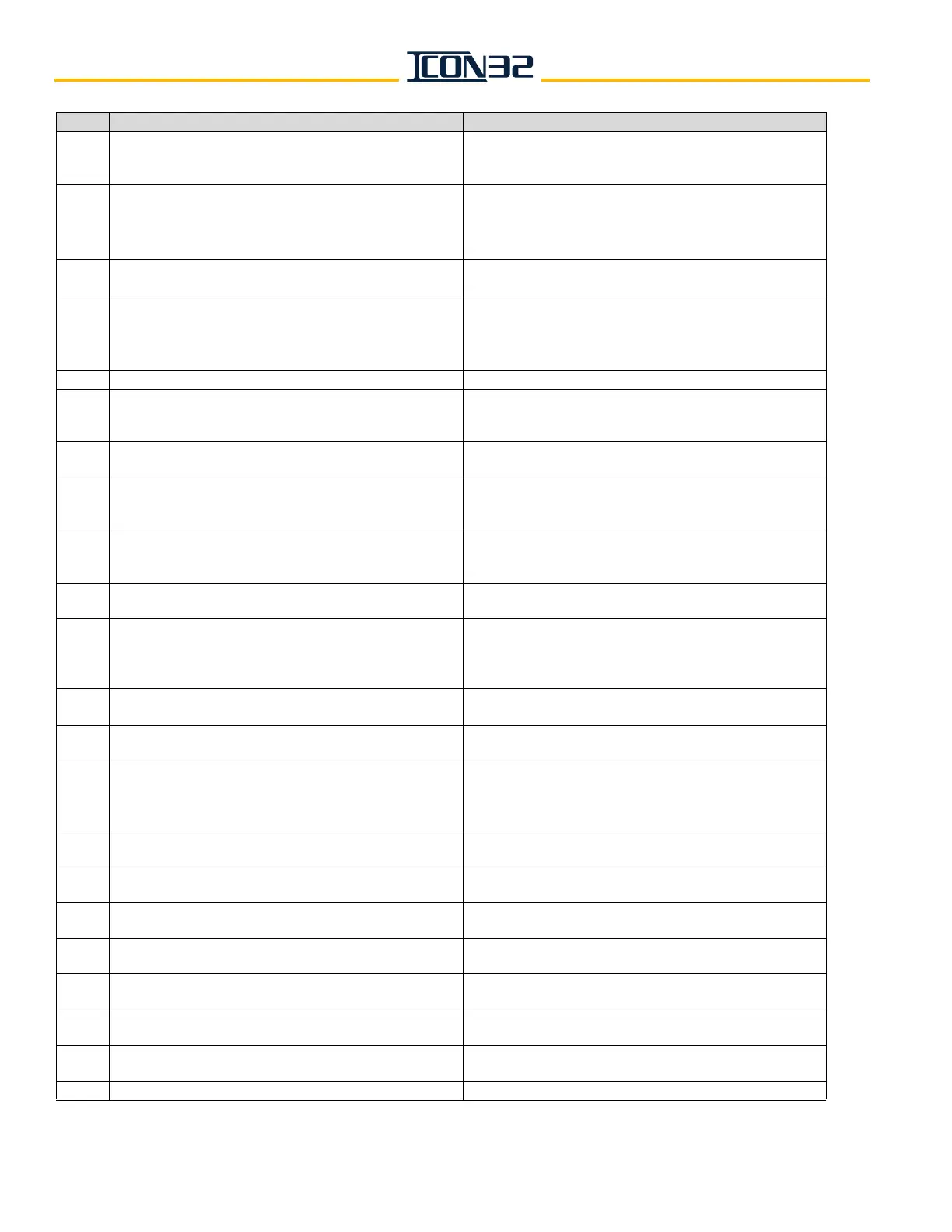

Control System Fault Codes Diagnostics Section

©Vertical Express 3-34 Printed in USA April 2020

This manual shows only the parameters that have an operational relevance to the ICON32. The UIT may have

additional parameters available, which should not effect the controller operation.

1018

Normal limit error - Both of the top and bottom normal limits

(DL, NTST, NTSB) are active at the same time.

• CAN loading incorrect/noise on Car CAN.

• Magnet issue with selector.

• A defective I/O.

1019

• The normal limits and the car position do not agree.

• The selector is not lost.

• The car position is not at the top or bottom floor.

• The I/O DL, NTST, NTSB do not agree.

• CAN loading incorrect/noise on Car CAN.

• Magnet issue with selector.

1020

Software error - The I/O database has been corrupted, or the

checksum for I/O has changed.

—

1021

• A safety node is offline.

• Inspection indicates an invalid I/O condition.

• The status of an I/O indicates a combination of active and

inactive inputs that are not allowed.

• A wiring error.

• Defective I/O: IN, INOP, INHA, INCN, INCT, INHAM.

1022 Run monitor - The run protect timer has expired. • Ran too long at leveling speed.

1023

Run monitor - The wrong direction run. The software issued a

command to run in one direction, but the car actually ran in

the other direction.

—

1024

Excessive number of re-levels - A fault is issued if the eleva-

tor re-levels more than 25 times within a 5-minute interval.

• A defective valve.

• A mis-adjusted valve.

1028

The selector shows the level outside of the door zone - The

inputs indicate that the car is level at the floor-at some loca-

tion other than within the door zone.

—

1029

LU and LD are active at same time - This fault indicates that

both level up and level down inputs are active at the same

time.

—

1030

Leveling sequence error - The leveling inputs were activated

in an invalid sequence.

