Operation

4003−1/A1

Winterthur Gas & Diesel Ltd.

5/ 11

4.3 ECS Start

1) In the power supply boxes E85.1 to E85.x, set all the knife switches to on.

2) On all the CCM-20, MCM-11, IOM-10 and the two LDU-20, make sure that all

green LED indications come on.

4.4 Safety and Alarm System

1) Make sure that the remote control system (RCS), engine safety system (ESS),

alarm and monitoring system (AMS) are set to on.

2) On the control room console and the local control panel, push the EMERGENCY

STOP button. Make sure that the pressure control and safety

valve 10-5562_E0_5 is electrically operated (i.e. the coil is energized). This

causes an alarm (M/E Emergency Stop) in the AMS. The alarm is shown on the

LDU-20 and the AMS.

3) Connect the pressure calibration hand-pump (tool 94050) to the applicable pipe

(e.g. the pipe that has the pressure sensor PS1101S).

4) Use the pressure calibration hand-pump (tool 94050) to increase the pressure to

more than the reference pressure given in Table 1.

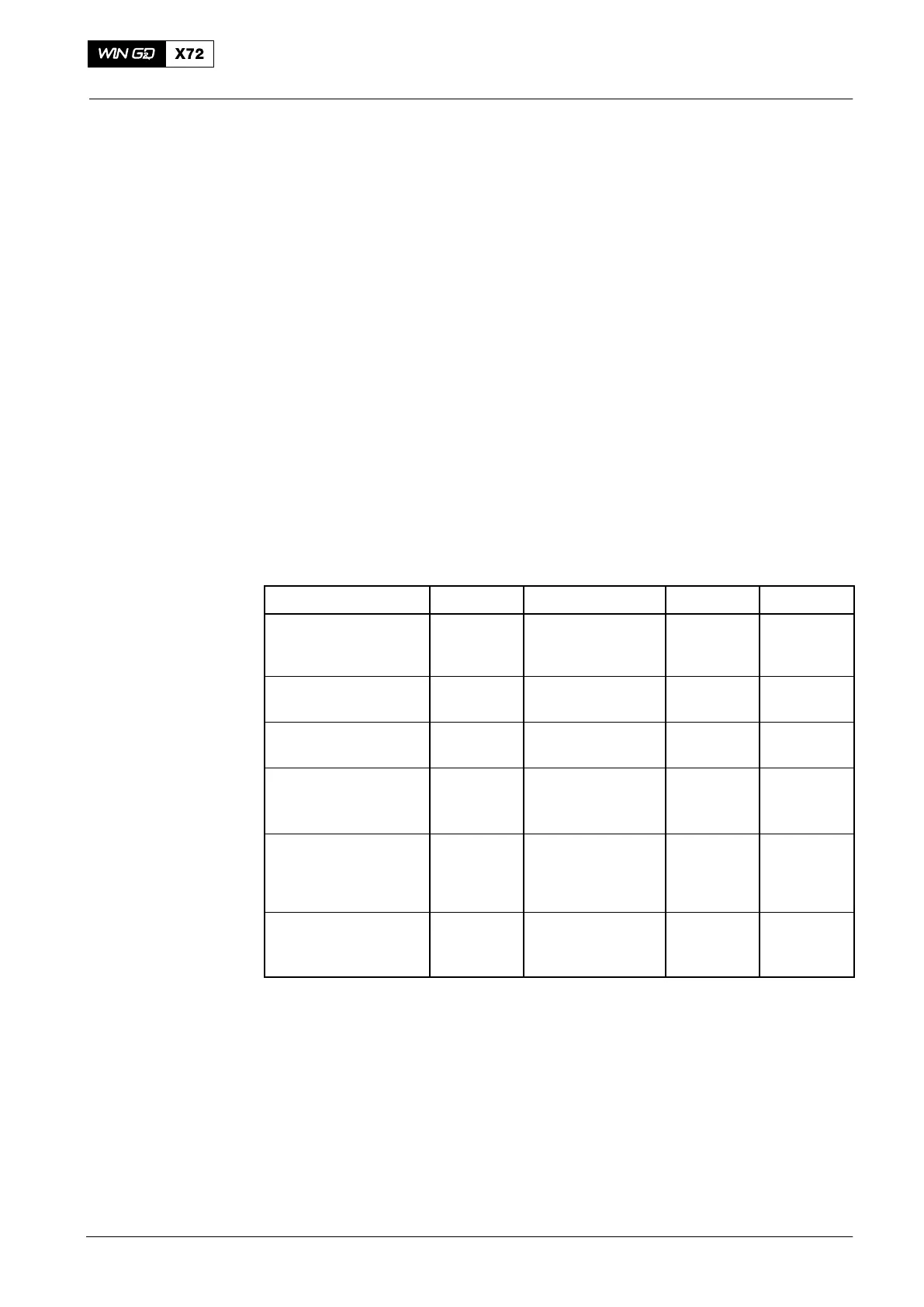

Table 1: Pressure Calibration

Medium Code No. Pressure Action Time delay

Cylinder cooling

water pressure

(engine inlet)

PS1101S less than 3.5 bar

(contract closed)

Shutdown 60 s

Main bearing oil

supply pressure

PS2002S less than 3.3 bar

(contract closed)

Shutdown 10 s

Air spring air pressure PS4341S less than 4.5 bar

(contract closed)

Shutdown 0 s

ABB Turbocharger

bearing oil pressure

inlet

PS2611S

and

PS2612S

less than 0.6 bar

(contract closed)

Shutdown 5 s

ABB Turbocharger

bearing oil pressure

inlet − independent oil

supply

PS2611S

and

PS2612S

less than 0.9 bar

(contract closed)

Shutdown 5 s

MET Turbocharger

bearing oil pressure

inlet

PS2611S

and

PS2612S

less than 0.4 bar

(contract closed)

Shutdown 5 s

Note: The data shown above are for reference only. For the applicable settings,

see 0250−2 Operating Data Sheet.

5) Make sure that the pressure switch opens.

6) Decrease the pressure in the pipe to set the pressure switch to the correct

pressure (e.g. 3.5 bar). Make sure that the pressure switch stays open.

7) Disconnect the pressure calibration hand-pump (tool 94050) from the pipe.

8) Do the steps above for the pressure switches PS2002S, PS4341S, PS2611S and

PS2612S.

2015-03

Engine Control

Loading...

Loading...