Cooling Loop Installation 4-5

PowerFlex® 700L Liquid-Cooled Drive User Manual

Publication 20L-UM001D-EN-P

The main components of the chiller cooling loop include:

Recommended Cooling

Loops

Liquid-to-Liquid Heat Exchanger

Recommended Liquid-to-Liquid Heat Exchangers from Rockwell

Automation are listed in Table 4.A

.

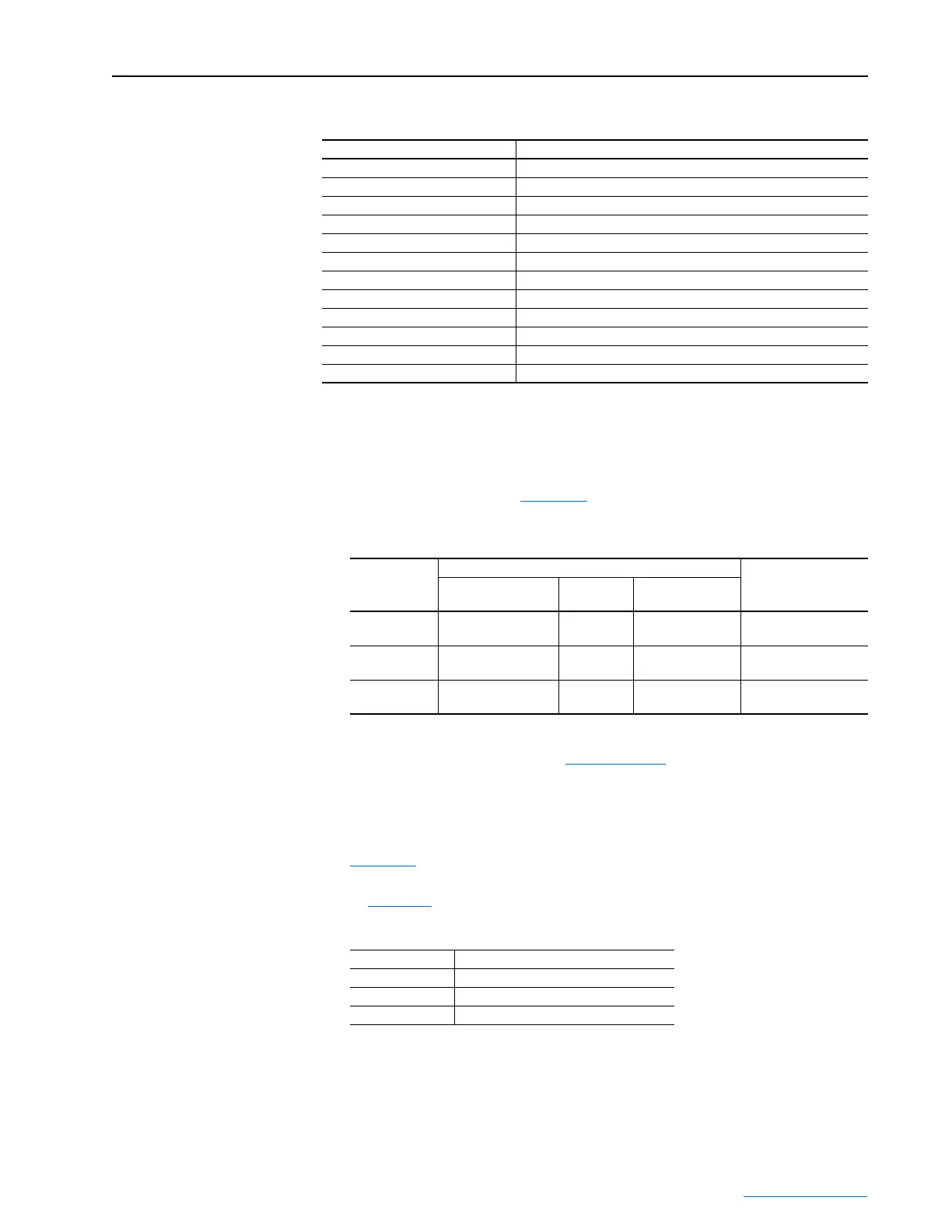

Table 4.A Liquid-to-Liquid Heat Exchanger Requirements

Table 4.B lists the estimated amount of coolant needed for the drive loop

based on the drive frame size. For recommended drive loop coolants, refer

to Table 4.F

.

Part Description

Compressor Forces the refrigerant into a smaller space.

Fan Blows air across the condenser/subcooler.

Condenser/Subcooler Cools the refrigerant.

Filter-Drier Filters the refrigerant.

Sight Glass Allows viewing of the level of drive coolant in the reservoir.

Thermostatic Expansion Valve Allows for expansion of the refrigerant.

Level Switch Senses the level of coolant in the reservoir.

Reservoir Allows for expansion of coolant.

Pump and Motor Circulates drive coolant.

Drive Coolant Temperature Sensor Senses the drive coolant temperature used for the dew point control.

Drive Coolant Flow Switch Measures the drive coolant flow rate.

Ambient Sensor Senses the ambient temperature used for the dew point control.

Drive

Frame Size

Supply Loop Requirements

(1)

(1)

Supply loop requirements are for the input to the heat exchanger. These are not requirements for the drive. The

output of the heat exchanger is designed to meet the flow and pressure requirements of the drive. For the flow

and pressure requirements of the drive, see Table 4.G on page 4-8

.

