February 2013

3-29

ColorQube® 9303 Family

IQ 5, IQ 6

Image Quality

YN

Perform ADJ 91.1 Printhead Attachment Check.

Perform SCP 5 Final Actions.

Perform dC972 option 5, Y-dot position correction. Print TP 1 Initial Test Print Pages. Evaluate

the text page only and compare with IQS 6.

The text page is good.

YN

Perform dC972 option 1, Printhead Uniformity. Option 1 runs options 1 through 5, before

proceeding to run option 5, Print TP 1 Initial Test Print Pages. Evaluate the text page only

and compare with IQS 6.

The text pages are good.

YN

Perform dC972 option 5, Y-Dot Position Correction. Print TP 1 Initial Test Print

Pages. Evaluate the text page only and compare with IQS 6.

The text pages are

good.

YN

Install new printheads as necessary, PL 91.20 Item 2 or PL 91.25 Item 2.

Perform SCP 5 Final Actions.

Perform SCP 5 Final Actions.

Perform SCP 5 Final Actions.

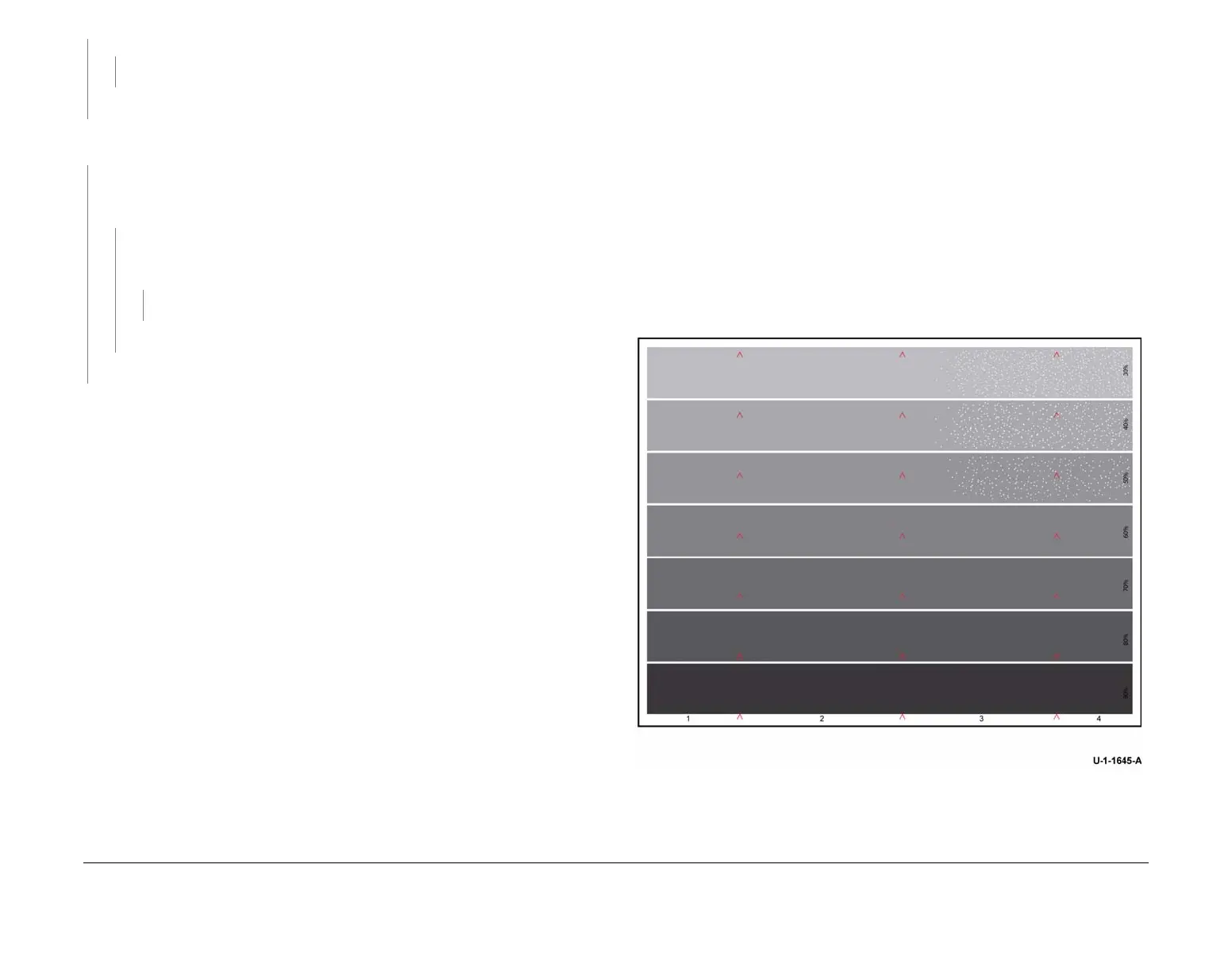

