DIAGNOSTICS

Vertical Express Product Manual 3-43 88500 v.1.0

Diagnostics Section SP Fault Codes - Safety Processor

This manual shows only the parameters that have an operational relevance to the ICON32. The UIT may have

additional parameters available, which should not effect the controller operation.

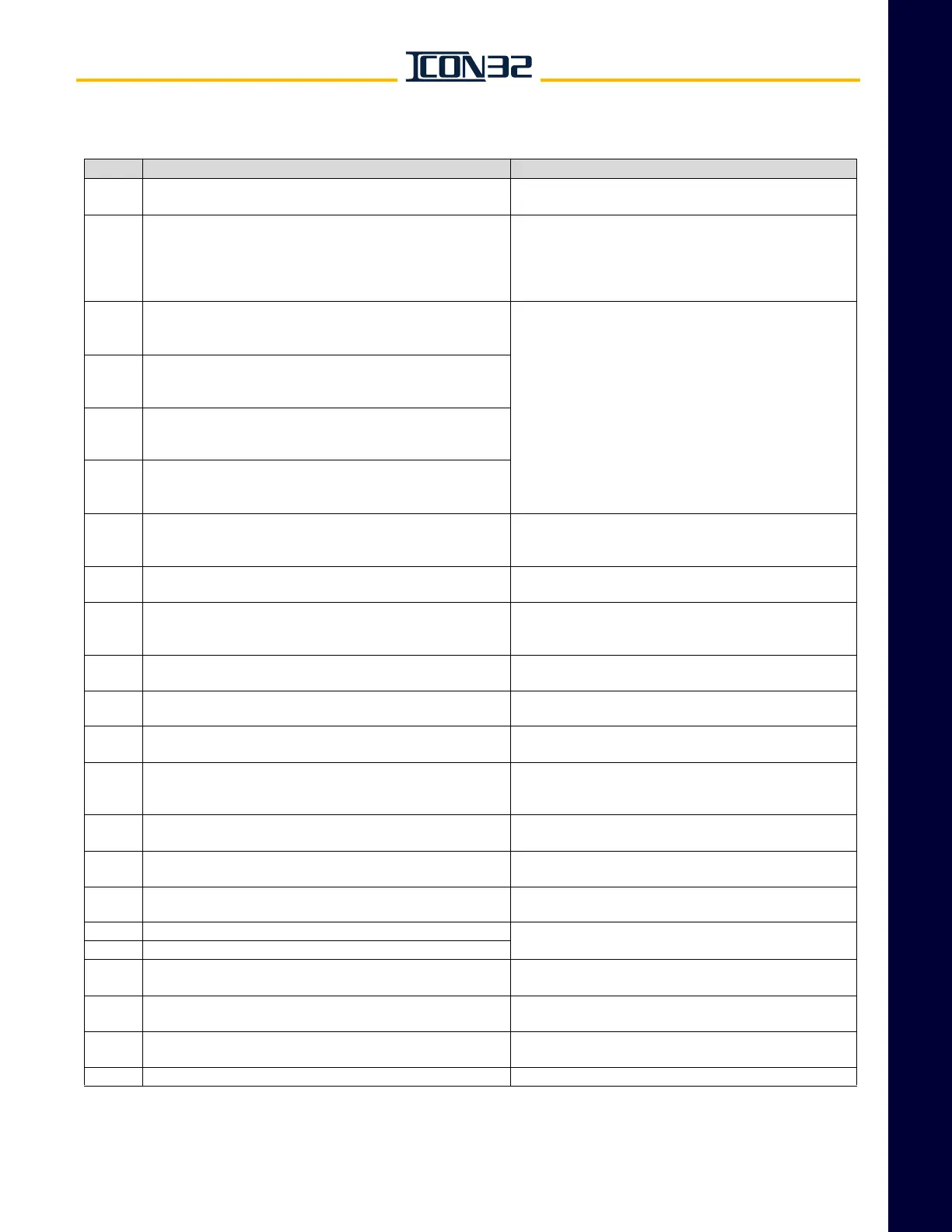

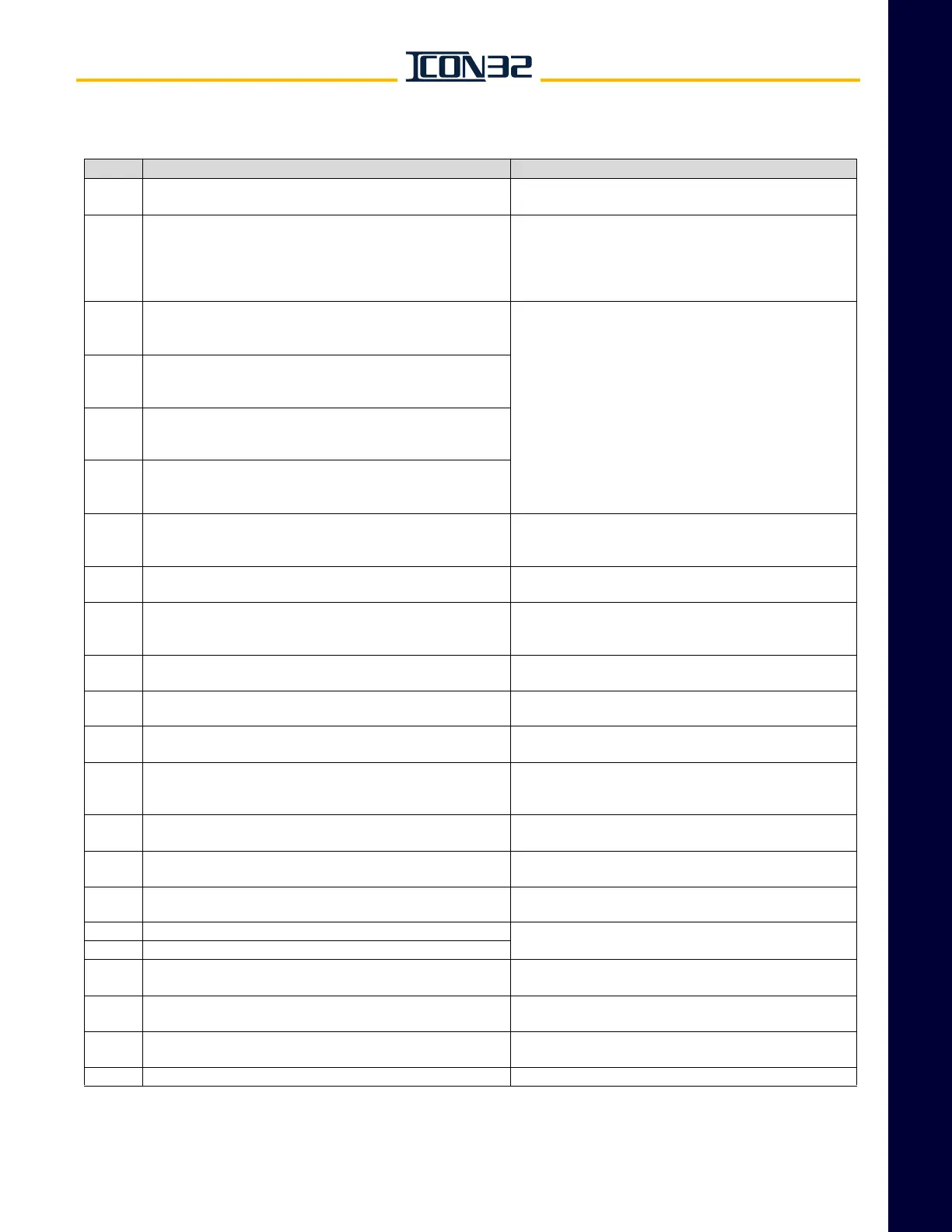

SP Fault Codes - Safety Processor

Code Description Possible Solutions

2701

Terminal speed reduction device activated – The SP detected

Up Fast active while the TSR1 or TSR2 magnets were active.

• Check the motor and valves

• Check the TSR1 and TSR2 magnets

2702

Excessive HWAC/Inspection speed detected – The SP

detected Up Fast or Down Fast active while on inspection

operation.The safety processor opens the safety string via the

SAFSP output.

• Check the motor and valves.

• Invalid encoder scaling.

• Invalid contactor monitor inputs.

• This condition is latched through a power cycle, and is

only reset through the SFR Command.

2703

Revert from car top inspection to automatic detected – The

SP detected Up or Down solenoids active while on car top

inspection without car top inspection run inputs.

• Failed outputs on the IOF Card.

• Check solenoid output wiring and voltages.

• Voltage present on outputs with no demand means

failed IOF Card output device(s).

2704

Revert from bypass operation to automatic detected - The

SP detected Up or Down solenoids active while on bypass

operation.

2705

Revert from hoistway access operation to automatic detected -

The SP detected Up or Down solenoids active while on hoistway

access operation without hoistway access run inputs.

2706

Revert from machine room inspection to automatic detected -

The SP detected Up or Down solenoids active while on machine

room inspection without machine room inspection run inputs.

2707 During car top inspection an invalid I/O was detected.

