return lines should be sized for 76 LPM (20 GPM) /

6.89 bar (100 PSI) service with a maximum operating temperature of 50°C

(122°F). The required operating flow rate and pressure drop is specified in

Table 4.G

.

The rated working pressure of the Frame 3A or 3B Power Module is 12.76

bar (185 PSI). Coolant supply and return lines should be sized for 38 LPM

(10 GPM) / 12.76 bar (185 PSI) service with a maximum operating

temperature of 40°C (105°F). The required operating flow rate and pressure

drop is specified in Table 4.G

.

Coolant connections for Frame 2 drives and Frame 3A and 3B Power

Modules are made using 37 degree flare fittings which have a:

• 3/4-inch nominal size

• “-12” SAE dash size

• 1 1/16-12 UN/UNF-2B external thread size

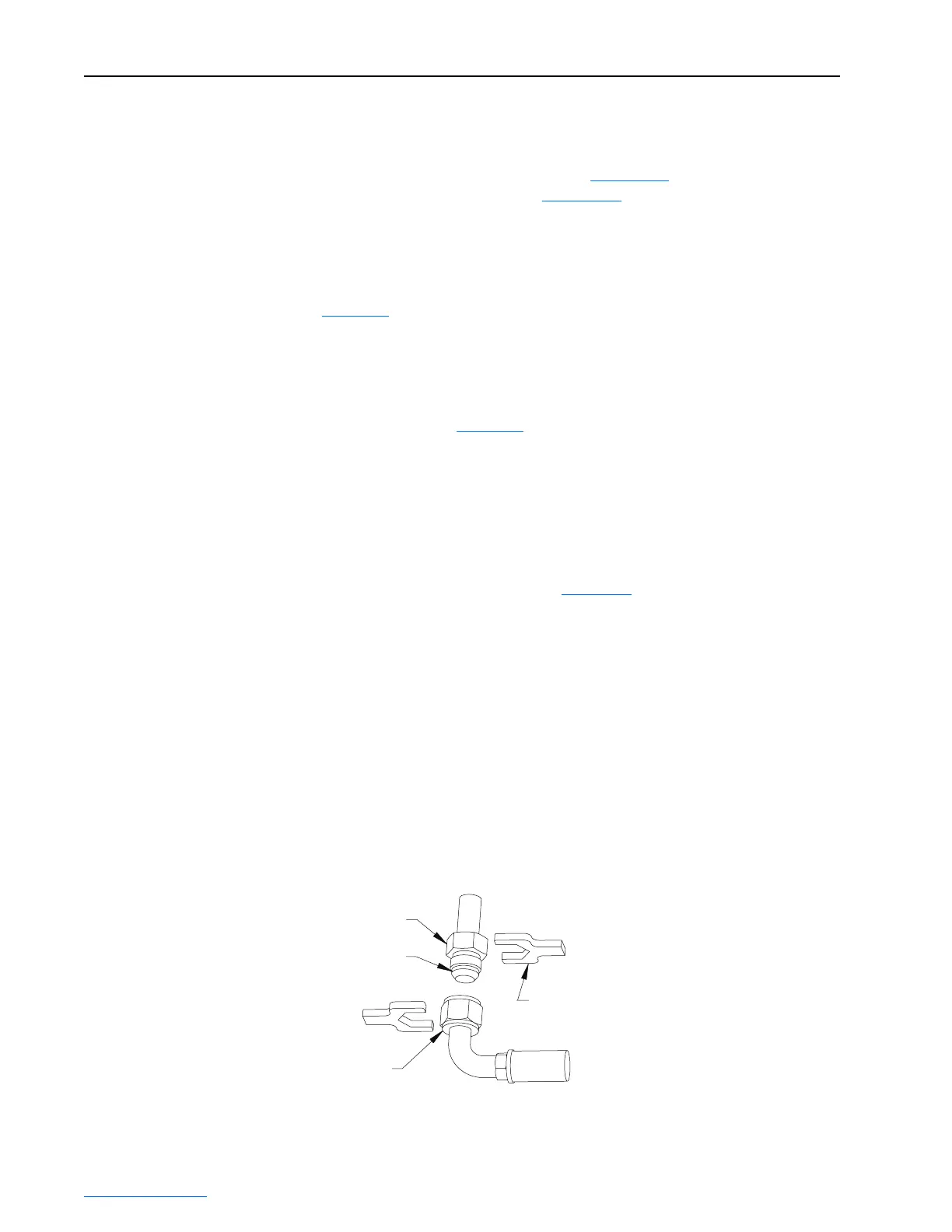

