Terminal Slowdown Check Adjustment Section

©Vertical Express 2-36 Printed in USA April 2020

Verify Proper Function of the DOWN Terminal Slowdown Magnets via the UIT

1. In the UIT, scroll to Block Select Adjustments > Adjust Car/Group > Position System >

P18, and press ENTER to edit the value.

2. Press UP or DOWN to adjust P18 to one half of the recommended value from Table 3.

3. Place the car at the first non-close floor above the bottom terminal landing. This action

will allow the car to achieve contract speed in the down direction.

4. Run the car to the bottom terminal landing.

• NTSB should activate, slow the car down, and stop the car within the door zone.

• The controller should log faults (981,2801, 1062, etc.) showing the NTS system

was activated.

In the next step, a metal scribe will damage the tape.

a. If the car does not stop within the door zone, use a marker that will not damage

the selector tape to mark the bottom edge of the slowdown magnet’s current

location.

b. Use the alignment tool as a guide, and slide the slowdown magnets down in

1" increments. Repeat until the car stops within the door zone.

5. Restore P18 to the value indicated in Table 3. If the slowdown magnets had to be

repositioned to achieve proper operation, add 43 to the value of P18 for each inch the

magnets were moved.

6. Scroll to Block Select Adjustments > Adjustment Car/Group > Car Adjustments > WRT,

and issue a WRT Command to save the adjustments.

7. Attach each magnet in its final location with two small beads of silicone caulk. See

Figure 10 on page 2-34.

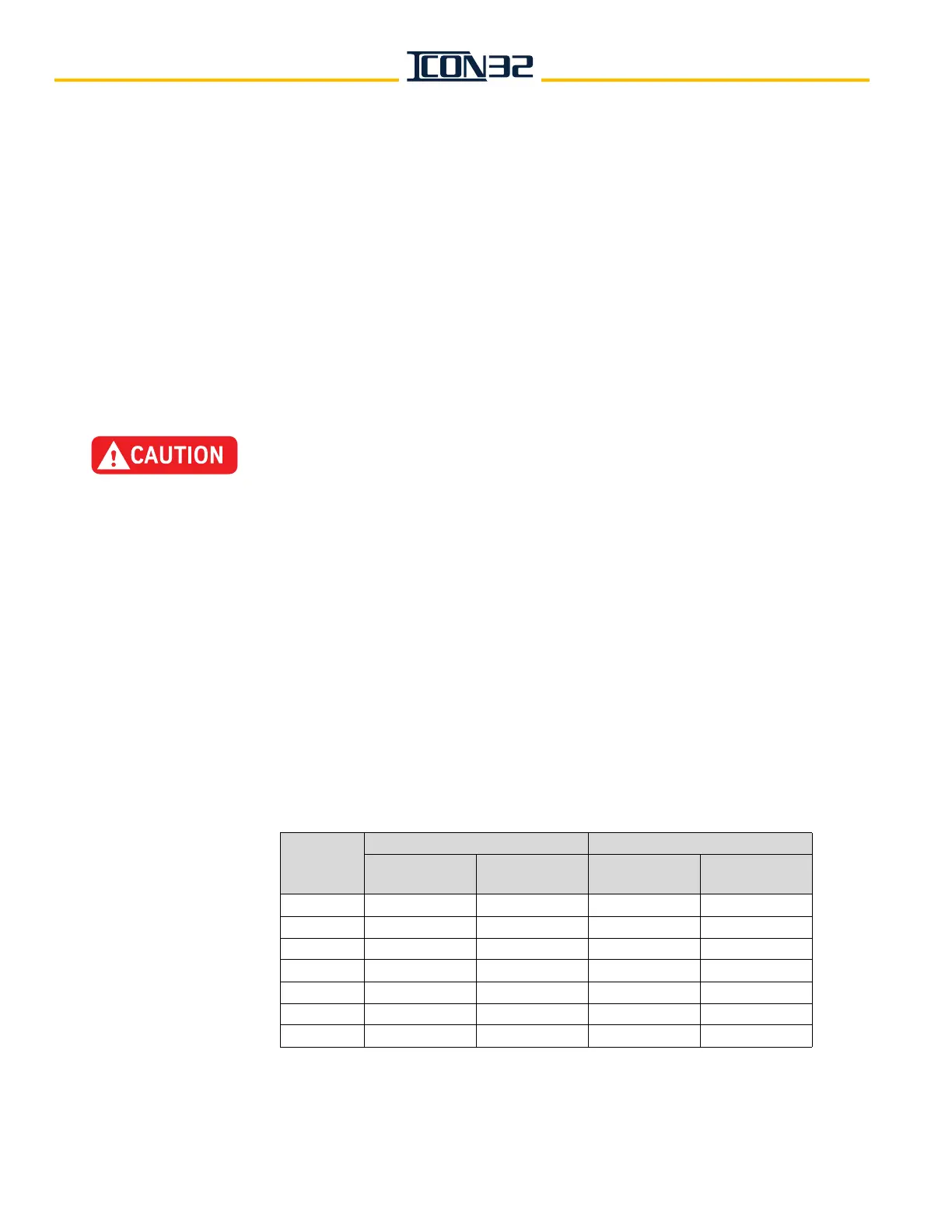

Table 3 - Selector Slowdown Distance

Car

Speed

(FPM)

Up Adjustment Down Adjustment

Distance

Slowdown

Count

Distance

Slowdown

Count

50 11" 470 8" 342

75 16" 683 12" 512

100 22" 939 16" 683

125 28" 1195 22" 939

150 34" 1451 28" 1195

175 42" 1792 34" 1451

200 50" 2134 42" 1792

Loading...

Loading...