Operation

0750−1/A1

Winterthur Gas & Diesel Ltd.

3/ 18

If one of the limits of the system oil is at a value given in the table above, applicable

procedures must be done to correct the problem. Such procedures can be purification

(decrease of the flow rate, adjustment of temperatures), treatment in a renovating

tank (settling tank) or partial exchange of the oil charge. It is recommended that you

speak to the oil supplier in such a condition.

The oil condemnation limits are given in Table 2. If the oil condition has so much

deterioration that the purifier and filters cannot make the condition better, some of the

oil charge must be replaced. The oil charge will then go back to a satisfactory

performance level.

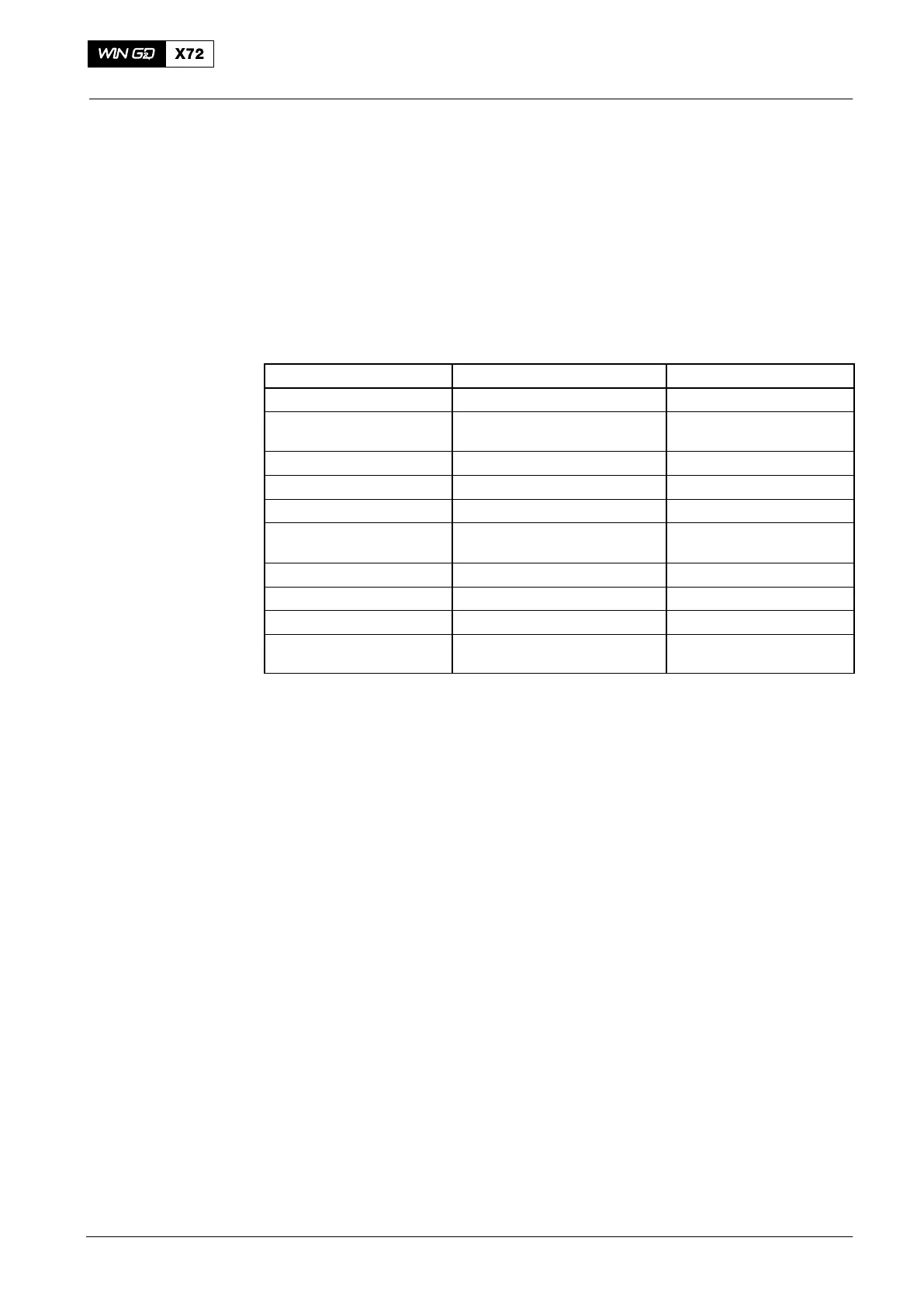

Table 2: Condemnation Limits

Parameter Limit Test Method

Viscosity at 40_C Maximum 150 mm

2

/s [cSt] ASTM D 445

Flash point (PMCC)

Minimum 180_C

ASTM D 92

Total insolubles Maximum 1.0% m/m ASTM D 893b

Base Number (BN) Maximum 15 mg KOH/g ASTM D 2896

Water content Maximum 0.30% m/m ASTM D 95

Strong Acid Number

(SAN)

nil mg KOH/g ASTM D 664

Calcium Maximum 6000 mg/kg [ppm] ICP

Zinc Minimum 100 mg/kg [ppm] ICP

Phosphorous Minimum 100 mg/kg [ppm] ICP

FZG gear machine test Minimum failure load stage 8 ISO 14635-1 (test

method A/8.3/90)

These limits are a guide. The condition of the oil in the system cannot be fully

calculated by one parameter. Other oil parameters must be used to find the cause of

the problem, and the applicable treatment.

If the Base Number (BN) of the system oil increases suddenly, do a check of the

piston rod gland box and piston rod condition.

Some consumption and replenishment of the system oil is necessary to keep the oil in

good condition.

If there is an important decrease in the flash point below the recommended value

shown above, Wärtsilä Services Switzerland Ltd. recommends a replenishment of the

oil charge.

A replacement of the oil charge prevents an increase in the system oil BN. A small

increase in BN is often an indication that the system oil consumption is low.

The open cup type of flash point test procedure (e.g. COC) must be used to decide if

some of the oil, or a full oil change is necessary. The closed cup type of flash point

test procedure (e.g. PMCC) can be used to monitor the system oil condition, but not

for oil change.

The FZG performance (to the procedure in ISO 14635−1) of the oil is important if a

new gear wheel is installed or was polished. This gives protection against scuffing

during the running-in of the gears.

2016−11

Lubricating Oils

Loading...

Loading...