6-38

129390199 Operator Manual Sterilizer Operation

6.16 Emergency

Manual Exhaust

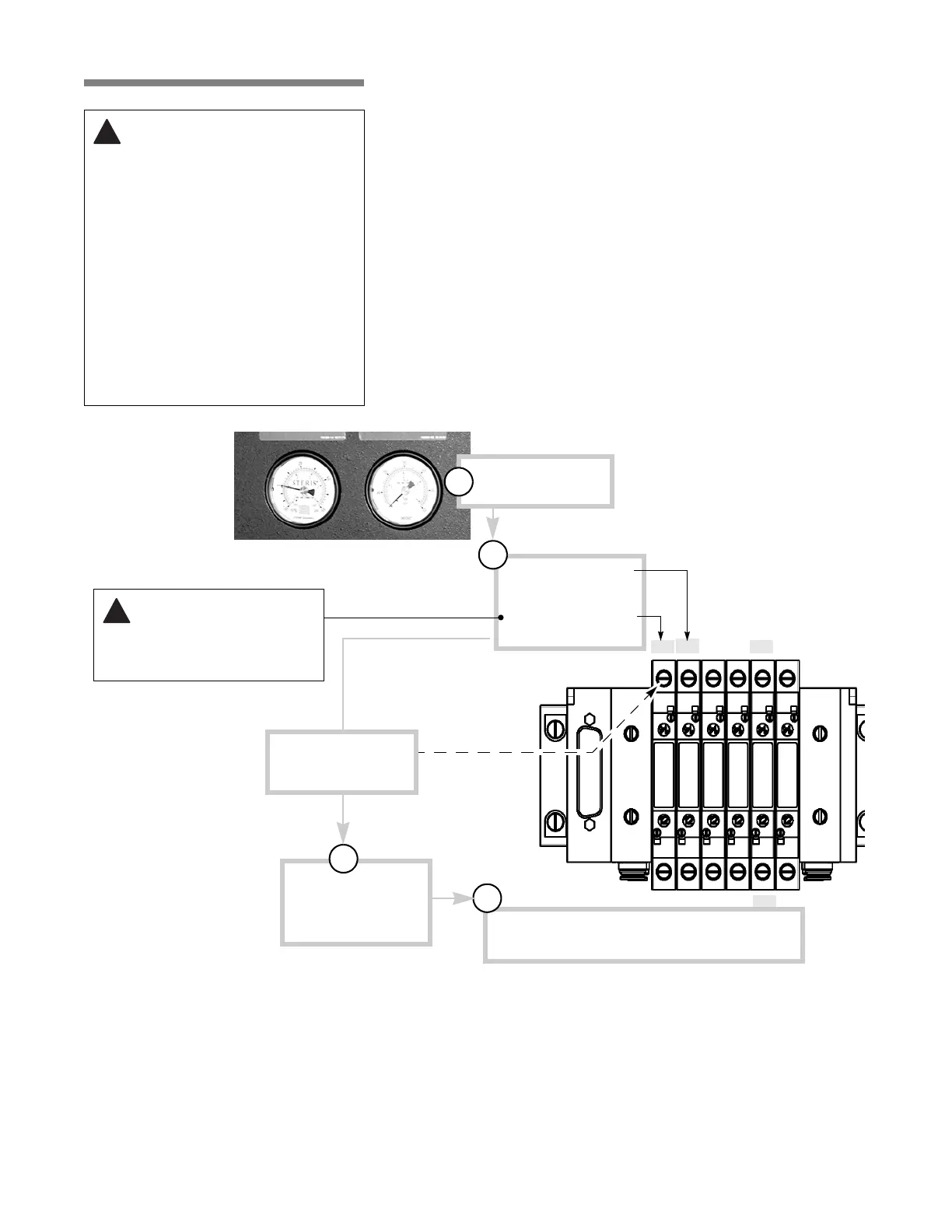

Important: Air pressure to the air manifold is required for this

procedure. Air manifold is located on top rail of plumbing stand (in

service area).

If a power failure should occur in the facility, or the sterilizer should

cease functioning, it may be necessary to manually exhaust the

sterilizer chamber. The sterilizer chamber should only be manually

exhausted if there is an immediate, critical need for load contents.

Tools Required: Small, flat blade screwdriver (1/8" [5 mm] tip).

NOTE: The emergency exhaust procedure is not feasible without

access to service area. Service area access is necessary to manually

activate air manifold switches.

1. Look at chamber and jacket pressure gauges on front panel of

sterilizer to determine if chamber is pressurized or is holding

vacuum.

2. If chamber gauge indicates pressure, activate switch V3 on air

manifold. If chamber gauge indicates vacuum, activate switch

V1 on air manifold.

WARNING – BURN HAZARD:

• Steam may be released from

the chamber when door is

opened. Step back from the

sterilizer each time the door is

opened to minimize contact

with steam vapor.

• Sterilizer, rack/shelves and

loading car will be hot after

cycle is run. Always wear

protective gloves and apron

when removing a processed

load. Protective gloves and

apron must be worn when

reloading sterilizer following

the previous operation.

Figure 6-16. Air Manifold

(Located on Top Rail of Plumbing Stand in Service Area)

V1

V3

V7

V35

V40

V2 V4 V9 V36 V46

Look for pressure or

vacuum in chamber

Activate

V1 to relieve

vacuum

Activate V3 to relieve

pressure

2

4

At 5 psig/inHg activate V37 for OE seal (and V38

for NOE, if necessary).

Gauges on sterilizer control panel

3

Wait for chamber to

reach atmospheric level

of 5 psig (or 5 inHg)

1

CAUTION – POSSIBLE

EQUIPMENT DAMAGE

HAZARD: Do not manually

activate V1 if the chamber

is holding pressure.

V38

V37

NOTE: Push in and turn

screw head to manually

activate valve

Loading...

Loading...