Phaser 6121MFP Service Manual 2-41

Theory of Operation

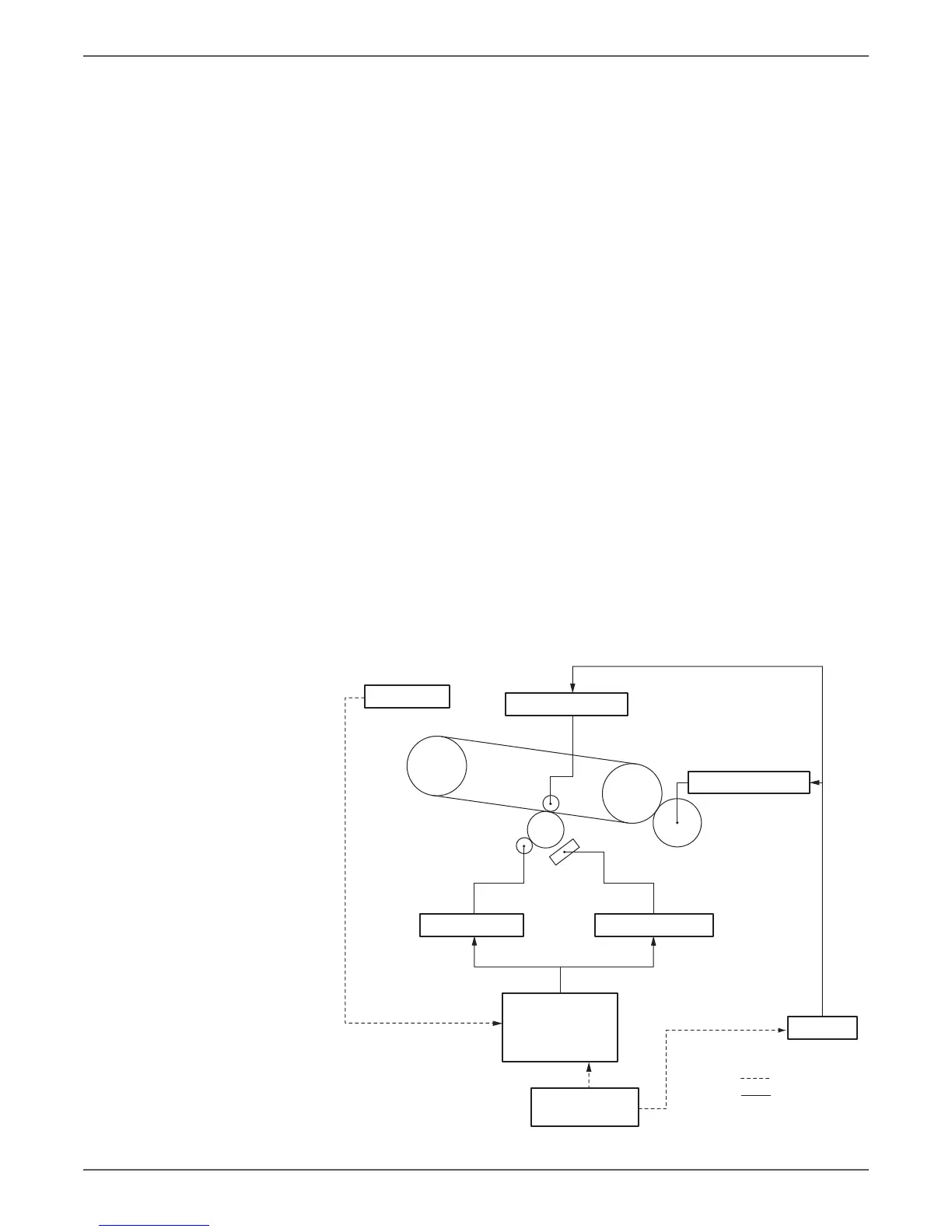

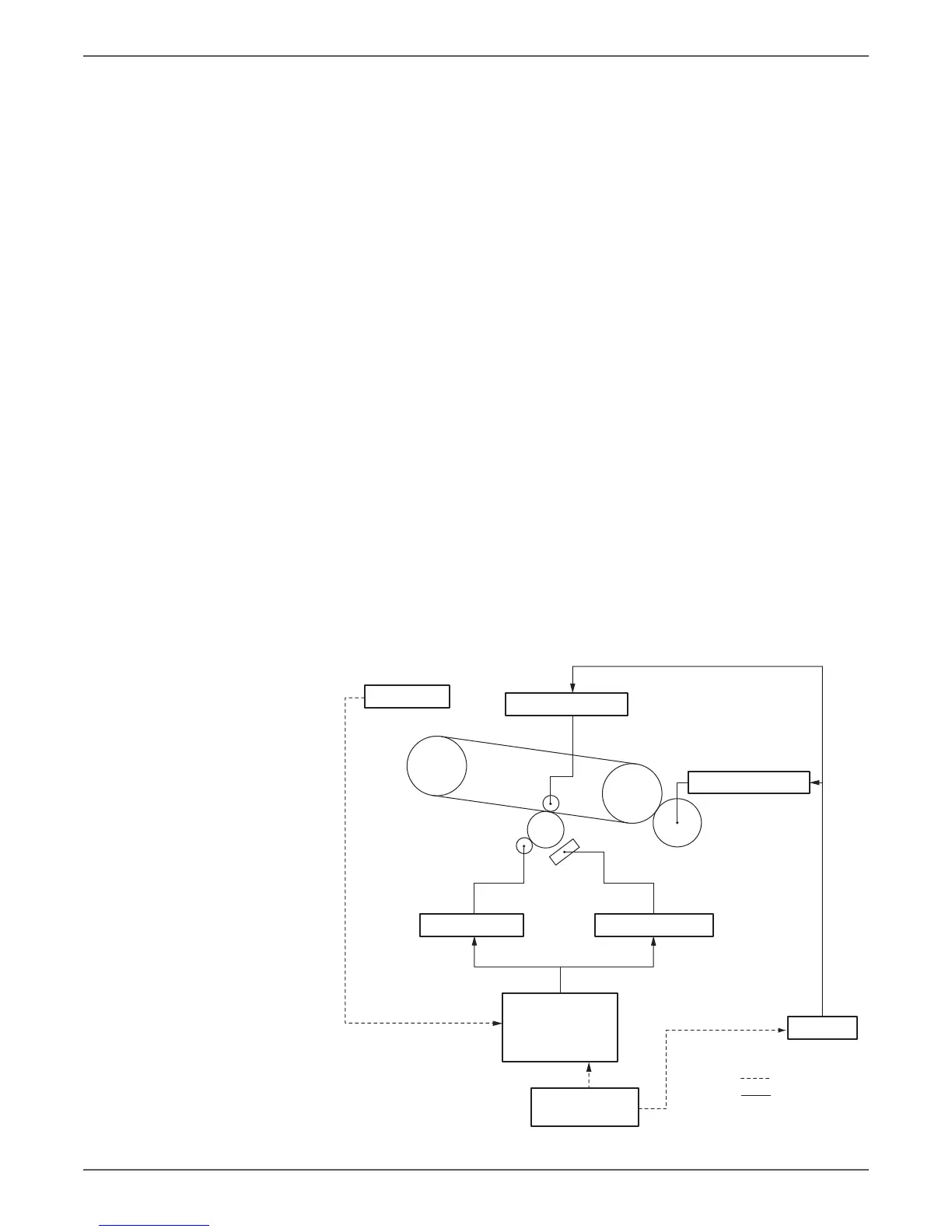

developing bias voltage is established that prevents leak image or uneven

density.

• IDC Sensor intensity control

Adjustments are made to correct changes in IDC Sensor characteristics due to

changes over time or contamination. The IDC Sensor is a photo-reflective

sensor that emits light from an LED and detects the reflected light returning

from the Transfer Belt. The light emitted from the LED is controlled so that the

reflected light density is constant.

• Reflectance measurement control

The reflectance of the Transfer Belt is measured using the IDC Sensor. The

measurement is taken for one complete revolution of the Transfer Belt. The

measured value is corrected during the intensity adjustment and G-correction

control.

• Toner adherence control

The developing bias voltage value is adjusted to keep constant the amount of

toner sticking to the surface of the Drum with reference to the 100% solid

image.

• Laser intensity adjustment control

Characteristics of the Drum, developing, and charging processes are affected

over time and by the environment. The intensity of the laser light is adjusted

so that fine lines and gradations of a predetermined level are reproduced at

all times.

• G-correction control

A gradation pattern is produced on the surface of the Transfer Belt. The IDC

Sensor measures the density of the pattern and sends the measured result to

the controller for gradation adjustment.

s6121mfp-147

IN

OUT

Grid Bias Developing Bias

Developing

Charging

PC

ADC Sensor

Temperature/

Humidity Sensor

ADC Control

1st Transfer Roller

2nd Transfer Roller

ATVC

Loading...

Loading...