Operation

4002−1/A1

Winterthur Gas & Diesel Ltd.

9/ 22

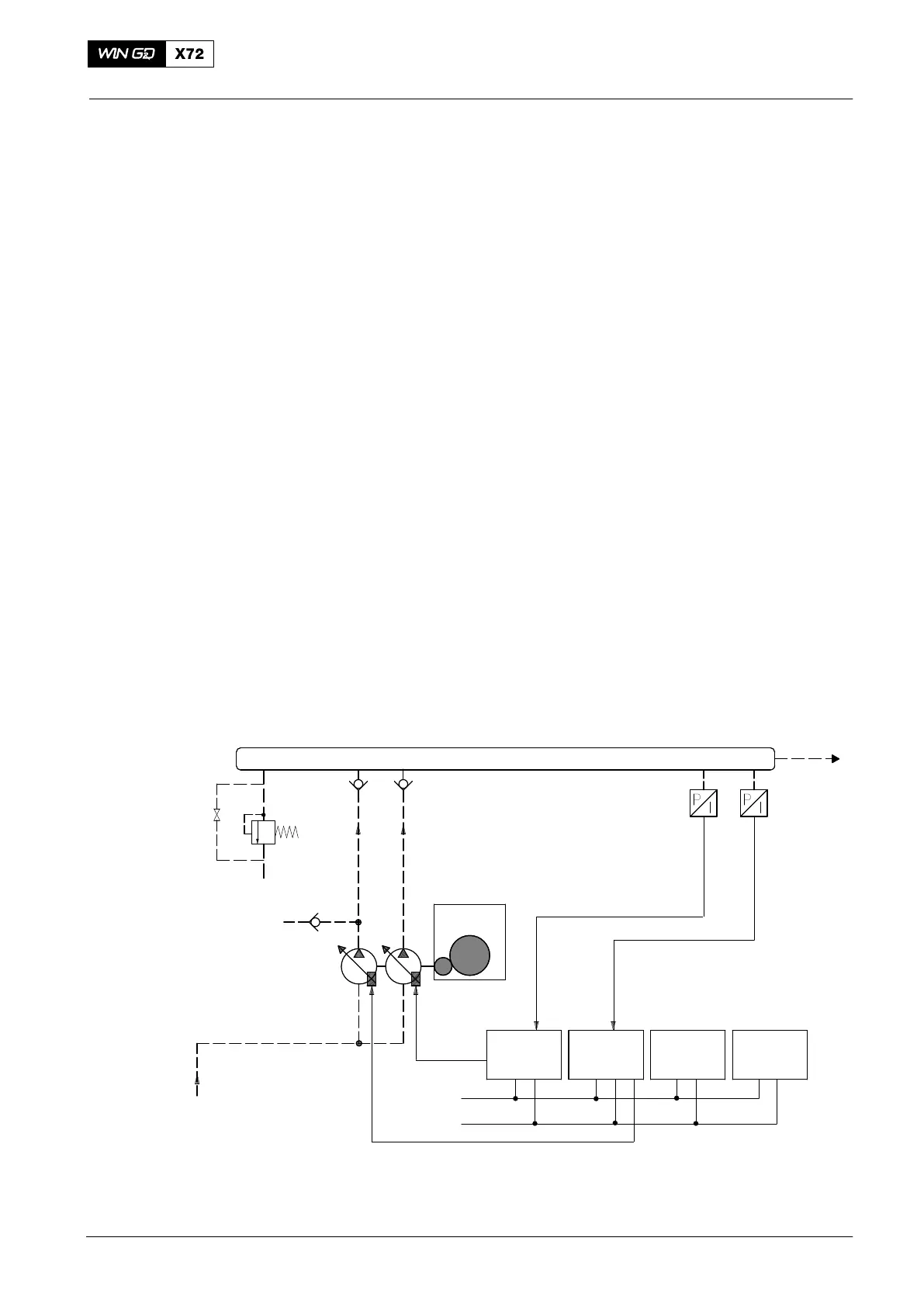

3.2 Servo Oil Pressure Control

3.2.1 Pressure Setpoint

The internal controller of the servo oil pumps keeps the basic servo oil pressure.

The load dependent changes in servo oil pressure is controlled by the CCM-20 Cyl. 3

(with the signal CV7221C to servo oil pump #1) and CCM-20 Cyl. 4 (with the signal

CV7222C to servo oil pump #2).

To close the control loop the feedback signal from the servo oil rail pressure

transmitter PT2071C is send to CCM-20 Cyl. 3 and from PT2072C to CCM-20 Cyl. 4.

3.2.2 Emergency Mode

If one servo oil pump becomes defective, the system will continue to operate. The

other servo oil pump will continue to supply the necessary pressure to the servo oil

rail. If both servo oil pumps have an electrical failure, the engine can still operate at

low load.

3.2.3 Monitored Items

The servo oil pressure is monitored. If the servo oil pressure is out of the tolerance, a

failure indication is shown on the LDU-20.

The sensors are monitored. If the sensors are out of range, an alarm is triggered in

the AMS and a failure indication is shown on the LDU-20. If both servo oil pressure

sensors have a failure, the engine can still operate at low load.

The leakage of the servo oil pumps is monitored. If there is too much servo oil

leakage, the AMS triggers an alarm.

Supply Unit

Drive

Connection

for Servo Oil

Service Pump

Servo Oil Pumps

with Internal

Pressure Controllers

CCM−20

Cyl. 4

CCM−20

Cyl. 3

CCM−20

Cyl. 2

CCM−20

Cyl. 1

Servo Oil Rail

Exhaust Valve

Control Units

Main Bearing Oil

CANBus

PT2072C

CV7221C

PT2071C

CV7222C

Safety

Valve

Fig. 4: Servo Oil Pressure Setpoint

Engine Control System

2015-12

Loading...

Loading...