50 FLOWSIC100 · Operating Instructions · 8012513/YSA5/V2-1/2016-07 · © SICK Engineering GmbH

Assembly and Installation

Subject to change without notice

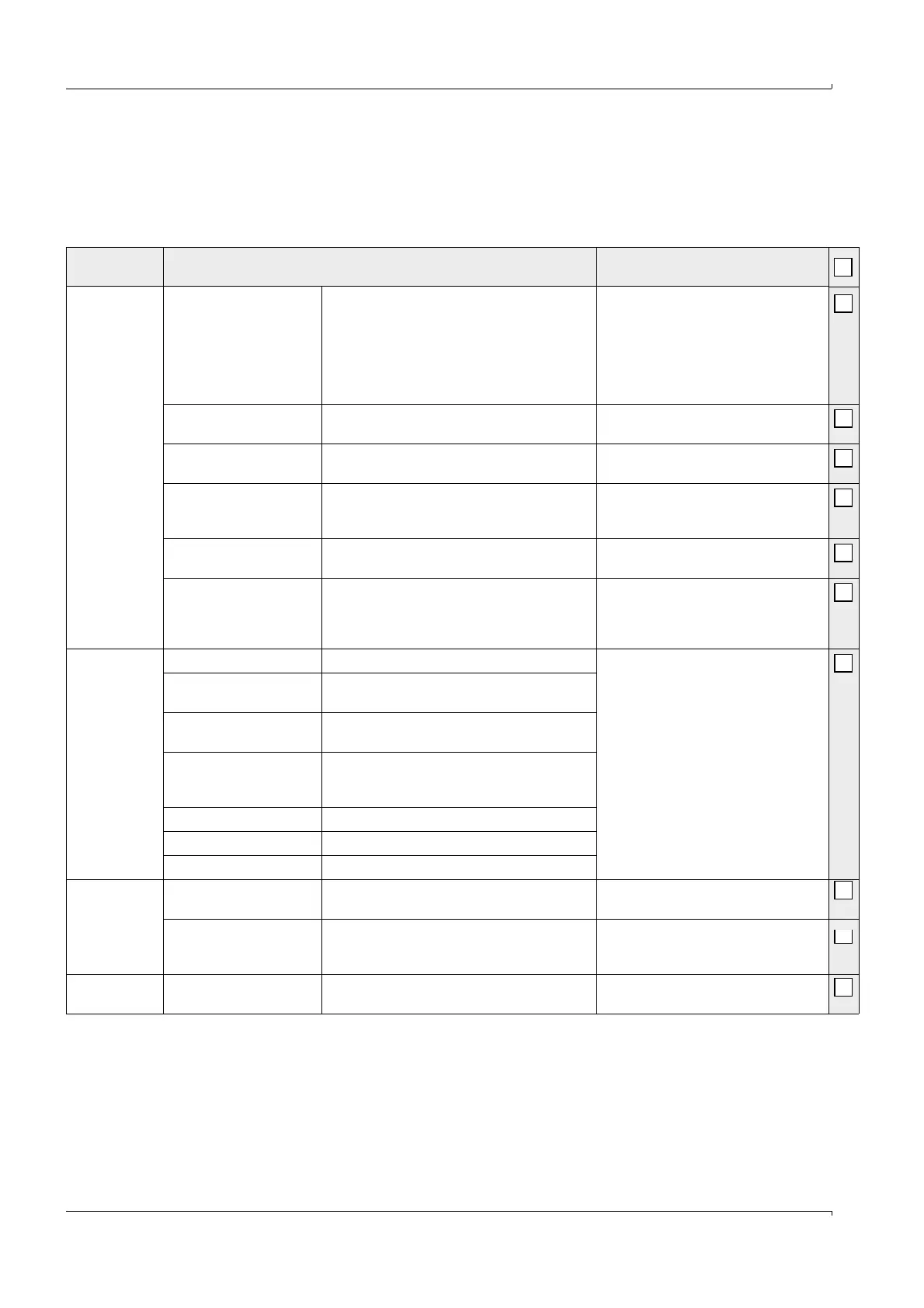

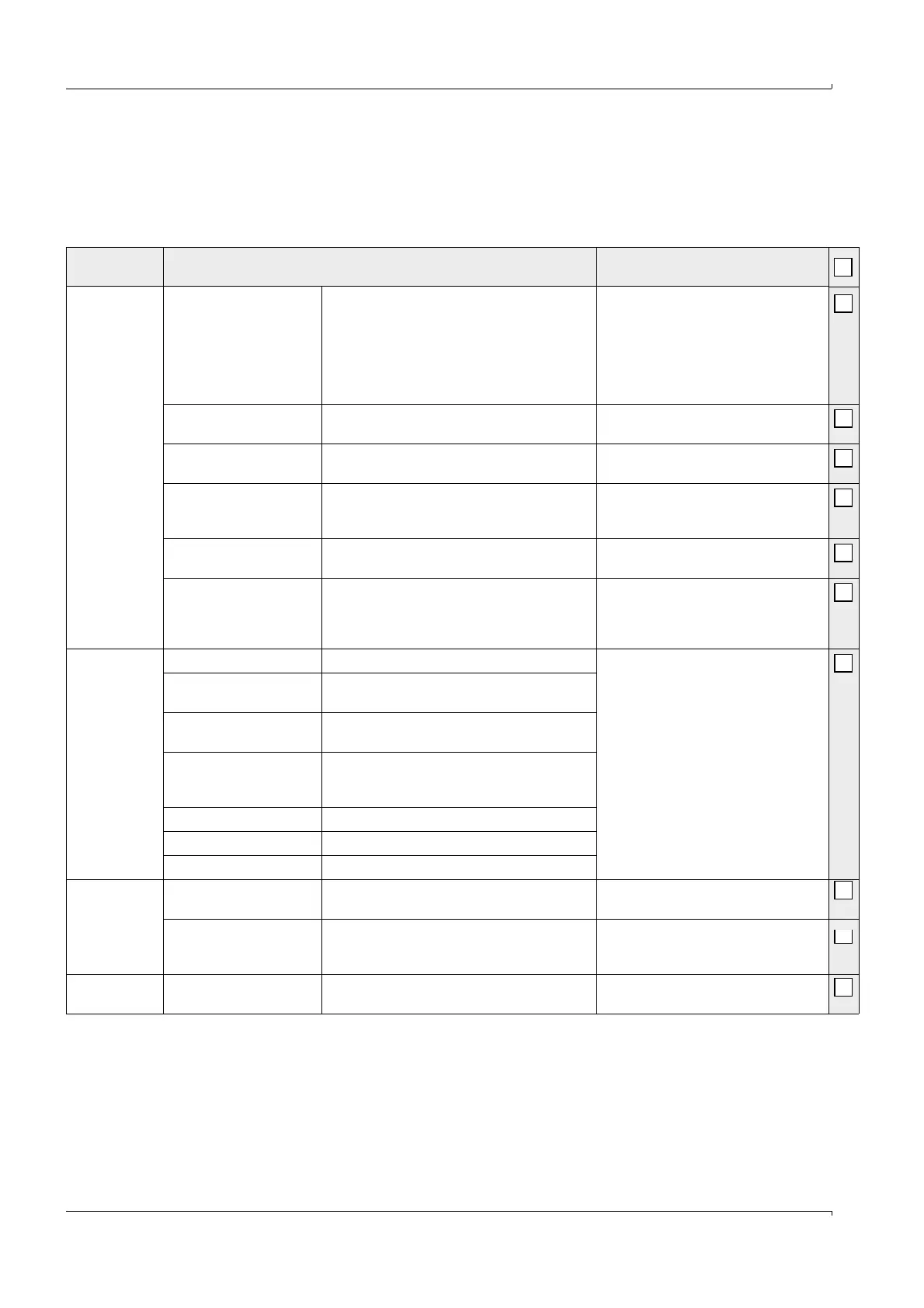

3.1 Project planning

The following Table provides an overview of the project planning work to be carried out to

ensure the device is correctly installed and fully functional. You can use this Table as a

checklist by ticking off all the steps you have carried out.

Task Requirements Work step

Determine the

measuring and

installation

locations for the

device compo-

nents (

p. 51,

3.1.1)

Inlet and outlet sections

must be of sufficient length

Homogeneous flow distri-

bution

If possible, no bends, cross-section variations,

feed pipes, discharge pipes, flaps, or fittings

in the inlet and outlet sections

Comply with specifications for new

installations; choose the best possible

location for existing installations; if

necessary, determine flow profile in

accordance with DIN EN 132841;

if inlet/outlet sections are too short: Inlet

section > outlet section.

Accessibility, accident

prevention

Device components must be easily and safely

accessible

Provide platforms or pedestals when

necessary

Vibration-free installation Accelerations < 1 g Take appropriate measures

to eliminate/reduce vibrations

Ambient conditions Limit values in accordance with Technical Data If necessary:

Fit weatherproof covers/sun protection

Cover or insulate device components.

Purge air supply (for purged