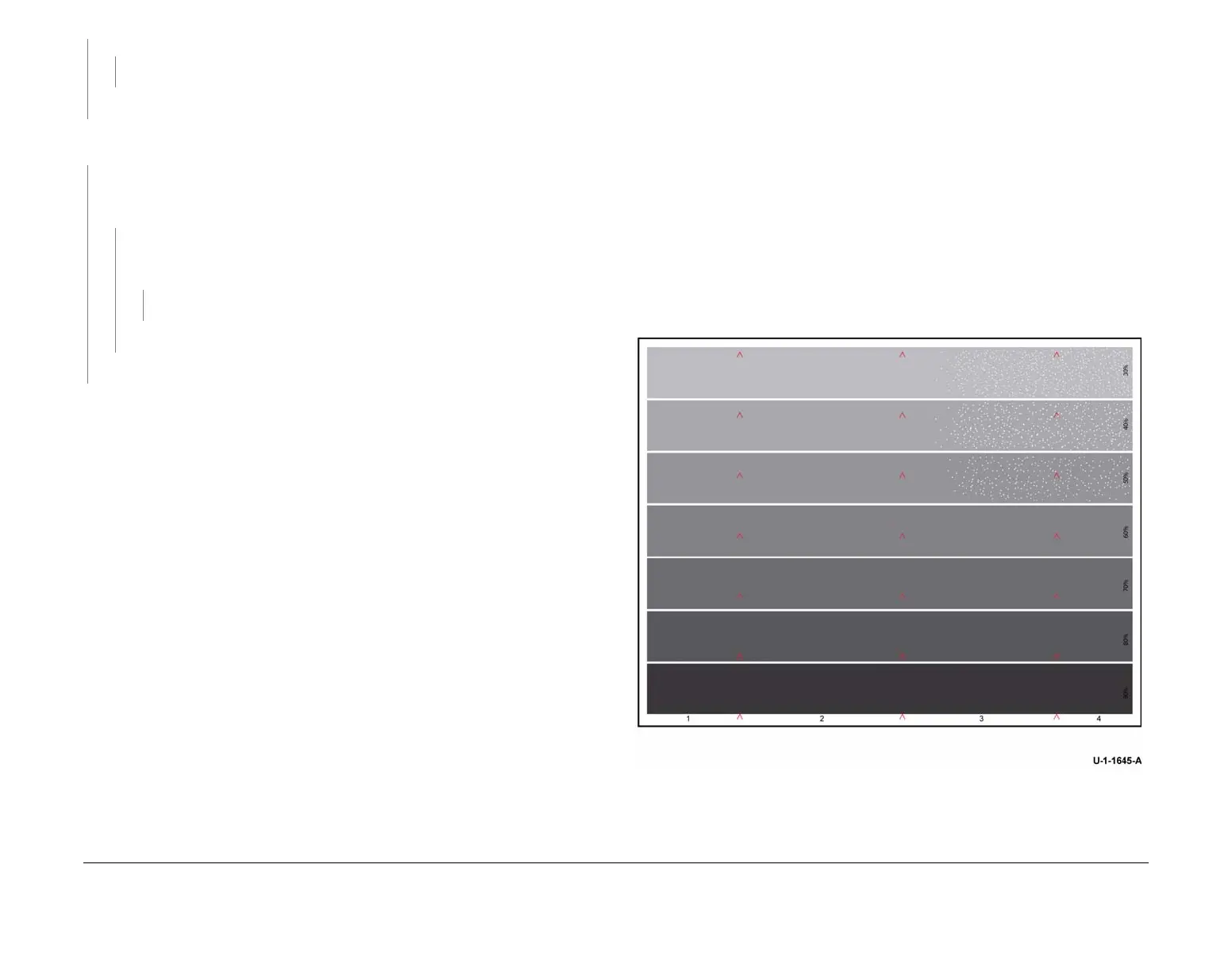

IQ 6 Missing Ink or Grainy Output RAP

Use this RAP when the output has white spots or a grainy appearance, Figure 1.

A grainy appearance can be caused by:

• Image processing on certain postscript print files that contain transition areas between

greys and near-greys.

• Inherent graininess in prints.

• Missing pixels (known as dropout). This is most visible in halftone regions and is most

prevalent on duplex prints and / or rough / textured media.

NOTE: Media containing cotton, linen or parchments can exhibit dropout due to surface tex-

ture. Areas of missing ink on envelopes that outline the seams or flaps is normal.

NOTE: Opening the paper tray or switching from SEF to LEF prints can cause dropout on the

next duplex print. Reprinting the job will normally resolve this issue.

Ensure IQ 1 Image Quality Entry RAP is performed before starting this RAP.

Figure 1 Duplex dropout example

C

Loading...

Loading...