February 2013

4-361

ColorQube® 9303 Family

REP 91.25

Repairs/Adjustments

CAUTION

If the marking unit has not been removed. Take care not to contact the printheads with the

drum during removal.

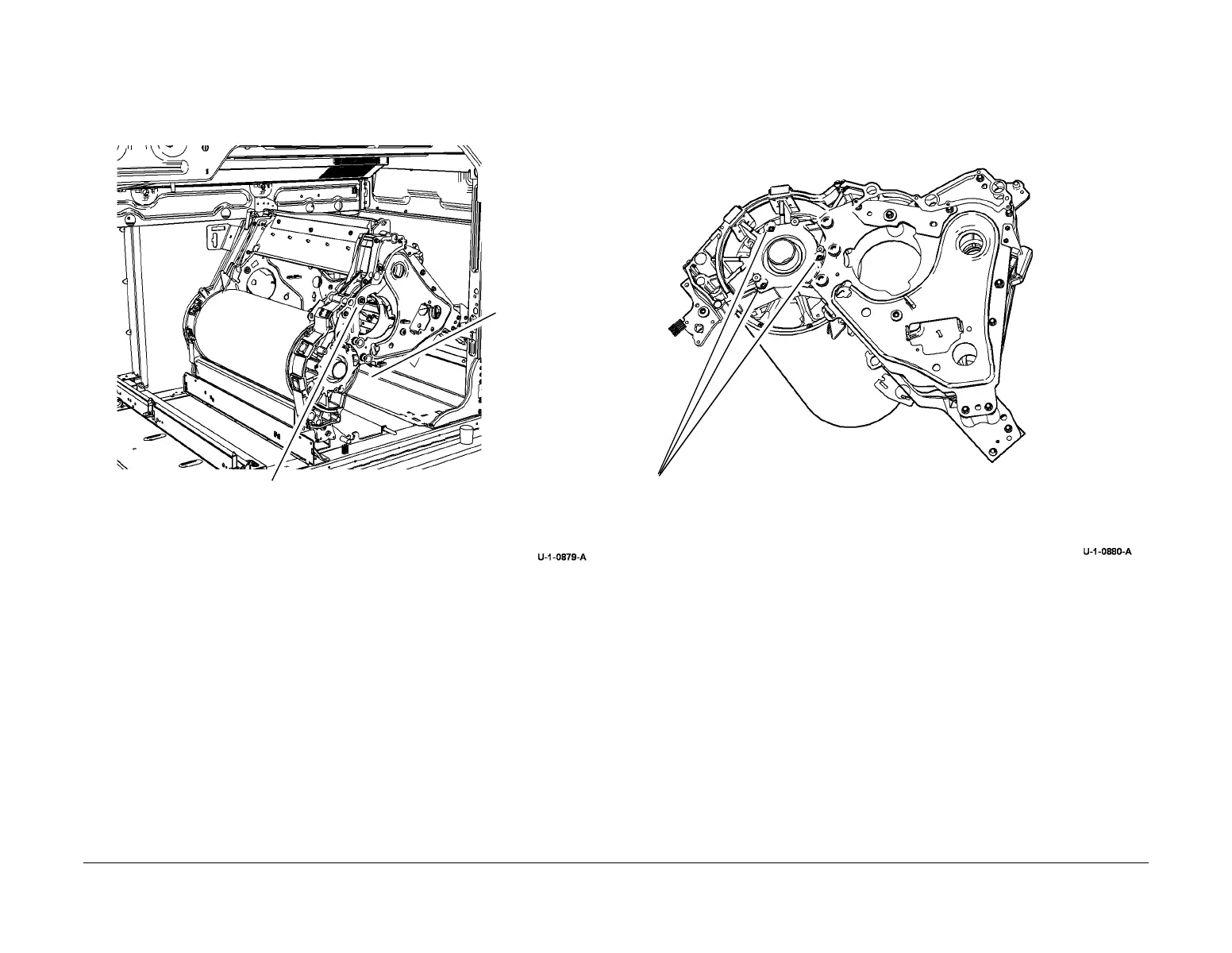

19. Remove drum and front drum frame assembly, Figure 3.

Figure 3 Removal

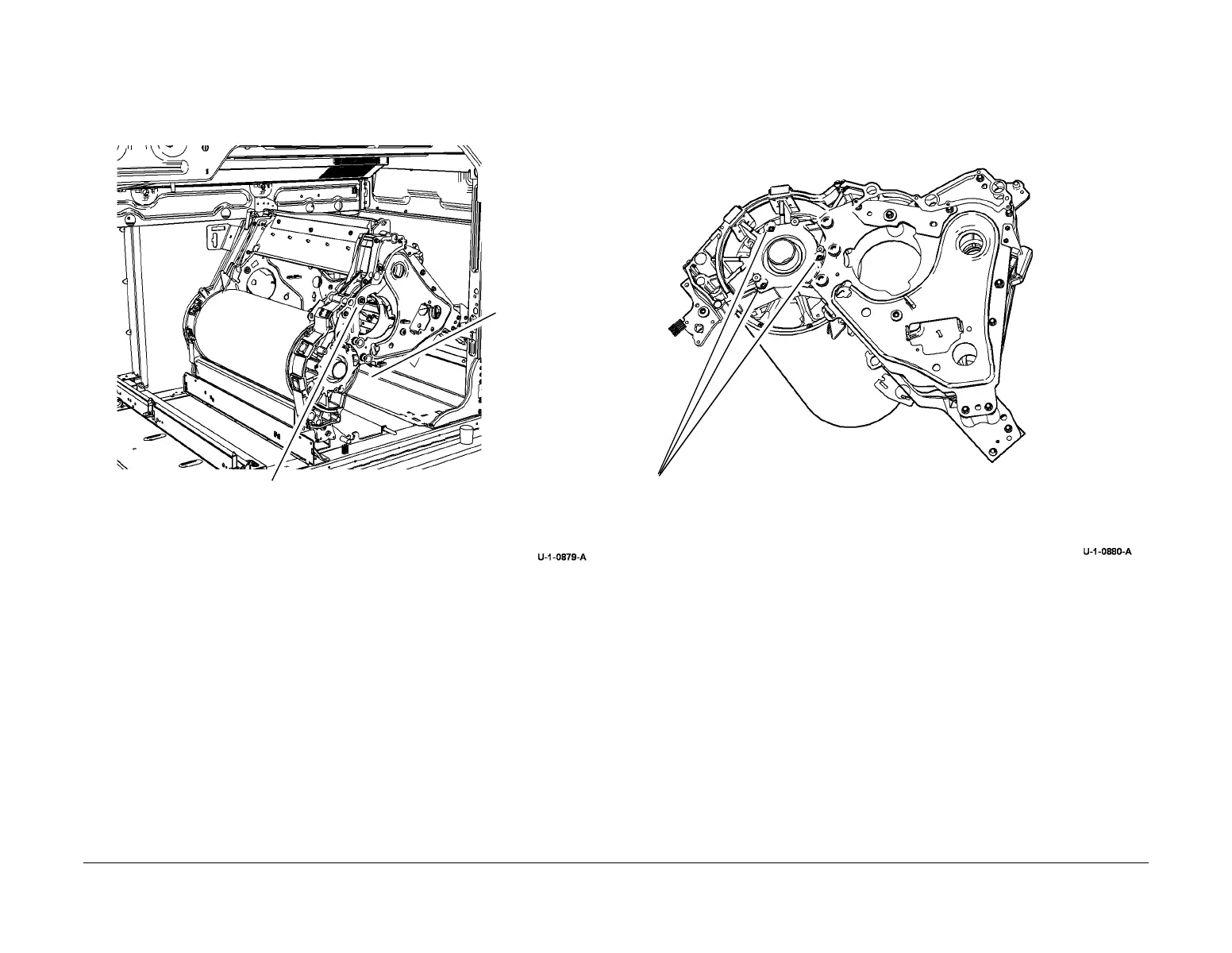

20. Release the drum from the front drum frame assembly, Figure 4.

NOTE: Use the top section of the replacement drum packaging to support the old drum.

This will help to keep the drum stable during the separation.

Figure 4 Release the drum

Replacement

Replacement is the reverse of the removal procedure. Observe the following points at the

appropriate steps.

NOTE: High pressure bearing grease, PL 26.11 Item 3, is used in the following locations.

• Drum bearing housing in the front drum frame casting.

• Drum pulley bearing housing in the rear drum frame casting.

• Outside diameter of the transfix roller bearing holder at the front of the transfix roller.

During normal removal and replacement the existing bearing grease used during manufacture

will be sufficient. Only apply grease when both sides of any bearing surface are being

replaced, or if the surfaces have been wiped clean. Apply the grease very sparingly.

1. A replacement drum will have a drum protector and drum alignment tool supplied with the

drum. Install these items onto the drum before installing the drum.

2. Attach the drum to the front drum frame assembly.

3

Remove the drum and

front drum frame assem-

bly by pulling them away

from the rear assembly.

1

Support the rear

underside of the

drum with right

hand through the

opening.

2

Hold front assembly

with left hand.

1

Remove 3 screws.

2

Separate the drum and front

drum frame assembly.

Loading...

Loading...