• Check the car top inspection inputs.

• Check the car CAN channel.

•Check the DPIA.

2708 During bypass operation an invalid I/O was detected.

• Check the car door bypass switch.

• Check the hoistway door bypass switch.

2709 During hoistway access operation an invalid I/O was detected.

• Check the hoistway access inputs.

• Check the car CAN channel.

•Check the DPIA.

2710 During machine room inspection, an invalid I/O was detected.

• Check the machine room inspection switch.

• Check the machine room inspection buttons.

2711

Bottom limit override crosscheck failure - The SP detected that

BLO and BLOM are in the same state.

•Check BLO.

•Check BLOM.

2712

The test outputs were not commanded within three (3) auto-

matic runs.

• Reload the generic and job software.

•Replace the CPU Card.

2713 Safety string output test failure.

• Check Real Time Motion > Show Faults

• Check all wiring/connections to the IOF Card.

• Replace the IOF Card.

2714 CHKHA crosscheck failure.

• IOF Card device failure - Try RFL, TFR, and cycle INSP to

reset. If it returns or is chronic, replace the IOF Card.

2715 TSMC data message was not received.

• Check the car CAN channel.

•Check TSMC.

2716 Car top data message was not received.

• Check the car CAN channel.

•Check the DPIA.

2717 Top hoistway access data message was not received.

• Check the hall CAN channel

•Check the HN Board

2718 Bottom hoistway access data message was not received.

2719 A corrupted TSMC Node A CAN message was received.

• Check Car CAN loading, connections, and cable routing.

•Replace the TSM Card.

2720 A corrupted TSMC Node B CAN message was received.

• Check Car CAN loading, connections, and cable routing.

•Replace the TSM Card.

2721 A corrupted car top CAN message was received.

• Check Car CAN loading, connections, and cable routing.

•Replace the DPIA Card.

2722 A corrupted top hoistway access CAN message was received. —

Loading...

Loading...