Operation0750−1/A1

Winterthur Gas & Diesel Ltd.

2/ 18

2.1 Oil Care

2.1.1 System Oil

To keep the lubricating oil in good condition for long periods, good oil treatment is

necessary. To do this, a self-cleaning, centrifugal separator is used.

The self-cleaning, centrifugal separator is used as a purifier in by-pass mode. The oil

flows from the oil tank through the centrifugal separator. The system oil volume must

be put through the centrifugal separator a minimum of three times each day. The

manufacturer of the centrifugal separator sets the output. The recommended oil

temperature for this treatment is 95_C unless the centrifugal separator supplier

recommends differently.

Solid contaminants (dirt) and water must be removed from the oil as completely as

possible. There is always a risk that water, specially sea water, can enter the system

and cause corrosion on engine parts. Water contamination can also cause bacterial

infection of the oil, which gives a decrease in lubrication and heavy corrosion of the

system. Good maintenance is the best precaution to keep water out of the oil. The

water content of the lubricating oil must not be more than 0.2% by mass during a long

period. If higher water contamination is seen, special procedures such as treatment in

the centrifugal separator, or in a renovating tank must be done.

The coarse and fine filters of the servo oil system must be serviceable. For more

data, see the documentation of the fine filter manufacturer and paragraph 2.3.2.

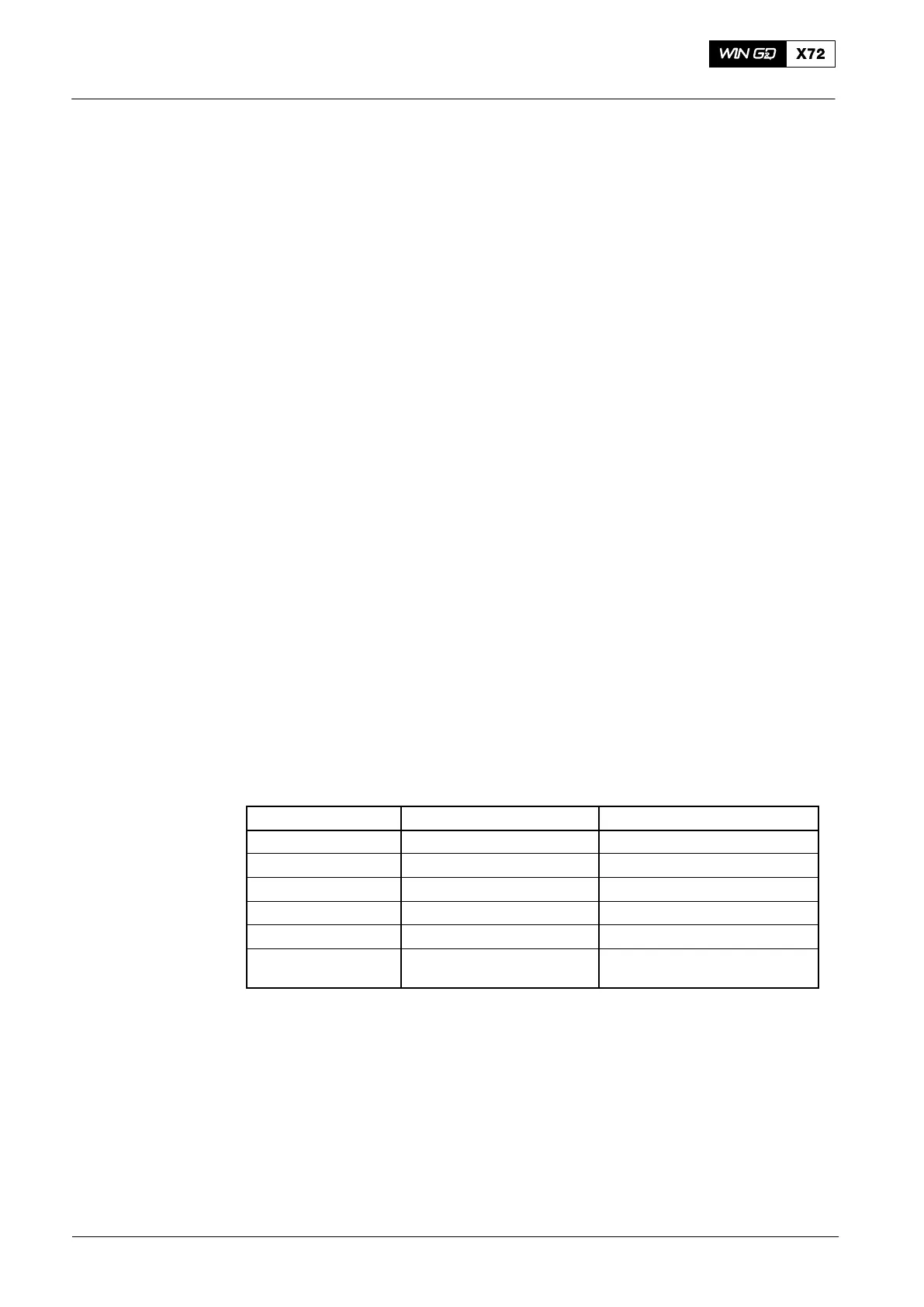

2.2 Limits for Selected System Oil Parameters

You make an analysis of the selected parameters to estimate the condition of the

lubricating system oil. Regular checks can find deterioration early and procedures can

be done to correct the problems.

Make sure that the limits of the system oil are not more than those given in the

Table 1 for long periods in service.

Table 1: Alert Limits of System Oil Parameters

Parameter Limit Test Method

Viscosity at 40_C

Maximum 140 mm

2

/s [cSt] ASTM D 445

Flash point (PMCC)

Minimum 200_C

ASTM D 92

Total insolubles Maximum 0.70% m/m

1)

ASTM D 893b

Base Number (BN) Maximum 12 mg KOH/g ASTM D 2896

Water content Maximum 0.20% m/m ASTM D 95 or ASTM D 1744

FZG gear machine

test

Minimum failure load

stage 9

ISO 14635-1(test method

A/8.3/90)

1) % m/m means by mass, e.g. a water content of 0.20% m/m means that the water

content is 0.20% of the mass of the total solution.

2016−11

Lubricating Oils

Loading...

Loading...