FLSE100 only)

Clean intake air (as little dust as possible,

no oil, humidity, corrosive gases)

Choose the best possible intake location

Instrument air (only for

optional emergency air sets

for purged/cooled device

types)

Free from oil, dust and grease Choose the best possible installation

location

Choose the

device

components

Internal duct diameter Type of sender/receiver unit Choose components according to the

Configuration Table and information in

p. 17, 2.3.

If necessary, plan additional measures

to install the flange with tube

(

p. 60, 3.2.1).

Duct wall strength with

insulation

Nominal length of sender/receiver unit, flange

with tube

Internal duct pressure Type of sender/receiver unit; purge air unit

version (for purged FLSE100)

Gas temperature Type of sender/receiver unit (standard or inter-

nally cooled)

Purge air supply for purged FLSE100

Dust concentration Type of sender/receiver unit

Gas composition Material of duct probe and transducer

Installation locations Cable and purge air hose lengths

Plan the

calibration

openings

Accessibility Easy and safe Provide platforms or pedestals when

necessary

Distances to the measure-

ment level

No mutual interference

between calibration probe and FLOWSIC100

Ensure sufficient distance between the

measurement and calibration level

(approx. 500 mm)

Plan the voltage

supply

Operating voltage, power

requirements

In accordance with Technical Data in

p. 166,

6.1

Ensure sufficient cable cross-sections

and fuse

Loading...

Loading...