Product Description

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH 13

Subject to change without notice

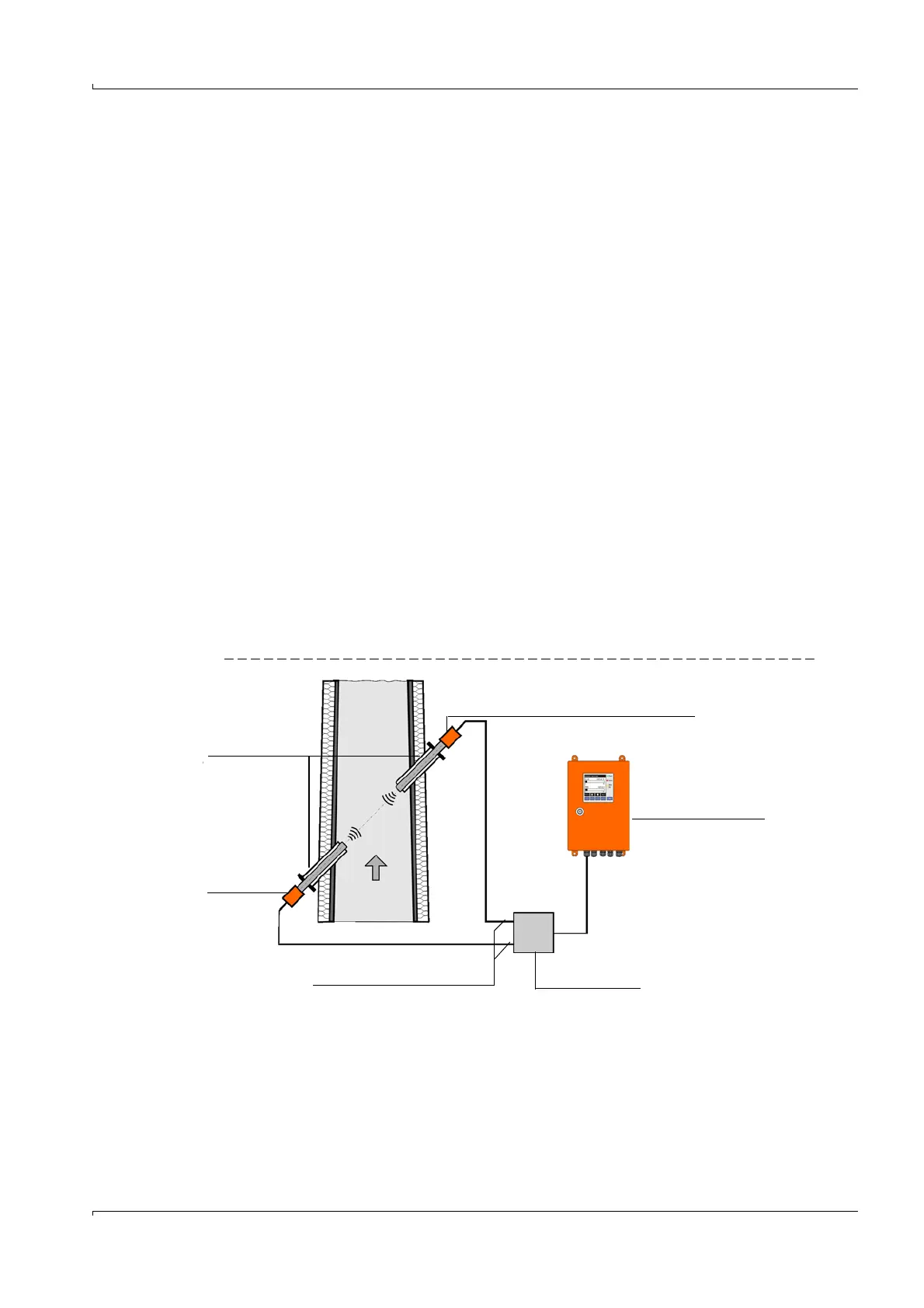

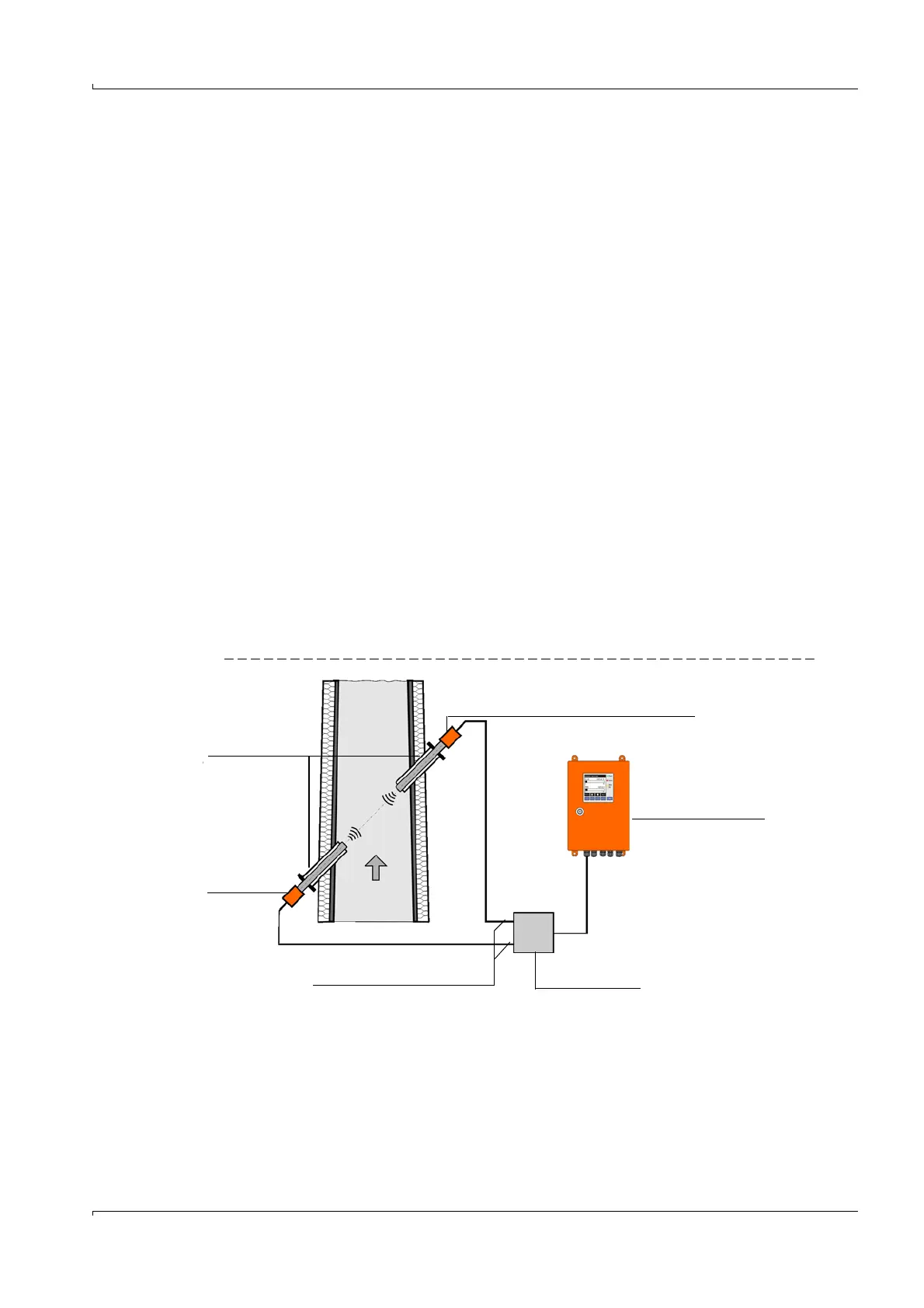

2.2 System overview and functional principle

2.2.1 System overview

The measuring system comprises the following components:

● FLSE100 sender/receiver unit

For transmitting and receiving ultrasonic pulses, signal processing and controlling the

system functions

● Flange with tube

For mounting the sender/receiver units on the gas duct

● MCU control unit

For control, evaluation and output of the data of the sensors connected via RS485

interface

● Connection cables

For signal transmission between the sender/receiver units and control unit

● Junction box for connection cable

For connecting the connection cables

● Purge air unit option

For using purged sender/receiver units to keep the ultrasonic transducers clean and

cool at high gas temperatures

● Cool air unit option

For using internal cooled sender/receiver units to keep the ultrasonic transducers cool

at high gas temperatures

● Measuring tube option

Tube piece with flanges, preassembled for installation in an existing pipeline; with

flanges with tube to fit the sender/receiver units

Fig. 1 FLOWSIC100 system components

● Cooling air control option for device types M-AC and H-AC

Used to control the cooling air supply for sender/receiver units with internal cooling by

switching the cooling air blower on and off automatically depending on the transducer

temperature.

● Emergency air supply option for sender/receiver units with internal cooling (FLSE100-

MAC and HAC)

Set for connecting and operating a temporary emergency air supply of instrument air (to

be provided by customer) for sender/receiver units with internal cooling.

● Emergency air supply option for externally purged sender/receiver units (FLSE100-PM,

PH, PH-S)

Sender/receiver unit

FLSE100 Slave (B)

Duct

MCU control unit

Connection cable

Junction box

Sender/receiver

unit FLSE100

Master (A)

Flange with tube

Loading...

Loading...