22 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Product Description

Subject to change without notice

Duct probe configuration options

2.3.1.1 Standard sender/receiver units

A special transducer design makes it possible to use these sender/receiver units without

cooling by external purge air even with higher gas temperatures. A purge air unit is

therefore not necessary. The advantages are:

● Lower expense for mounting and installation

● Easier maintenance

● Lower operating costs.

For these reasons, standard sender/receiver units should be used where possible.

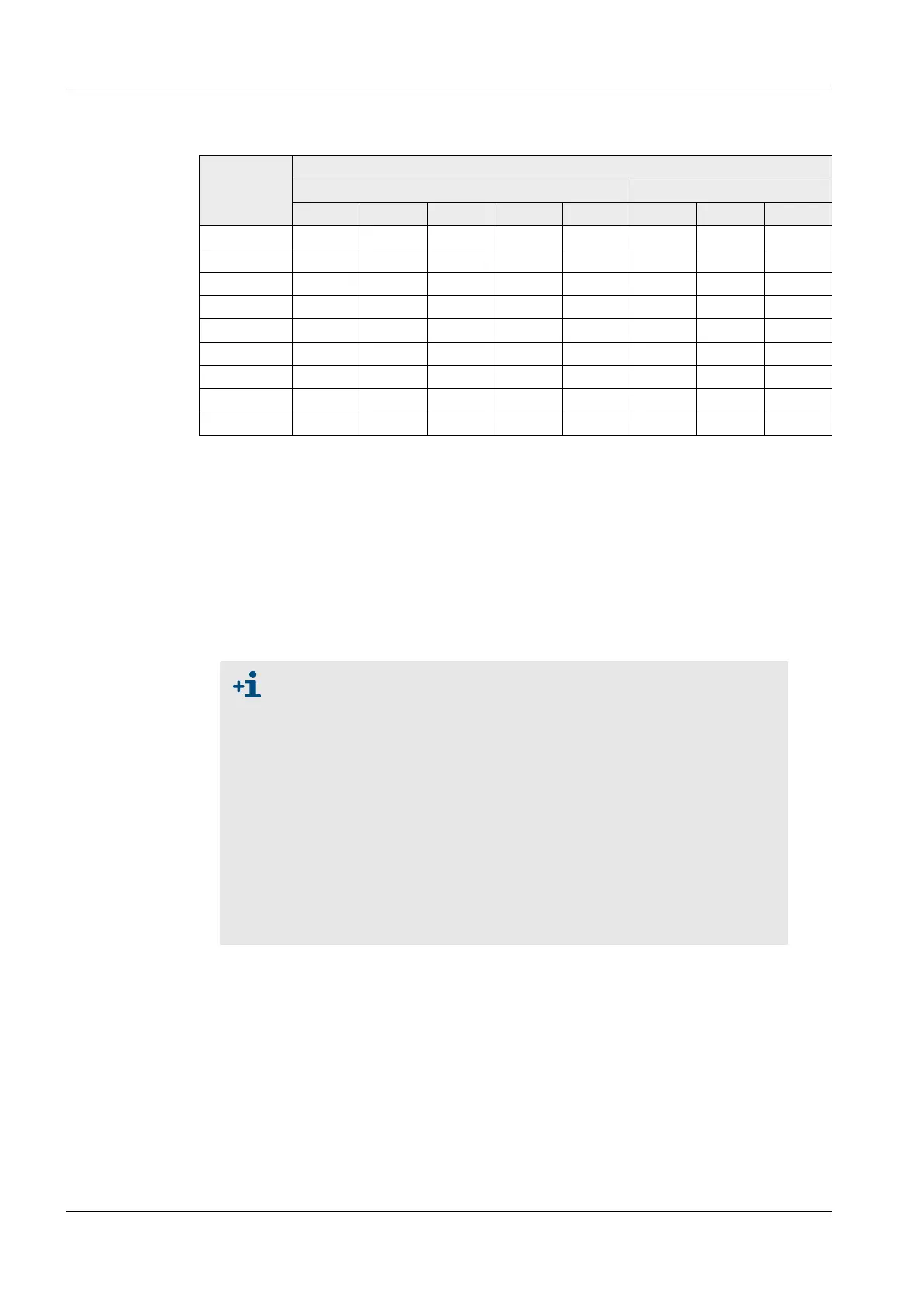

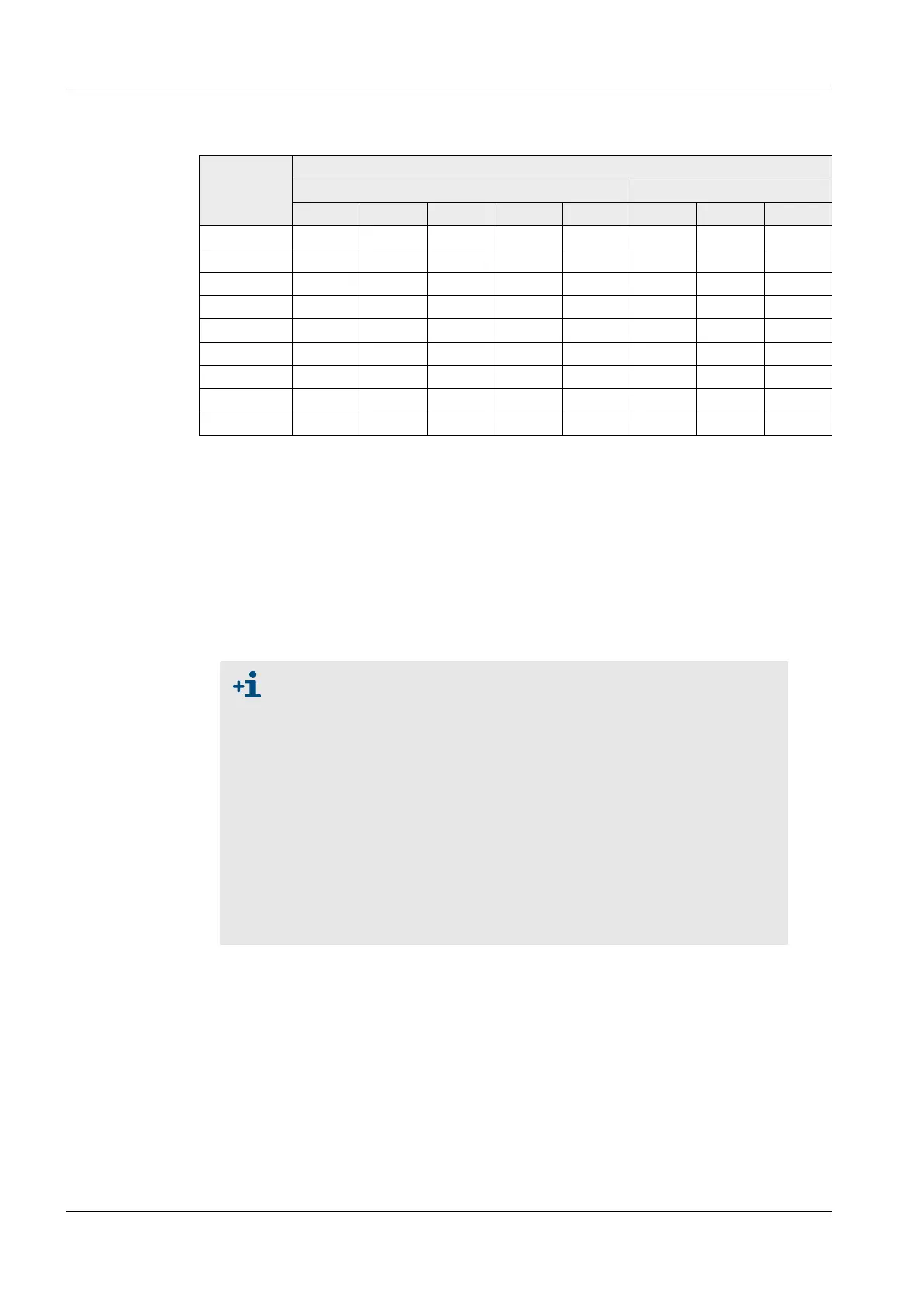

Type FLSE100

Duct probe

Nominal length in mm Material

125 200 350 550 750 SS TI HS

M xxx xxx

H xxxxxxx

PR xxxxx

SA/SD xxx x

MAC x x x x

HAC x x x x

PM xxxxx

PH xxxxxx

PHS x x x x

● The types FLSE100-M, H and PR are intended for use with gas

temperatures up to max. 260

°C. The types FLSE100-SA and SD are

intended for use up to 150°C.

● The measuring system FLOWSIC100 S contains one sender/receiver

unit FLSE100-SA and FLSE100-SD and one connection cable between

the sender/receiver units.

● The type FLSE100-SA has no electronics unit. Communication to the

FLSE100-SD as master (which communicates with the MCU control

unit) runs via an analog connection cable (fixed length: 3m). Install one

FLSE100-SA and one FLSE100-SD per sampling point (1-path configu-

ration).

● Fit the sender/receiver units at an angle of 60° to the flow direction for

dust concentrations > 1 g/m³ (only applicable for FLSE100-H, H-AC, PH

and PH-S). The downstream sender/receiver unit (B in

p. 15, Fig. 4) has

to be equipped with an impact protector.

Loading...

Loading...