—

1031 Selector setup error - The selector was not properly setup.

• Incorrect number of leveling vanes was detected.

• A bad floor position setup.

• The selector setup is incomplete.

• Scanning the hatch too fast.

1032

False slowdown interrupt - The slowdown interrupt was

detected with no active slowdown input.

—

1033

Selector position error - The selector position is out of step

with either the encoder, the slowdown, or the BP position.

—

1034

Expansion card error - The incorrect expansion card type was

returned.

• The wrong type of expansion card was installed.

• A defective expansion card or cable.

• An expansion cable was installed backwards.

• An incorrect expansion card type.

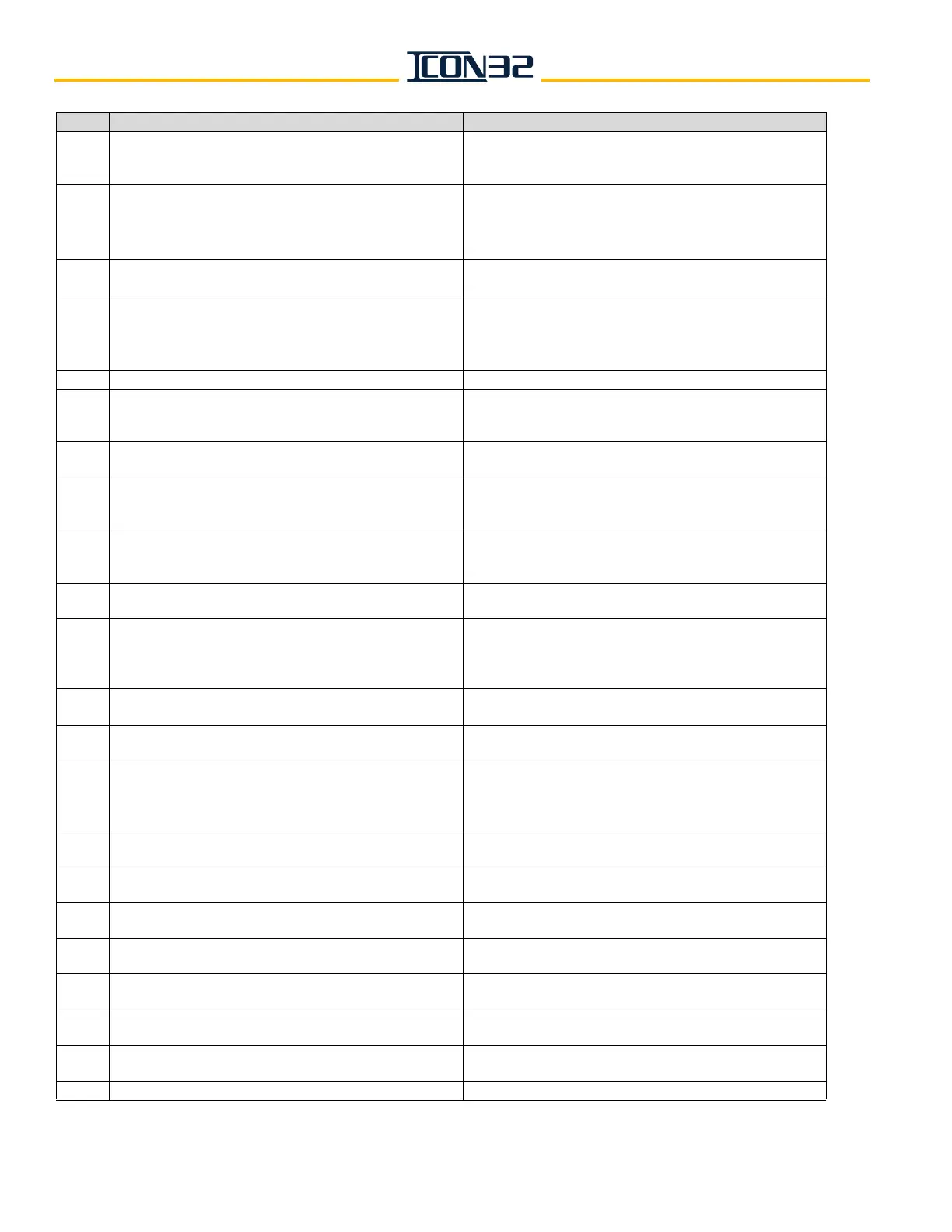

1040

Door watchdog closing failure - The DCL input did not acti-

vate within the expected time interval.

• An incorrect D21 and/or D22 adjustment. Door operator

faulted out or failed to provide the limit.

1041

Door watchdog opening failure - The DCL input did not acti-

vate within the expected time interval.

• An incorrect D21 and/or D22 adjustment. Door operator

faulted out or failed to provide the limit.

1042

Viscosity Shut Down due to over temperature – OLTO input is

(or was at some time) active.

Reset faults and cycle inspection switch to return car to service

once OLTO state is correct.

1043

Low Fluid Shutdown - The car did not complete a floor-to-

floor run within the low fluid timer (Z44) interval.

—

1044

Software error

- Both inputs are in the required state to acti-

vate and deactivate Fire Service Phase 1 at the same time.

—

1045

Software error - Both inputs are in the required state to acti-

vate and deactivate Fire Service Phase 2 at the same time.

—

1046

Failed to add I/O to the hardware assignments list - An invalid

I/O name was found.

—

1047 Calls canceled due to service interruption. —

Code Description (cont.) Possible Causes/Solutions (cont.)

Loading...

Loading...