Operation

4002−1/A1

Winterthur Gas & Diesel Ltd.

13/ 22

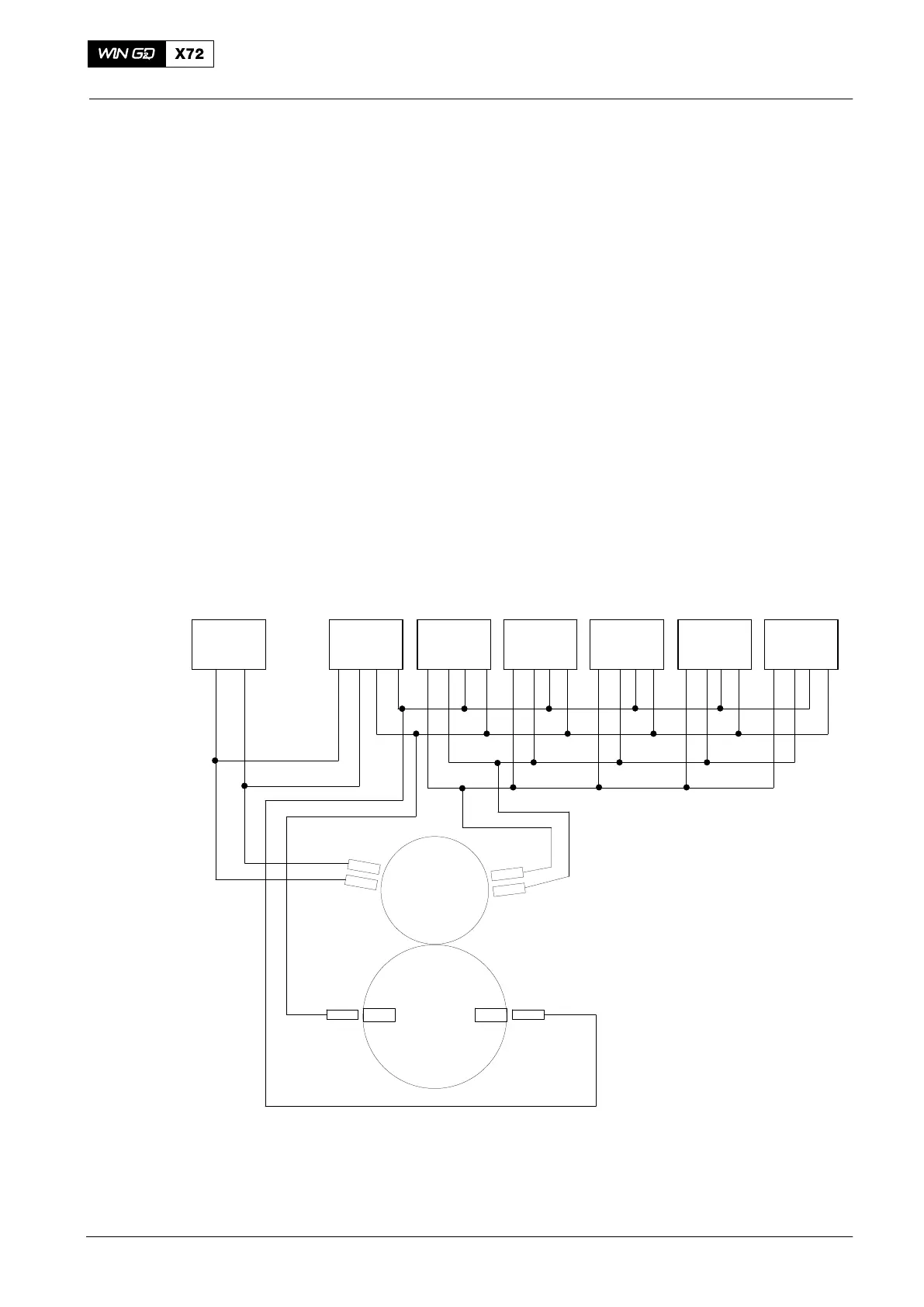

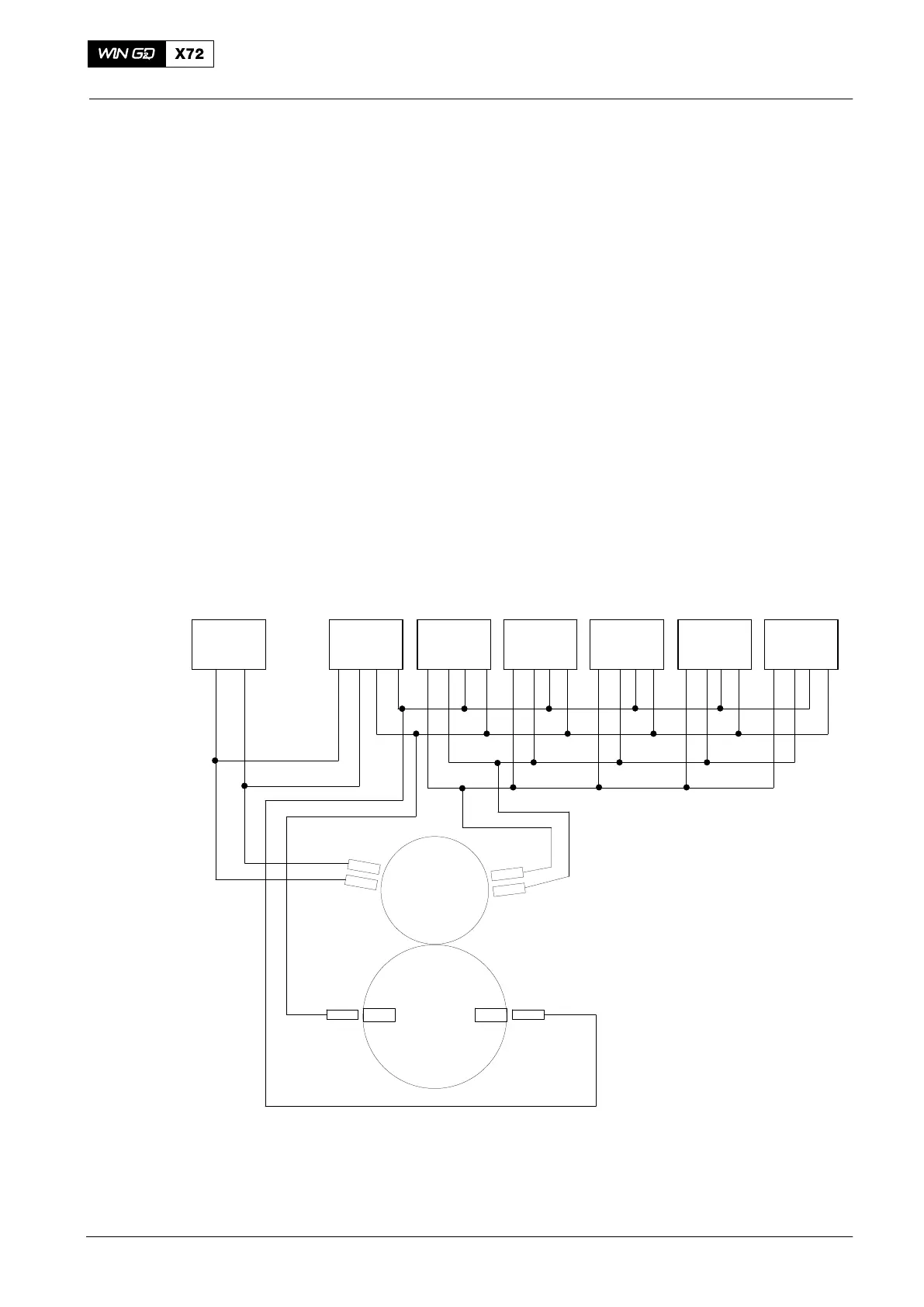

3.5 Engine Speed and Crank Angle Sensor

Four proximity sensors (A and B, C and D) are installed near the crankshaft gear

wheel (see Fig. 7). As the crankshaft gear wheel turns, the proximity sensors sense

the movement of the teeth and calculate the crankshaft position (see also

9223−1 Crank Angle Sensor Unit).

The inductive proximity sensors (speed pickups) A and B are connected to

CCM-20 Cyl. 1 and then looped to the MCM-11 (see Fig. 2).

The inductive proximity sensors (speed pickups) C and D are connected to

CCM-20 Cyl. 2 and then looped through to CCM-20 Cyl. n (see Fig. 2).

Additionally, one proximity sensor for TDC and one proximity sensor for BDC is

installed near the flywheel. These proximity sensors detect the reference marks

attached to the flywheel (see also 9223−1 Crank Angle Sensor Unit).

The crank angle is calculated incrementally by counting pulses (gearwheel teeth) from

the reference position to the current position in each CCM-20 individually.

The reference positions (TDC and BDC) are detected with separate sensors. The

reference points are the centers of the TDC and BDC marks.

To detect the sense of rotation there is always a pair of gear wheel sensors (A and B,

C and D). If one of the sensors fails the data (sense of rotation) is available on the

CANBus.

The reference sensor signals are used to synchronize the relative position signal to

the absolute crankshaft angle.

DATA FOR

6 CYLINDERS

CCM−20

Cyl. 1

CCM−20

Cyl. 2

CCM−20

Cyl. 3

CCM−20

Cyl. 4

CCM−20

Cyl. 5

CCM−20

Cyl. 6

Flywheel

Sensor

A and B

Crankshaft

Gear Wheel

Sensor

TDC

MCM−11

E25

Sensor

C and D

Sensor

BDC

Fig. 7: Crank Angle Sensors

Engine Control System

2015-12

Loading...

Loading...