Start-up and Parameter Settings

FLOWSIC100 · Operating Instructions · 8012513/YSA5/V 2-1/2016-07 · © SICK Engineering GmbH 127

Subject to change without notice

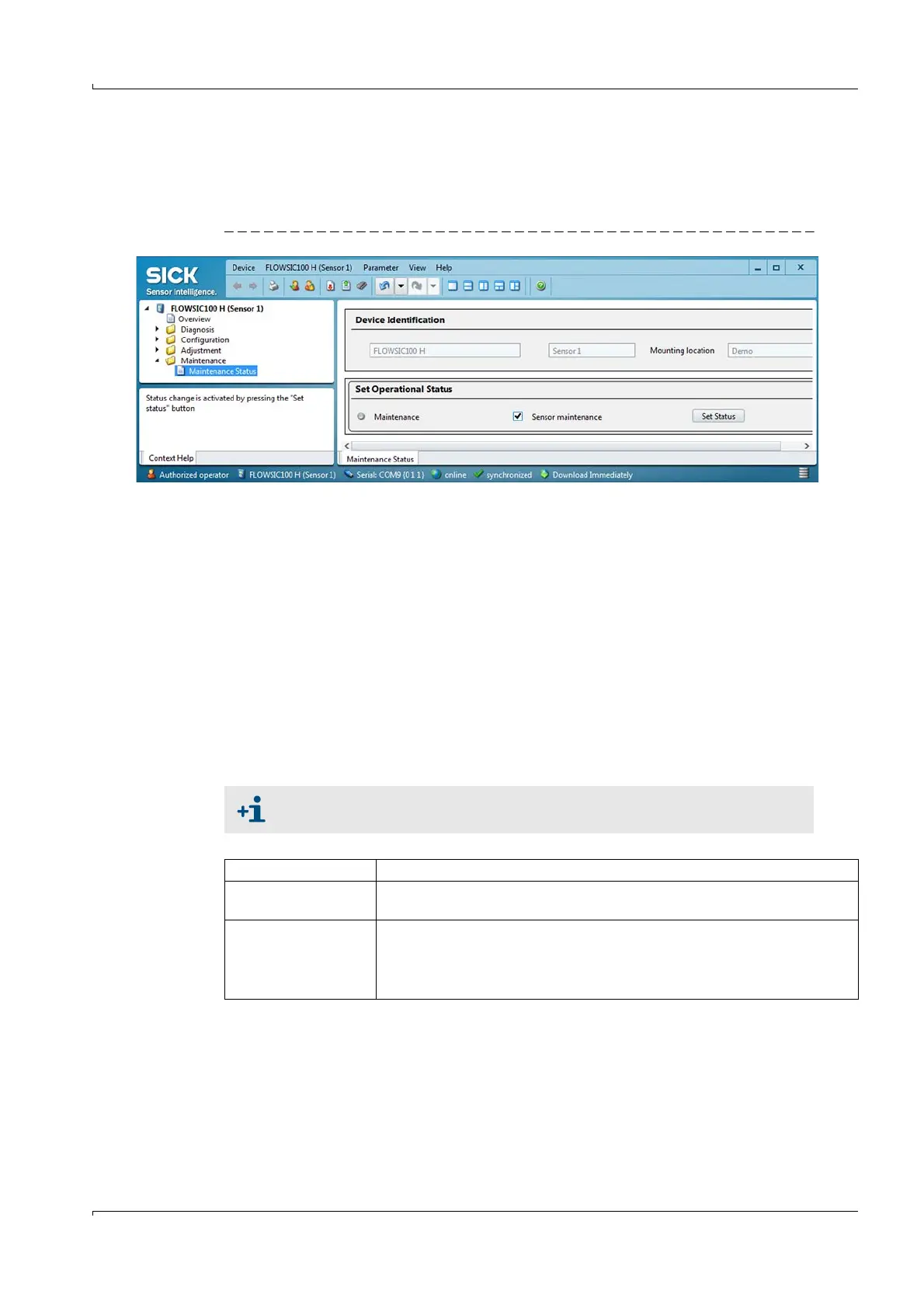

4.2.1 Setting "Maintenance" mode

Open the directory "Maintenance/Maintenance status".

Activate the checkbox "Maintenance" (MCU) or "Sensor maintenance" (sender/receiver

unit) and click "Set Status".

Fig. 100 Switching to Maintenance mode

A control lamp signals the "Maintenance" state as follows:

– In the SOPAS menu "FLOWSIC100 X (Sensor) / Overview",

– In the SOPAS status indicator in the field at the bottom left,

– On the display of the MCU control unit (only for MCU with display option).

4.2.2 Setting the system data parameters on the FLOWSIC100 sensor

Open the device file "FLOWSIC100 X (sensor)" and enter the Level 1 password (

p. 125,

§99).

Set the maintenance mode (

p. 127, §4.2.1).

Basic requirements for every measurement are selecting the unit system (metric or

imperial units) to be used and entering the application parameters (measuring path,

installation angle, cross-sectional area). Select directory "Application Parameters" to enter

settings (

Fig. 101). The settings are uploaded to the FLOWSIC100 after switching from

"Maintenance" to "Measurement".

The following is applicable for application parameters:

The application parameter settings are converted automatically when the unit

system is changed.

Measuring path Distance between the transducers (L in Fig. 102)

Installation angle Angle between the measuring axis and main direction of the gas flow ( in

Fig. 102)

Cross-sectional area

(required to calculate

the volume flow)

Area in range of the ultrasonic transducer that is vertical to the flow direction and

enclosed in the inner duct walls.

If the cross-sectional area changes in the vicinity of the measurement setup,

enter the mean value of the areas between the sender/receiver units A and B.

Loading...

Loading...