Operation8016−1/A1

Winterthur Gas & Diesel Ltd.

2/ 10

2.1 Dirty Oil Samples

2.1.1 Preparation

1) Write the applicable data on the oil analysis form (e.g. operation conditions, fuel

parameters, cylinder lubricating oil feed rate etc).

2) Make sure that the labels on the sample bottles refer to the related cylinders.

2.1.2 Procedure

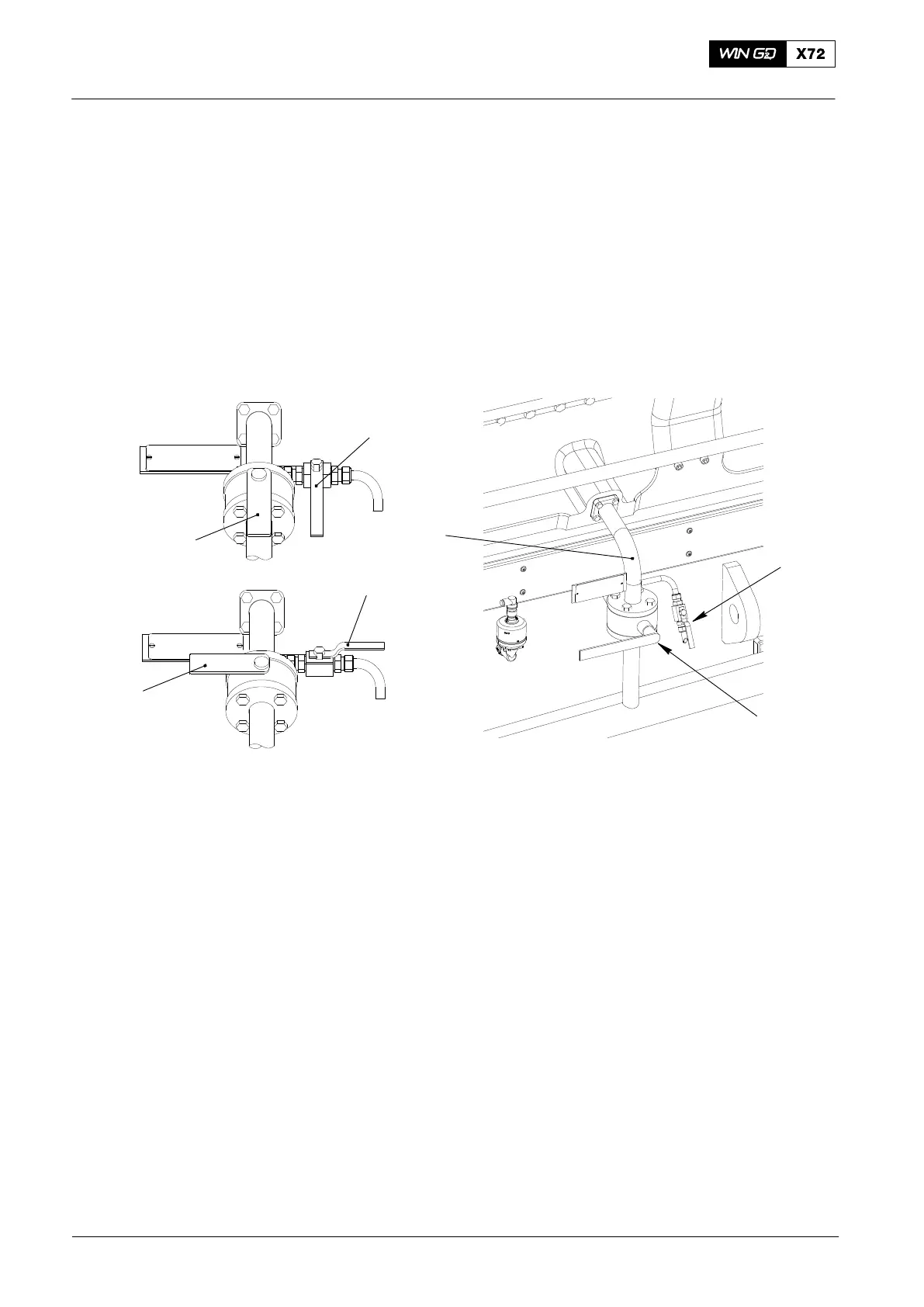

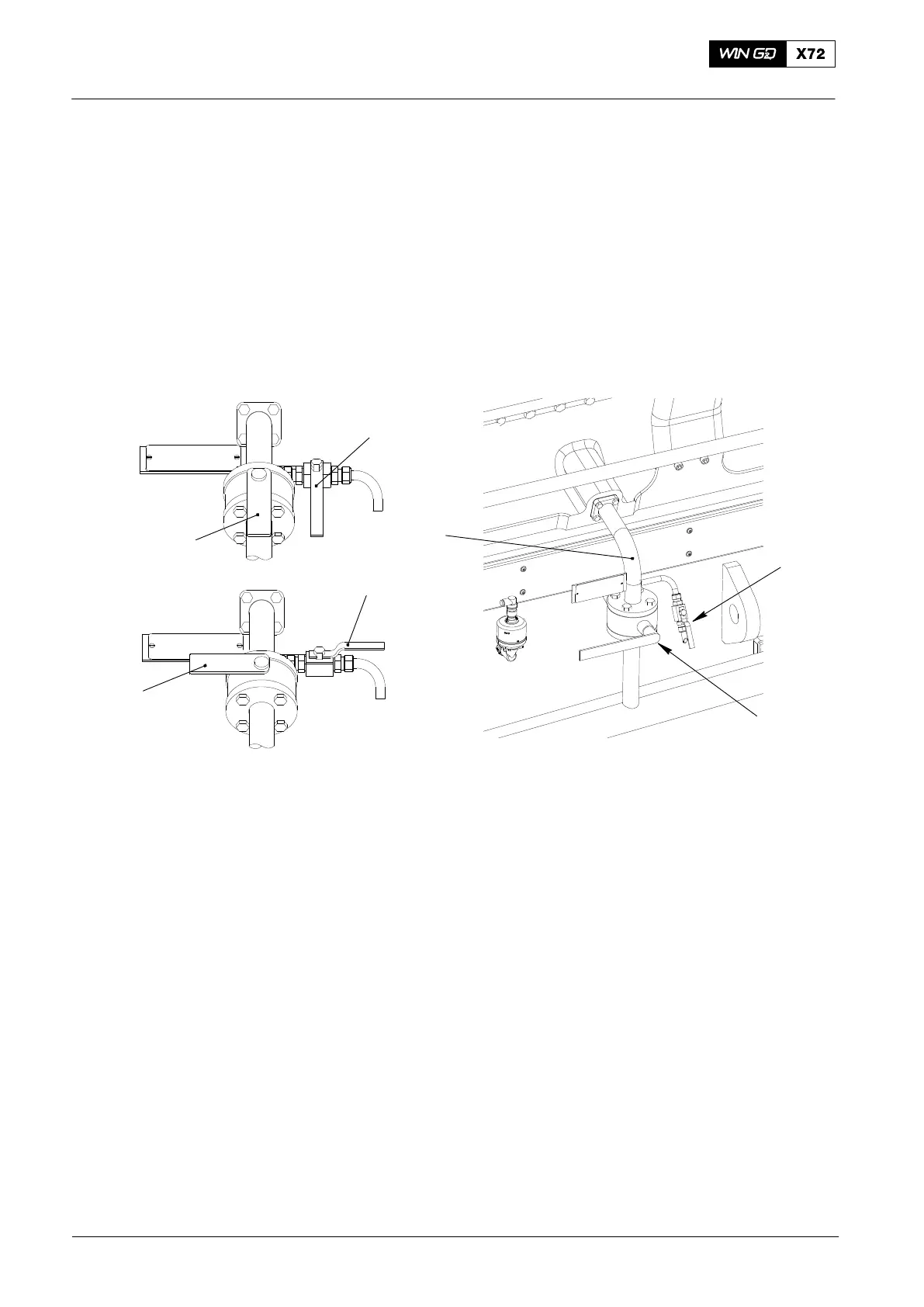

1) Close the ball valve (2, Fig. 1) for approximately 30 minutes to 60 minutes.

Note: Some parts can look different.

2

3

1

Closed

Open

1

2

2

1

Open

Closed

Ball Valve Positions

Fig. 1: Location of Ball Valves for Dirty Oil Samples

2) Put an applicable container under the ball valve (1).

3) Slowly open the ball valve (1) to flush out oil and possible dirt.

4) Close the ball valve (1).

5) Open the ball valve (2) to drain the remaining oil from the dirty oil pipe (3).

6) Close the ball valve (2).

7) Put the sample bottle under the ball valve (1).

8) After approximately 10 minutes to 60 minutes, slowly open the ball valve (1) to fill

the sample bottle.

9) Close the ball valve (1).

10) Open the ball valve (2) to drain the oil that collected in the dirty oil pipe (3).

11) Do the steps 1) to 10) again on each cylinder.

Note: Winterthur Gas & Diesel Ltd. recommends that you get an oil sample of

the cylinder lubricating oil downstream of the duplex filter. Send the oil

sample to the laboratory to make an analysis to make sure the initial

cylinder lubricating oil had the correct quality and no contamination.

12) Make sure that the sample bottles are tightly closed and use an applicable

package.

13) Send the samples to the laboratory to make an analysis.

Lubricating Oil System

2015-03

Loading...

Loading...