Layout and function

30

GreenDrill BAH0054-9 11.17

4 Layout and function

The GreenDrill is used for spreading catch crops and re-seeding grass.

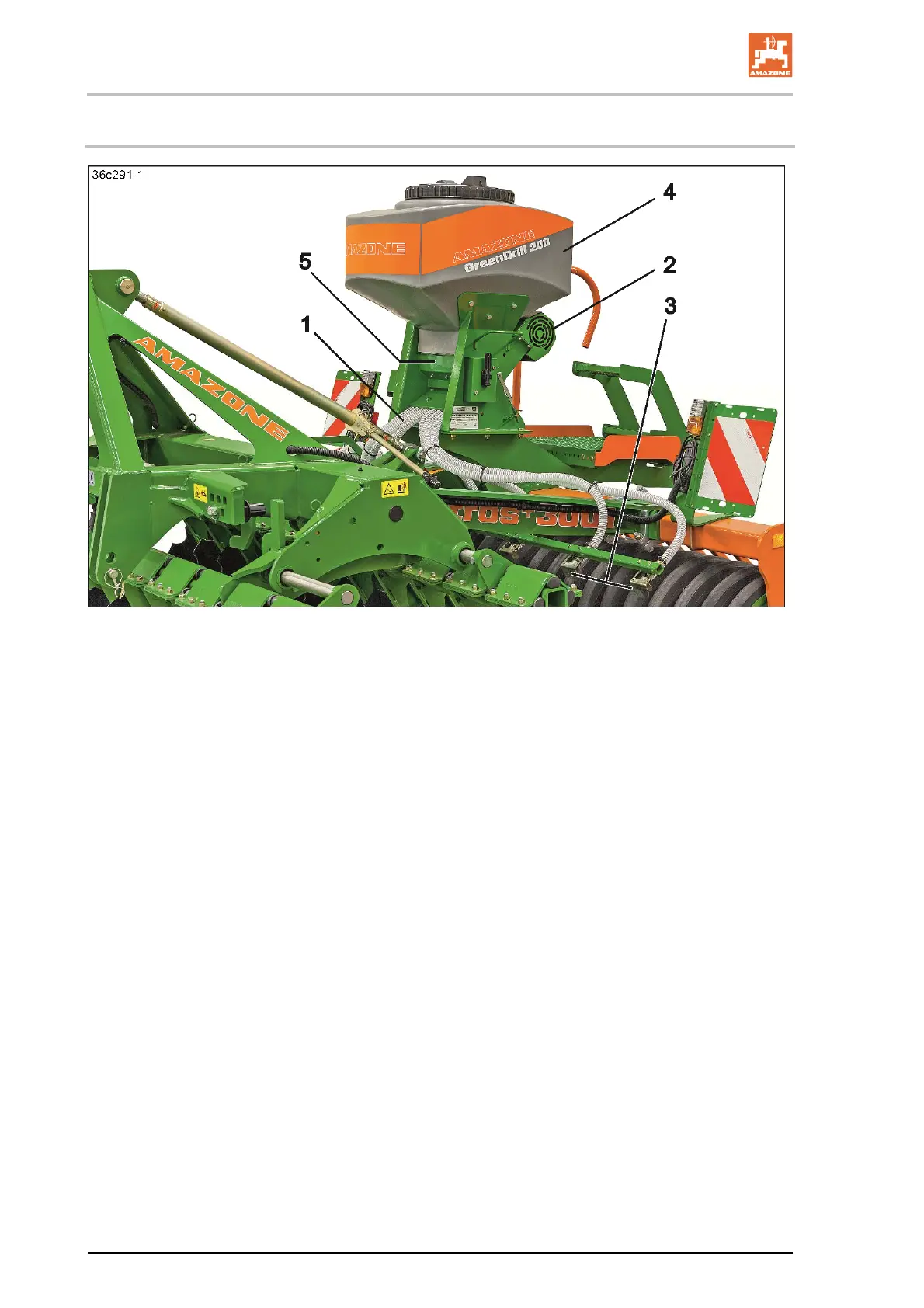

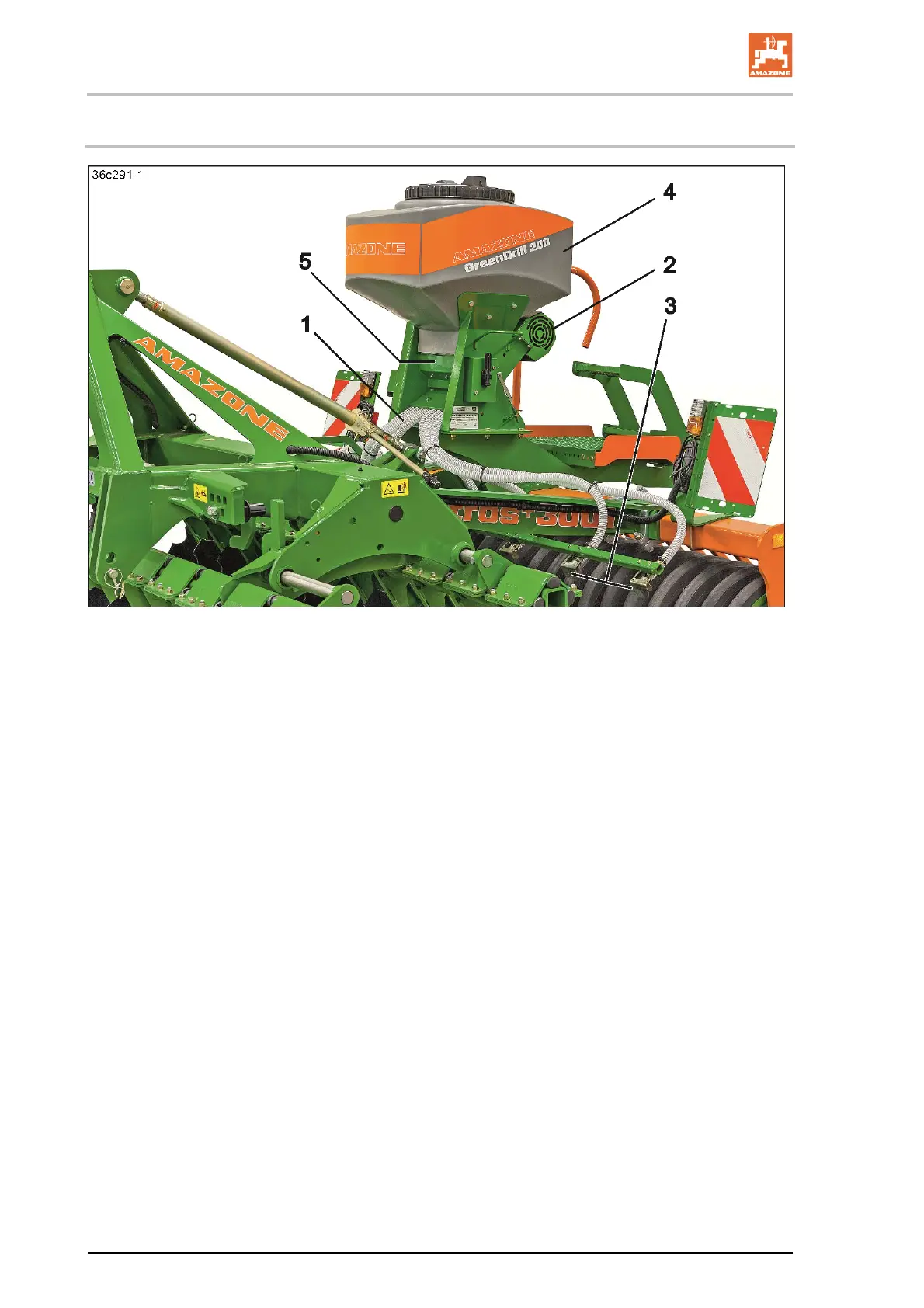

The seed metered by the seed metering wheels is conveyed into the seed hoses (1).

An electrically or hydraulically driven blower fan (2) produces the air flow to deliver the seed. The

GreenDrill GD500-D is fed by the blower fan of the carrying implement. The seed is spread using baf-

fle plates (3) in the operating area of the tillage implement tools working in the soil.

The seed hopper (4) has a volume of 200 or 500 litres, depending on the version. The seed hopper

and metering unit form a sealed pressurised system.

Dosing is carried out by a seeding shaft equipped with seed metering wheels, located in the dosing

housing (5). A 12 V electric drive motor drives the seeding shaft.

The GreenDrill control terminal is available in 2 versions and is operated from the driver's seat in the

tractor cab.

Control terminal 3.2

serves to switch the seeding shaft and the blower fan on and off. The speed of the seeding shaft can

be adjusted.

Control terminal 5.2

has a selection menu, e.g. for assisting with the calibration procedure.

The control terminal 5.2 must be connected to the 7-pin signal socket of the tractor or the radar or

GPS device to display the forward speed, the worked area and the working hours.

The control terminal then shows the forward speed [km/h] and adjusts the seeding shaft speed accord-

ing to the changing forward speed. The seed rate [kg/ha] remains unchanged even at varying forward

speeds. If it is set correctly, speed differences of 50 % are adjusted up and down. Even turning at the

end of the field is automatic.

Loading...

Loading...