Liquid-to-Liquid Heat

Exchanger Cat. No.

(3)

(3)

Recommended cooling loops shown are based on a single drive per cooling loop. Consult the factory for use of

multiple drives on one cooling loop.

Minimum Flow @

Pressure

(2)

(2)

The minimum pressure applies to the pressure drop across the heat exchanger and does not take into account

additional pressure drop in the system such as piping or hosing.

Maximum

Pressure

Temperature

Range

2 15.1 LPM @ 0.83 bar

(4 GPM @ 12 PSI)

8.62 bar

(125 PSI)

0-40°C (32-104°F) 20L-LL13K-P75A

3A 22.7 LPM @ 0.83 bar

(6 GPM @ 12 PSI)

8.62 bar

(125 PSI)

0-35°C (32-95°F) 20L-LL13K-P75A

3B

56.8 LPM @ 0.83 bar

(15 GPM @ 12 PSI)

8.62 bar

(125 PSi)

0-35°C (32-95°F) 20L-LL24K-1P0A

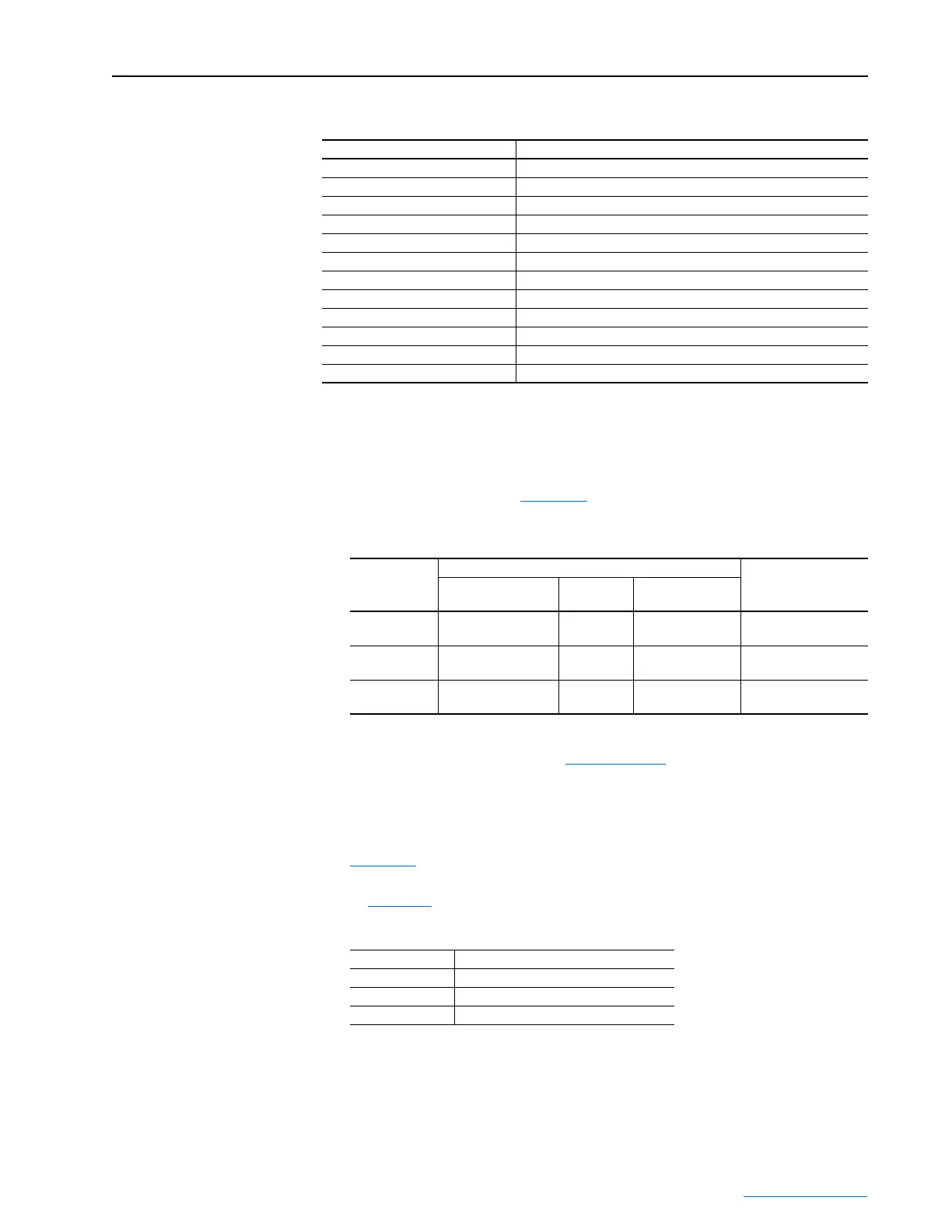

Table 4.B Estimated Coolant Amount for the Drive Loop

Drive Size Estimated Amount of Coolant

(1)

(1)

The estimated amount of coolant is based on the heat exchanger

using 1.2 m (4 ft.) hoses. Longer hoses require more coolant. The

maximum hose length of 9.1 m (30 ft.) would require up to an

additional 2.8 liters (3/4 gal.).

Frame 2 15.1 liters (4 gal.)

Frame 3A 19 liters (5 gal.)

Frame 3B 19 liters (5 gal.)

Loading...

Loading...