Programming and Operating Manual (Milling)

120 6FC5398-4DP10-0BA1, 01/2014

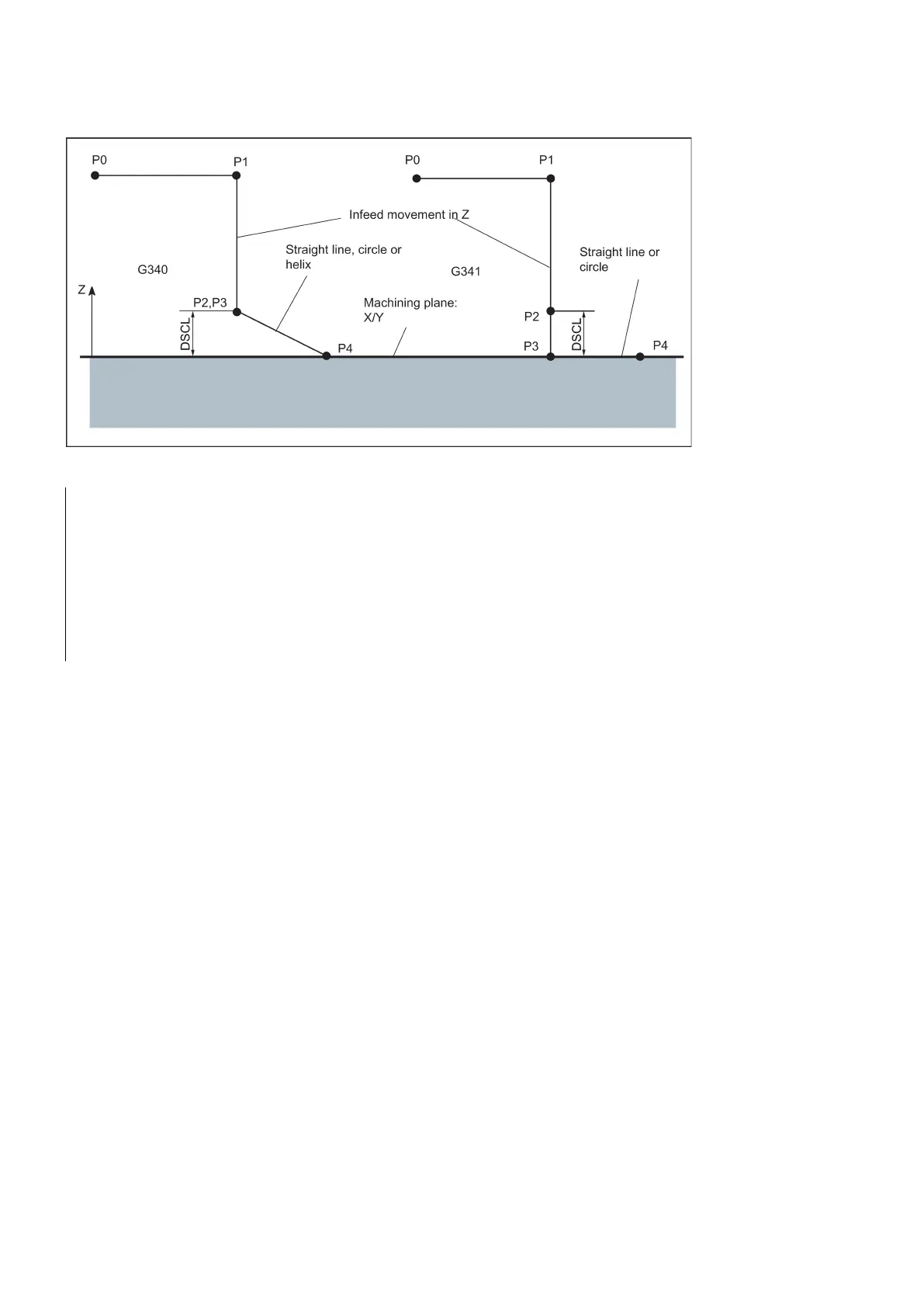

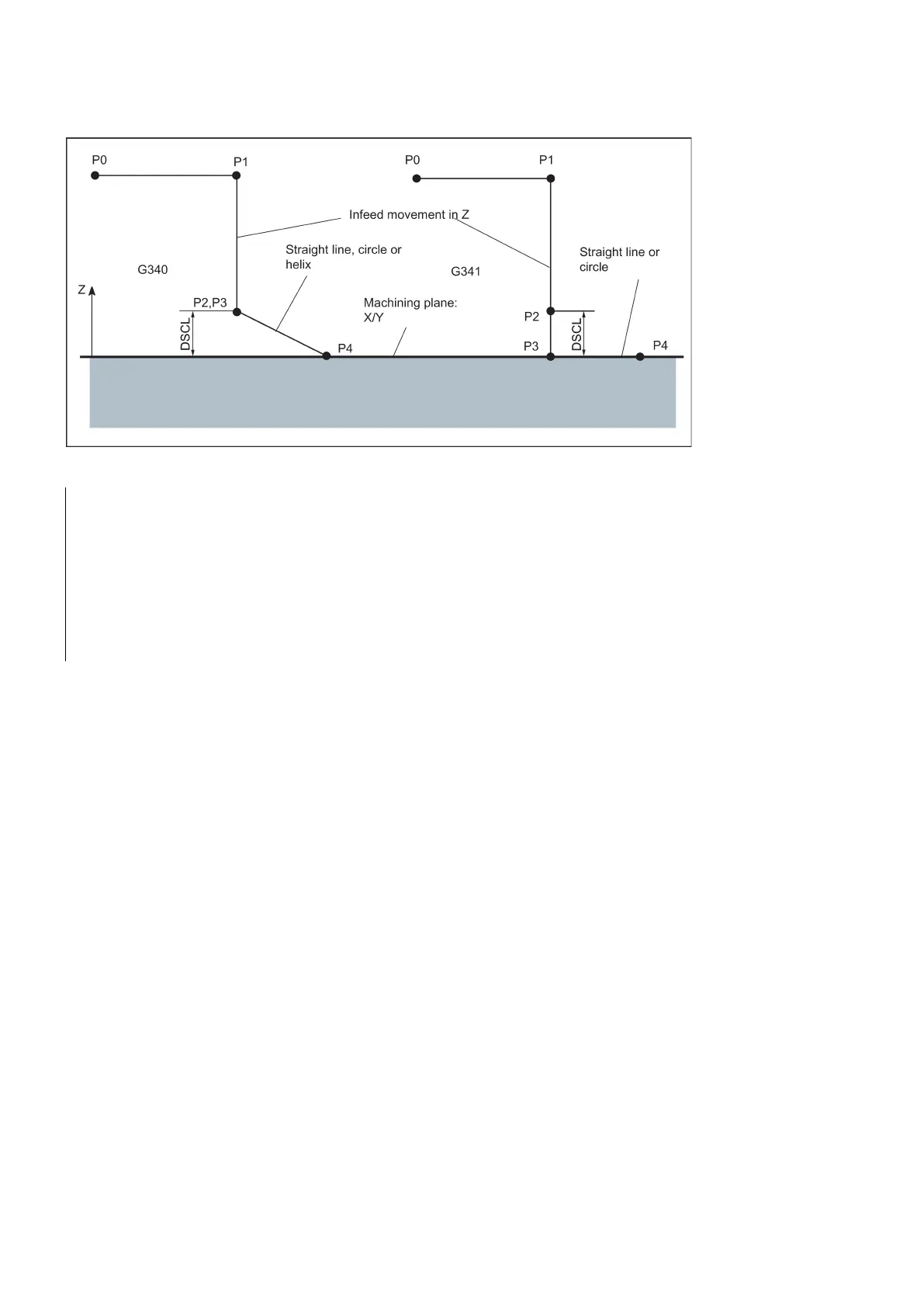

See the following sequence of the approach motion dependent on G340/G341 (example with G17):

Programming example: Approach along a semi-circle with infeed

; Activate tool, X/Y plane

N30 G41 G347 G340 DISCL=3 DISR=13 Z=0 F500

; Approach along a semi-circle with radius: 13 mm,

; Safety clearance to the plane: 3 mm

alternatively N30/N40:

N30 G41 G347 G340 DISCL=3 DISR=13 X40 Y-10 Z0 F500

or

N30 G41 G347 G340 DISCL=3 DISR=13 F500

N40 G1 X40 Y-10 Z0

Explanation with regard to N30/N40:

By using G0 (from N20), the point P1 (starting point of the semi-circle, corrected by the tool radius) is approached in the

plane Z=30, then lowering to the depth (P2, P3) with Z=3 (DISCL). The contour is reached at point X40 Y-10 in the depth

Z=0 (P4) along a helix curve at a feedrate of 500 mm/min.

Approach and retraction velocities

● Velocity of the previous block (e.g. G0):

All motions from P0 up to P2 are executed at this speed, i.e. the motion parallel to the machining plane and the part of

the infeed motion up to the safety clearance DISCL.

● Programmed feedrate F:

This feedrate is active from P3 or P2 if FAD is not programmed. If no F word is programmed in the SAR block, the

velocity of the previous block will act.

● Programming using FAD:

Specify the feedrate for

– G341: Infeed motion vertically to the machining plane from P2 to P3

– G340: from point P2 or P3 to P4

If FAD is not programmed, this part of the contour is traversed at the speed which is active modally from the

preceding block, in the event that no F command defining the speed is programmed in the SAR block.

Loading...

Loading...