Troubleshooting

FLOWSIC600 · Technical Information · 8010125 V 4.0 · © SICK AG 193

Subject to change without notice

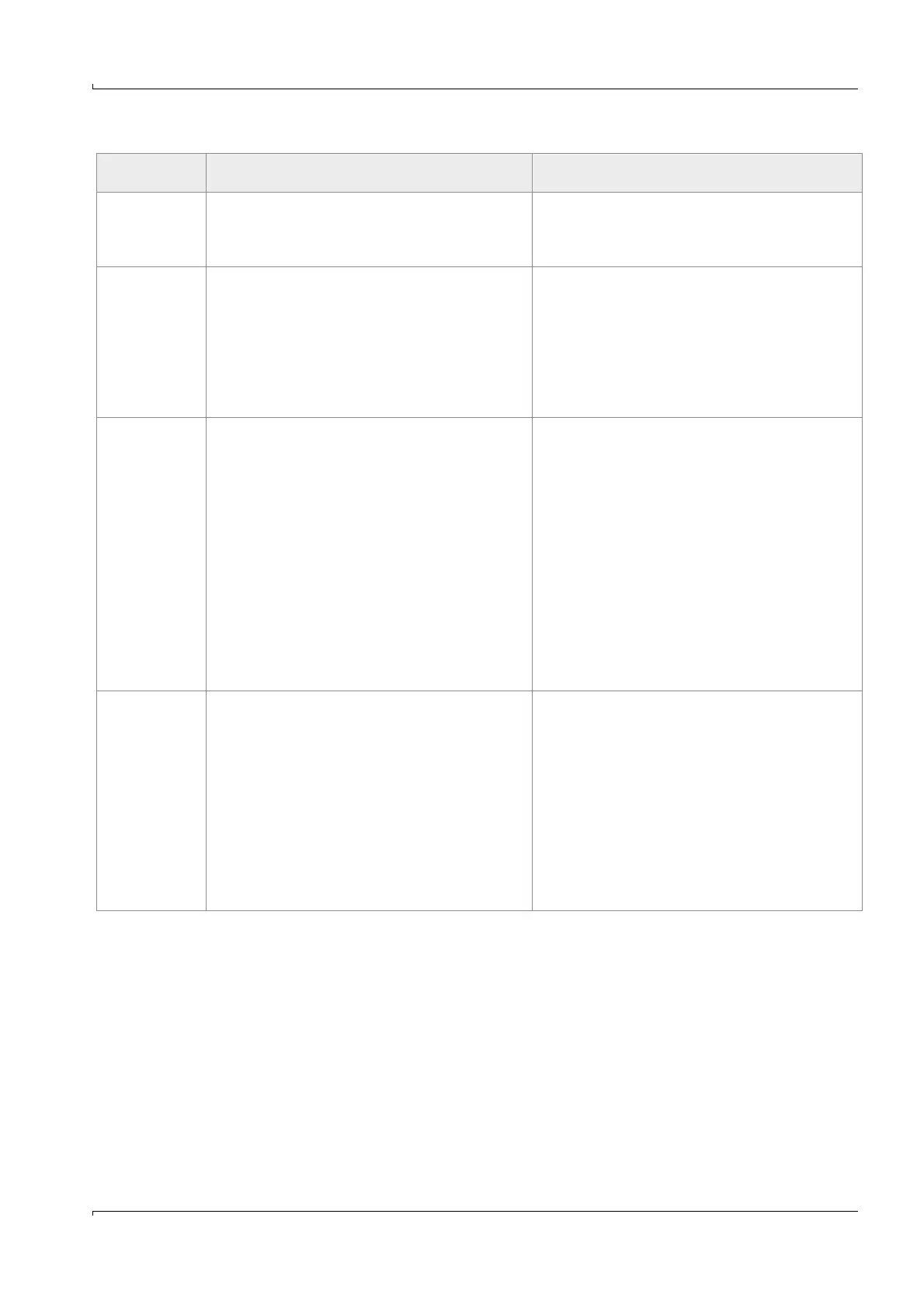

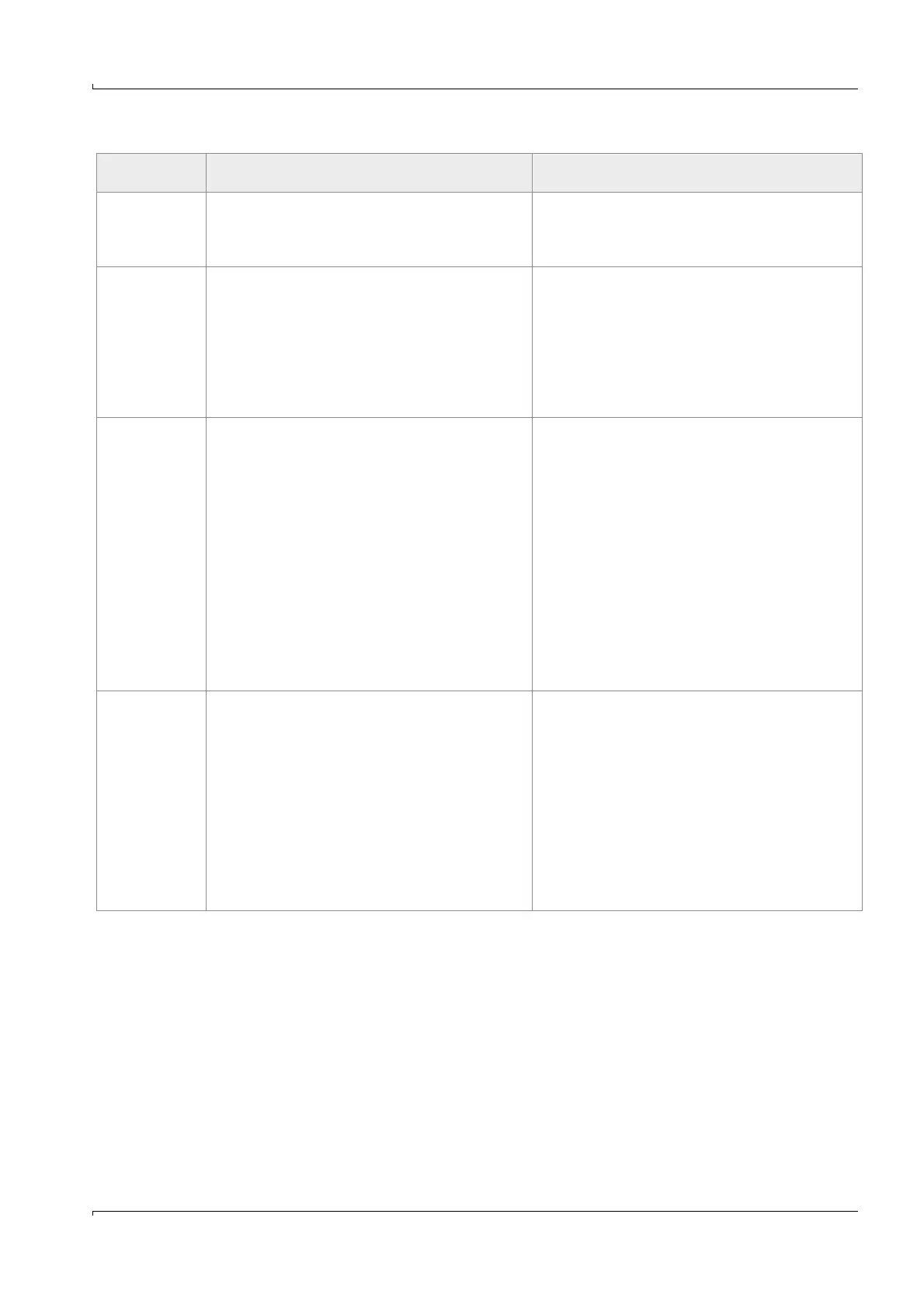

Interpretation of active User Warning status (continued)

Yellow light

for...

Possible causes Actions

Battery

lifespan

(change

battery)

The remaining battery lifespan is less than 15%

Check when the battery was last replaced.

Replace battery within one year (battery age

is 8.5 years)

Path

turbulence

1

A change in the path turbulence indicates

changed flow conditions (e.g. a blocked flow

conditioner).

Compare the current value with previous

measurements (e.g. Maintenance Report

from commissioning) and compare the

conditions.

Check whether the User Warning limit is

configured correctly (

pg. 149, 5.7.1).

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained staff.

SNR limit

(Signal-to-

noise ratio)

Interfering noise caused by fittings in the

pipeline, valves that are not fully open, sources

of noise near the measuring location, or

defective ultrasonic transducers may affect the

signal-to-noise-ratio. Other possible sources of

interference include electrical noise caused by

bad contact of the connectors or sources of

acoustic interference, such as control valves or

very high flow velocities.

These values are generally site-specific and do

not change as long as the conditions remain the

same. A reduction in the signal-to-noise ratio

while the AGC level stays unchanged, hints at

sources of acoustic interference (e.g. pressure

regulator) near the point of measurement.

Compare the current value with previous

measurements (e.g. Maintenance Report

from commissioning) and check whether the

User Warning limit is configured correctly

(

pg. 149, 5.7.1).

Check the AGC level.

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained staff.

AGC limit

(signal

amplification)

The signal amplification (AGC level) set by the

meter largely depends on the current process

pressure. The reception sensitivity is inversely

proportional to the process pressure: if the

pressure doubles, the sensitivity will be 6dB

smaller.

Under normal conditions, this value is very

stable over time. Significant fluctuations in the

AGC level indicate a low-quality received signal.

A significant increase under comparable process

conditions is usually caused by dirt on the

ultrasonic transducers.

Compare the current value with previous

measurements (e.g. Maintenance Report

from commissioning) and check whether the

User Warning limit is configured correctly

(

pg. 149, 5.7.1).

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained staff.

1

These User Warning limits are only monitored, as long as certain preconditions are met (

pg. 154, Table 22).

Loading...

Loading...