196 FLOWSIC600 · Technical Information · 8010125 V 4.0 · © SICK AG

Troubleshooting

Subject to change without notice

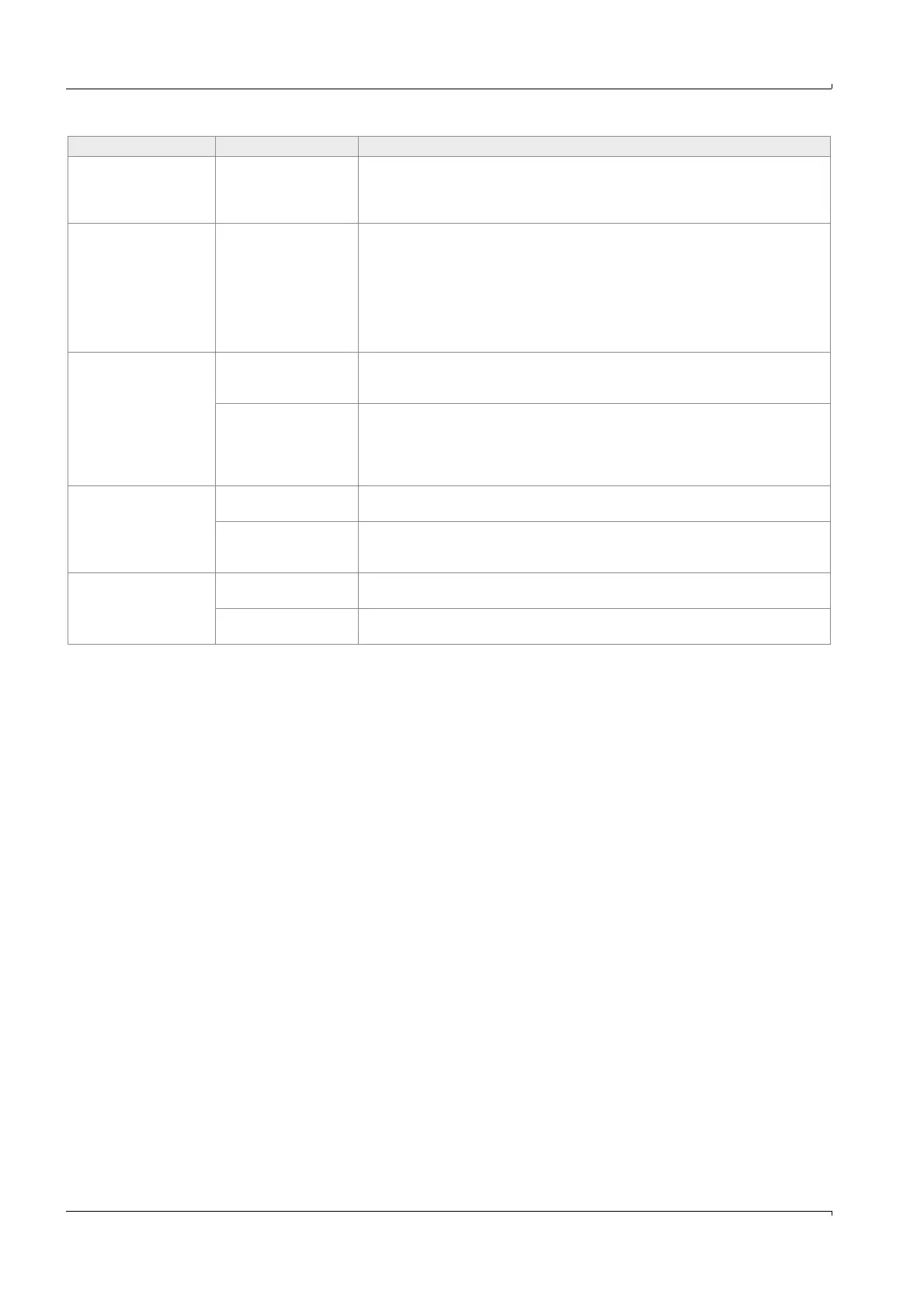

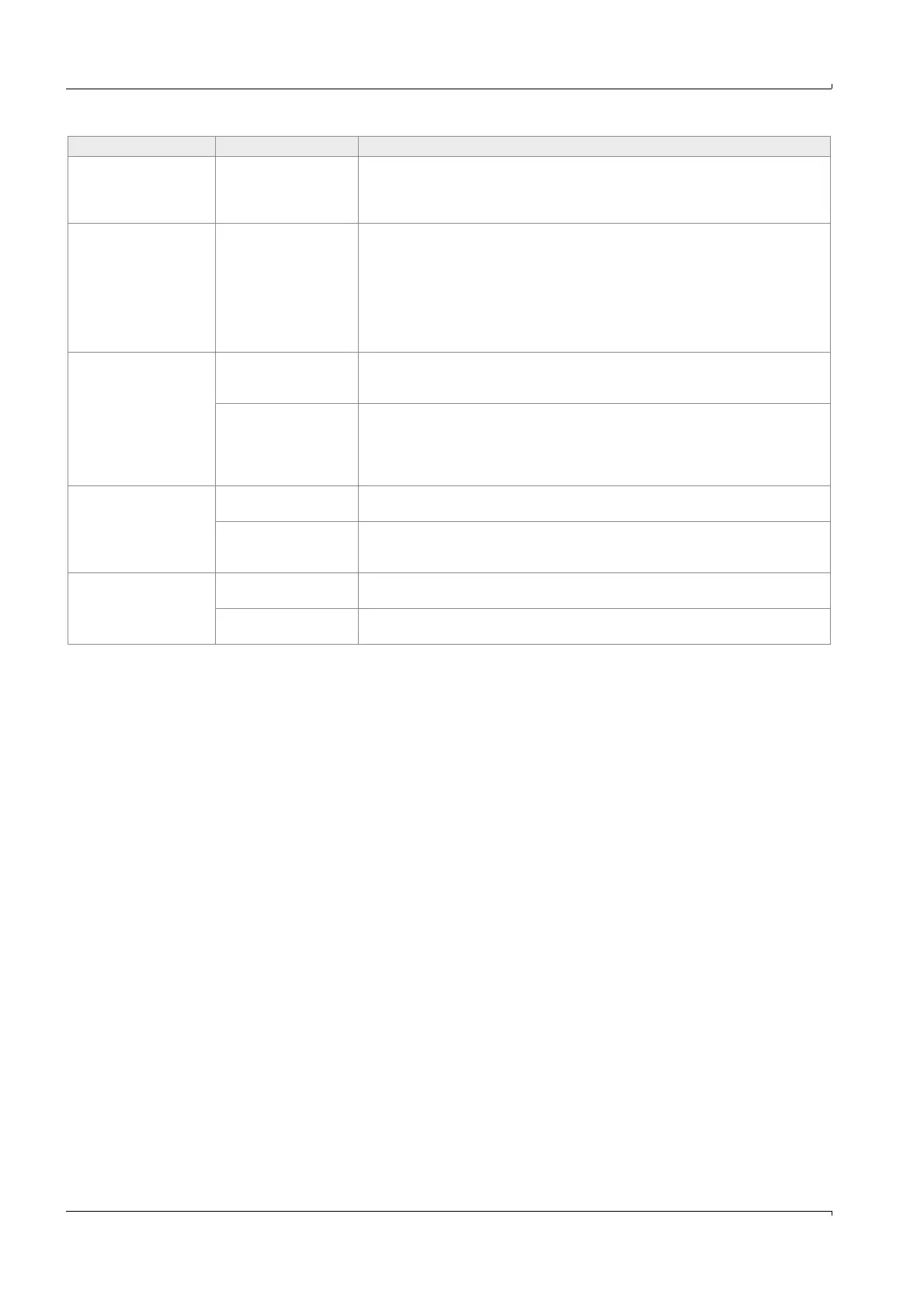

Problem Possible causes Actions

Implausible sepeed of

sound

Gas composition,

pressure or temperature

measurement is

incorrect

Check gas composition, pressure and temperature.

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained

staff or your local SICK representative.

Different speed of sound

in the individual paths

Faulty transducer or

electronic module

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained

staff or your local SICK representative.

Trained staff: Replace the transducer(s) (see Service Manual, Chapter 7).

Note:

Temperature-induced stratification can result in differences between the individual

paths, especially with very low flow (higher temperatures generate higher speeds of

sound). Even if the plant is being filled or if it is shut down, different speeds of sound

may occur in the individual paths as a result of stratification.

Lower signal-to-noise

ratio and reception sen-

sitivity

Increased number of

rejected measurements

in individual paths

Damaged transducer Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained

staff or your local SICK representative.

Trained staff: Replace the transducer(s) (see Service Manual, Chapter 7).

Additional sources of

noise due to a valve that

is not fully open, fit-

tings, noise sources

near the device

Check the measurement plausibility and number of rejected measurements and, if

necessary, eliminate noise sources.

Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained

staff or your local SICK representative.

Increased receiver sensi-

tivity (AGC)

Different gas composi-

tion or process pressure

No action required on the device

Transducer(s) are dirty Create a Diagnosis Session according to

pg. 198, 7.3 and contact your trained

staff or your local SICK representative.

Trained staff: Clean the transducer(s) (see Service Manual, Chapter 7)

Increased number of

rejected measurements

in all paths

Additional noise

sources

Eliminate noise sources

Gas velocity outside the

measuring range

Loading...

Loading...