Chapter 5 Operating instructions

S300

58 © SICK AG • Industrial Safety Systems • Germany • All rights reserved 8010948/YY96/2016-02-17

Subject to change without notice

Mounting

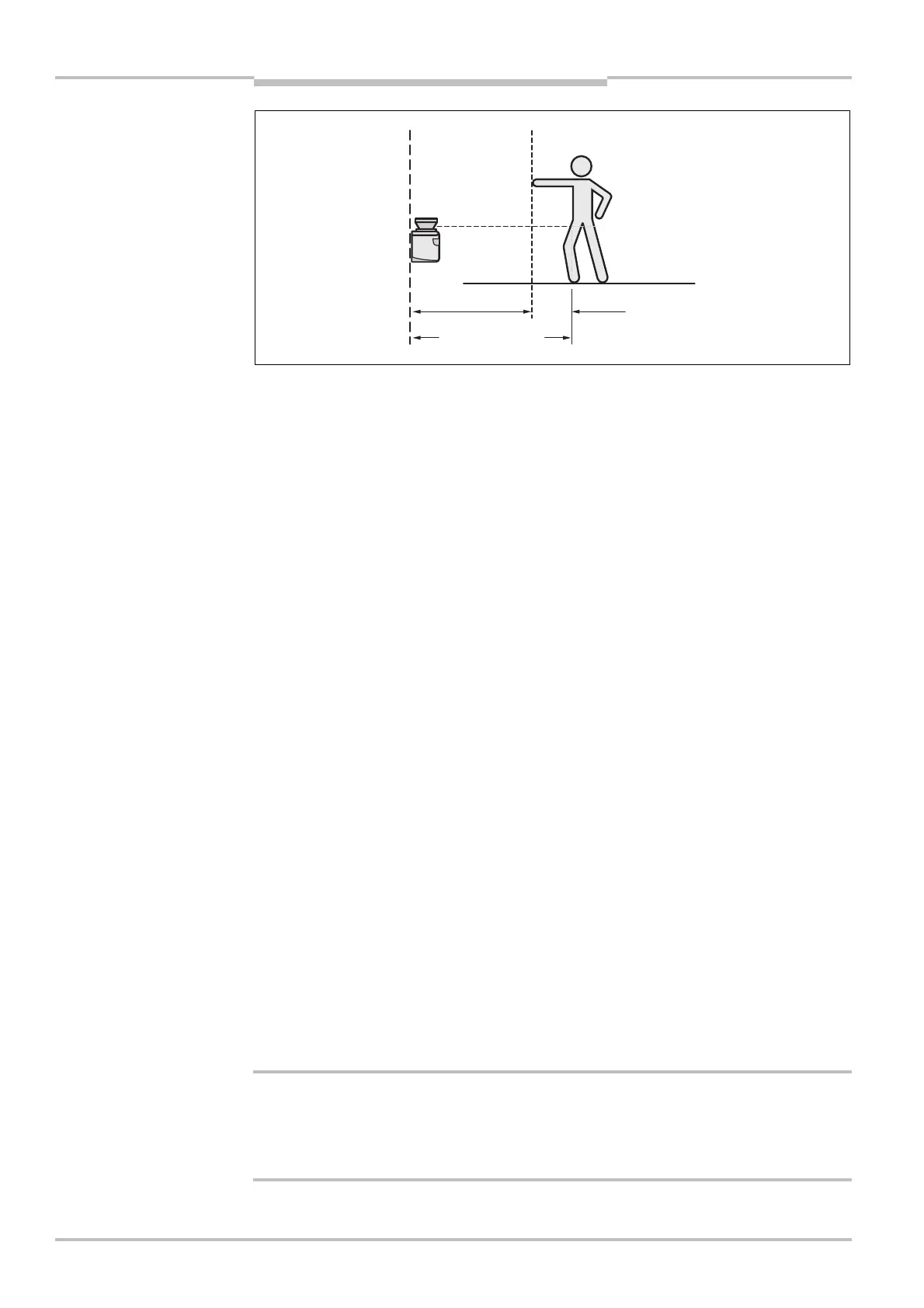

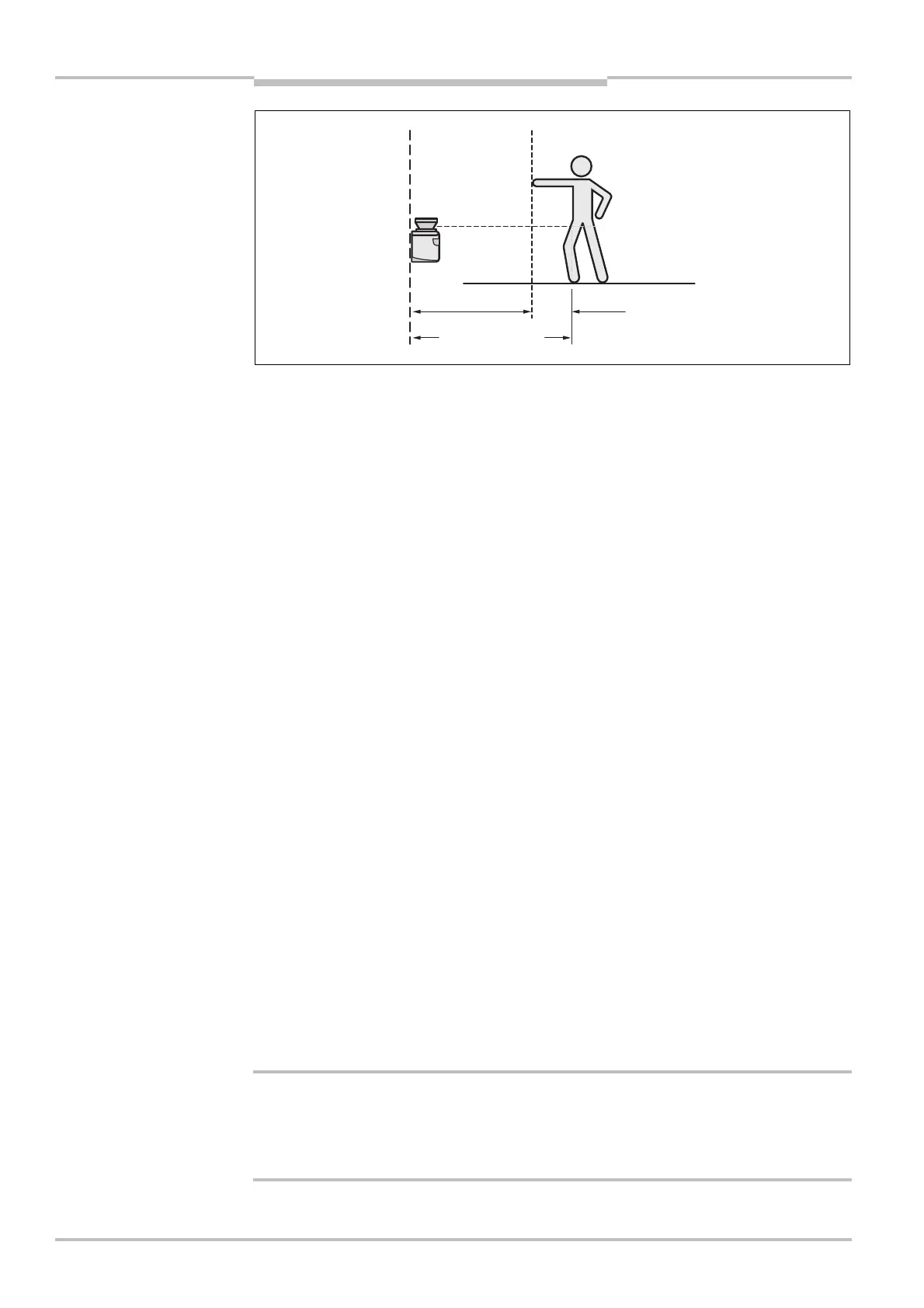

The minimum distance S depends on:

approach speed of the body or parts of the body

stopping/run-down time of the machine or system

(The stopping/run-down time is shown in the machine documentation or must be

determined by taking a measurement.)

response time of the S300

supplements for general measurement errors and any measurement errors related to

reflection

supplement for prevention of reaching over

height of the scan plane

possibly the time for switching between the monitoring cases

How to calculate the minimum distance S (see EN ISO 13855):

First, calculate S using the following formula:

S = (K × (T

M

+ T

S

)) + Z

G

+ Z

R

+ C

Where …

K = Approach speed (1600 mm/s, defined in EN ISO 13855)

T

M

= Stopping/run-down time of the machine or system

T

S

= Response time of the S300 and the downstream controller

Z

G

= General safety supplement of the S300 = 100 mm

Z

R

= Supplement for measurement error related to reflection

C = Supplement for prevention of reaching over

Response time T

S

of the S300

The response time T

S

of the S300 depends on …

the basic response time of the S300,

the multiple sampling set,

the transmission speed to external OSSDs via EFI.

See section 12.2 “OSSD response times” on page 117.

Supplement Z

R

for measurement errors caused by reflection

Avoid mounting retroreflectors at a distance of less than one meter from the boundary

of the protective field!

With retroreflectors positioned at a distance of less than 1 m from the boundary of the

protective field a supplement, Z

R

, of 200 mm must be added to the protective field.

WARNING

G

R

M

S

Loading...

Loading...