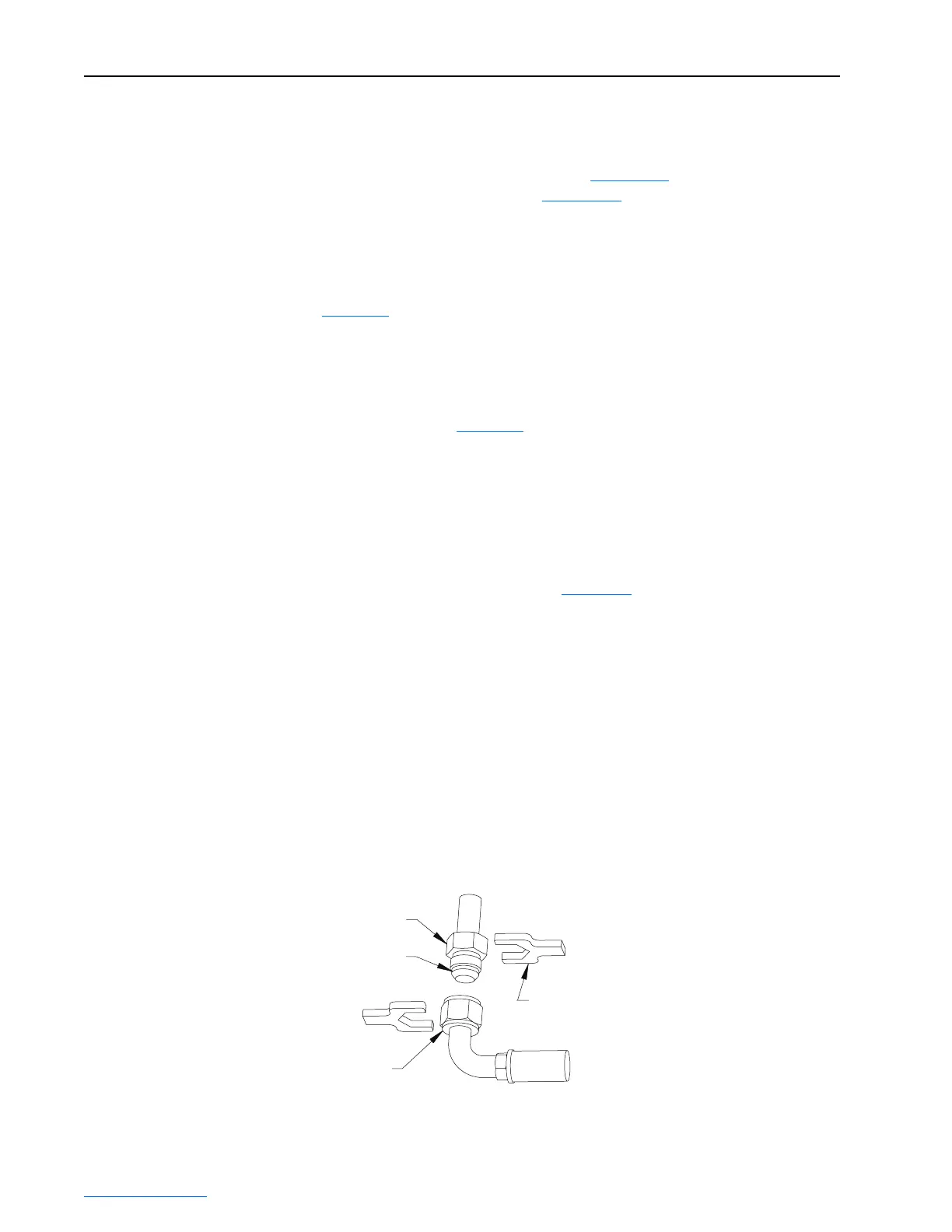

The mating connection is shown in Figure 4.7

. The mating process includes

the following steps:

1. Assemble the mating version of the fitting (with swivel nut) to each

fluid fitting, and tighten to a wrench resistance of approximately 3.4

N•m (30 lb•in).

2. Using a backup wrench on the Power Module fitting, tighten the swivel

nut fitting by either of the following two methods:

– Hex flats from wrench resistance method (recommended): one and

one-quarter (1-¼) hex flat from wrench resistance.

– Torque method: 69-77 N•m (51-57 lb•ft).

Figure 4.7 Power Module Mating Coolant Connection

37° Flare Fitting

Wrench Flats

Swivel Nut

Backup Wrench

(use to prevent twisting

during swivel nut tightening)

Loading...

Loading...