ADJUSTMENT

Vertical Express Product Manual 2-7 88500 v.1.0

Adjustment Section Preliminary Adjustment

Software Verification Procedure

(continued)

c. Press UP until VER displays, press ENTER, and window displays this data:

This controller contains software that is under AECO A17.7 Control. When

replacing boards or functions involving this controlled software, verify that

the replacement or updated software is the same version listed on the

580AMY marker attached to the controller.

Fill out the following chart. If any processor/node reports version zero (0), the device

is not communicating; see Troubleshooting.

Safety Processor Verification

1. Verify that the Controller Inspection Switch is on INSP.

2. Use the following information to verify that either the SP Good LED or the SP Bad

LED is illuminated.

• SP Good LED illuminated: Continue to CAN Node Address Assignment on

page 2-8.

• SP Bad LED illuminated: Continue to CAN Node Address Assignment on

page 2-8.

The SP Bad should be glowing until the safety nodes are online and

indicate a ready to run condition. Configure the Safety Processor if

the IOF Card was exchanged with another controller.

• SP Good/SP Bad LEDs toggle back and forth: The Safety Processor is not

configured. Continue to the next procedure.

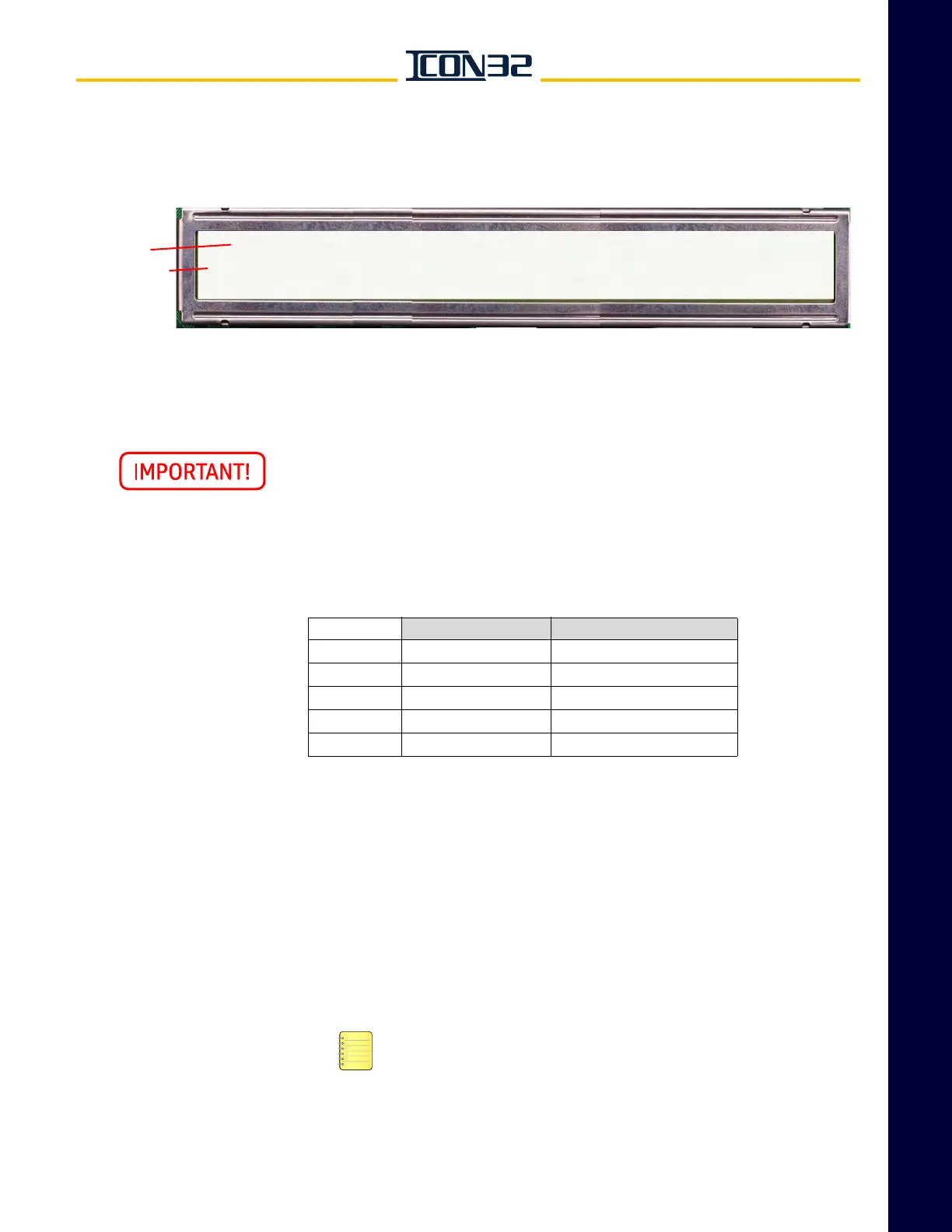

Top Line

Bottom Line

v = version

x = version number

r = revision

y = revision number

• If any of the safety nodes are offline, the car is shutdown and a fault is logged.

• Background color removed for clarity.

JOB:xxxnnn CPUC:vxry, CPUCfpga: vxry, IOFfpga:vxry

SP: vxry, SP:fpga:0, NP: vxry, CWILA:vx, CWILB:VX, SELA:vx,

SELB:vx, HNBTopA: vx, HNBTopB:vx, HNBBotA:vx, HNBBotB: vx

Definition Installed Software Version

CPUC Controller Generic

SP Safety Processor

NP Normal Processor

SELA Selector Node A

CWIL/DPIA DPIA Node A

Loading...

Loading...