Product Description

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH 27

Subject to change without notice

2.3.1.3 Purged sender/receiver units

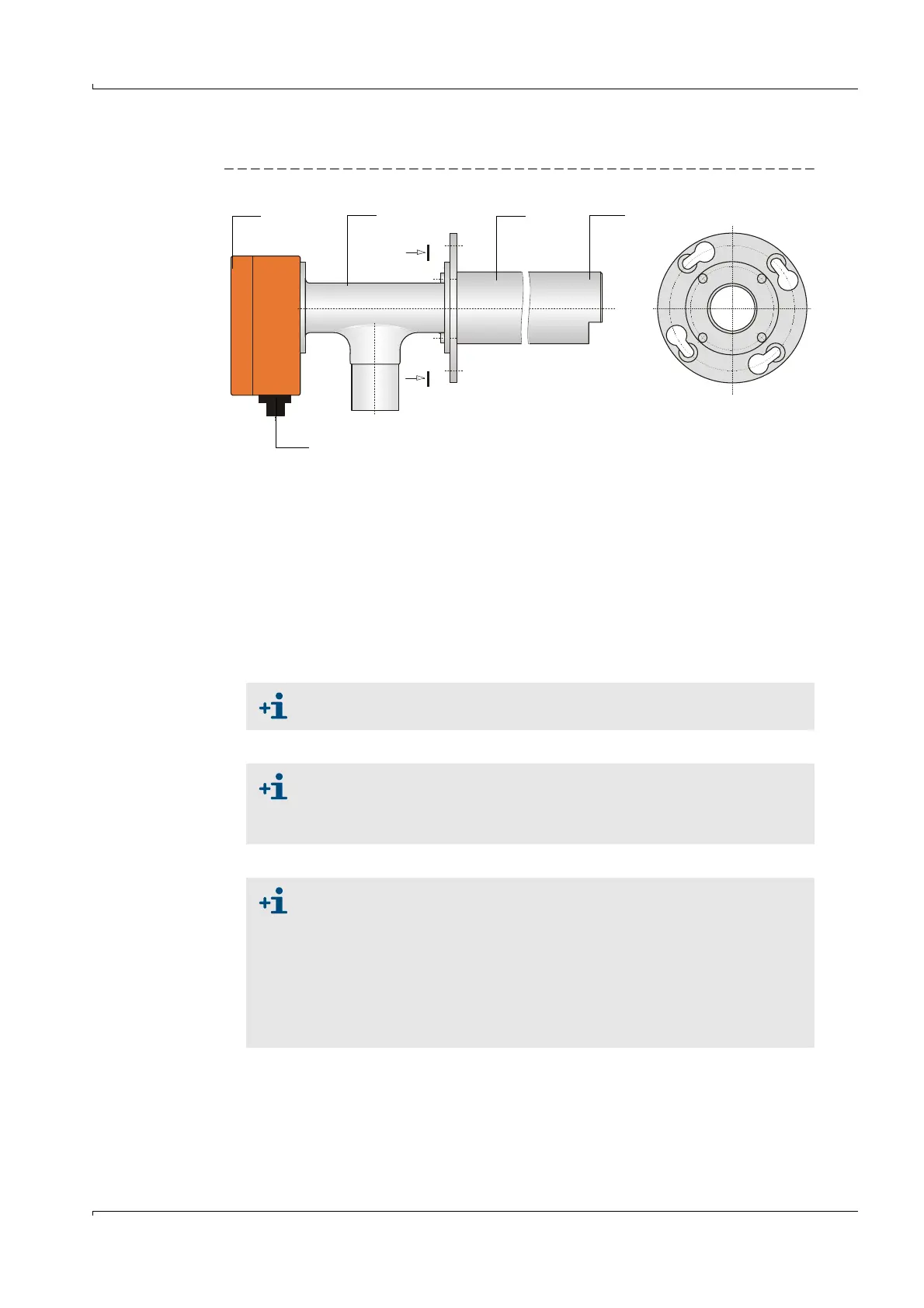

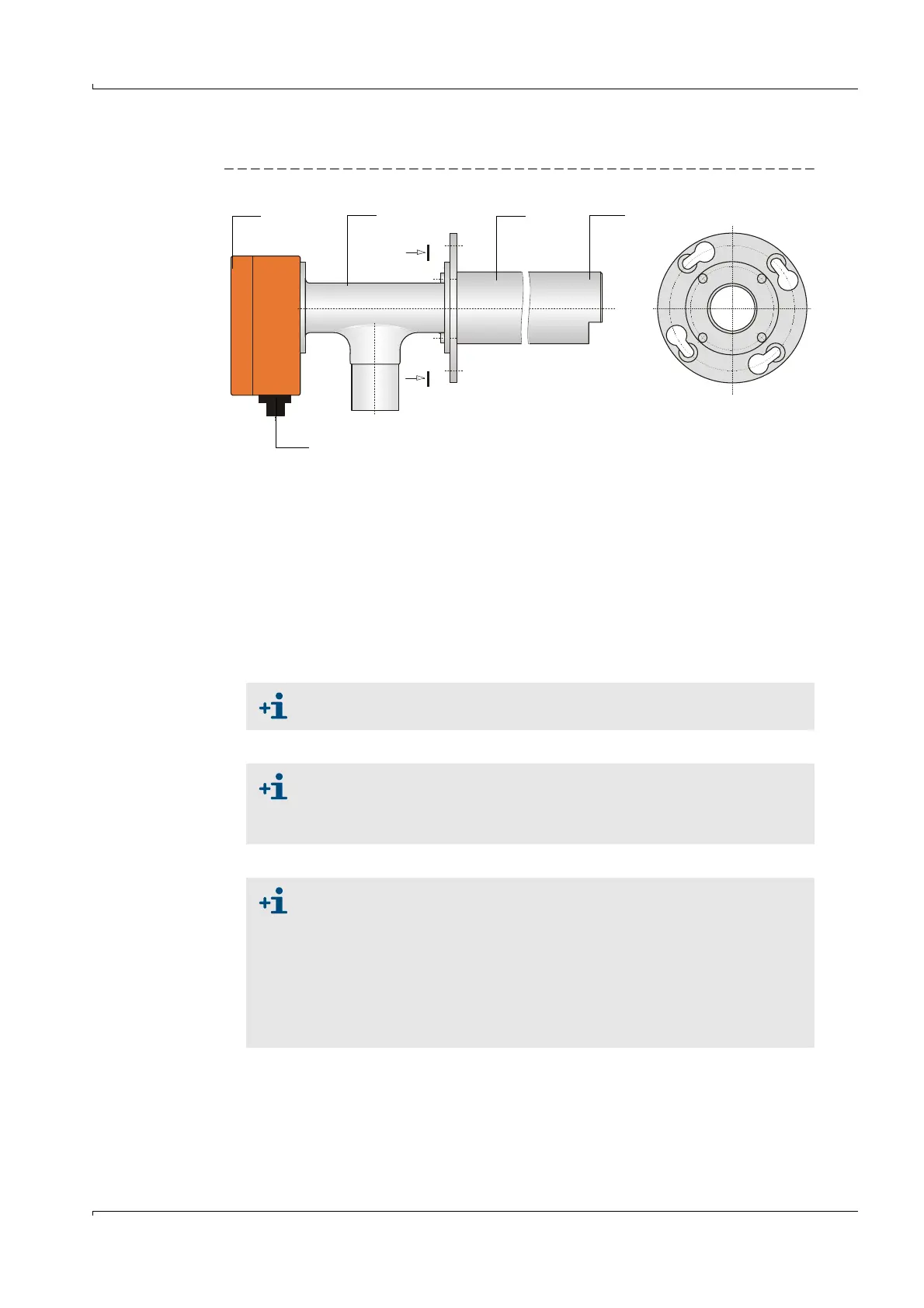

Fig. 13 FLSE100-PM, PH, PHS

These sender/receiver units are intended only for use with wet and sticky dust when the

transducer surface is in high danger of contamination. Purge air is supplied by a purge air

unit to keep the active transducer surface clean and therefore protect against

contamination (

p. 43, 2.3.9). The purge air flow is optimized to maximize the directivity of

the ultrasound beam.

An integrated temperature sensor records the transducer temperature which can then be

displayed in SOPAS ET.

NL = 200 mm (only PM and PH)

350 mm

550 mm

750 mm

NL

A

A

1 Electronics unit 4 Transducer

2 Connection piece 5 Connection for connection cable

3 Duct probe

1

2

4

3

5

A -

See the Application Range Table on page 21 for limitations of use

For dust concentrations > 1 g/m³, install the sender/receiver units at an

angle of 60° to the flow direction (only applicable for FLSE100-PH and

PHS). The downstream sender/receiver unit (B in

p. 15, Fig. 4) has to be

equipped with an impact protector.

At low gas temperatures, the purge air supply can cause the temperature to

drop below the dew point. To minimize the possible corrosion on the probe

head (for example, due to acid formation with corrosive gas compositions),

duct probes with a nominal length greater than that actually required for

the flanges with tube must be selected for temperatures between 150

°C

and 200

°C (for example, if the nominal length of the flange with tube is

350 mm

a duct probe with a nominal length of 550 mm should be

used). The purge air is then heated by the gas temperature in the probe

tube which minimizes temperature drops below the dew point.

Loading...

Loading...