STwrench User Guide Troubleshooting guide

9836 4134 01 Edition 2.9 307 (326)

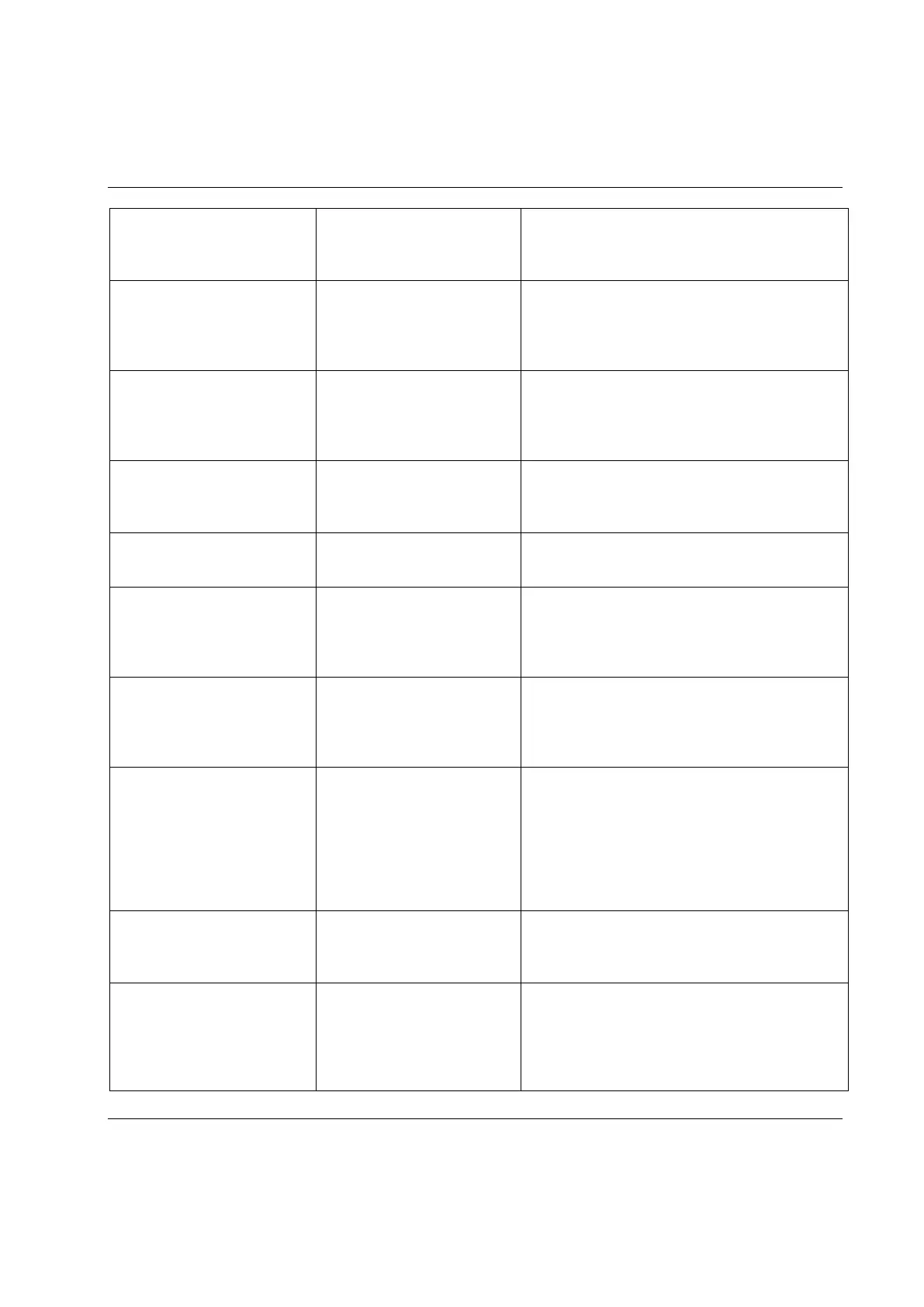

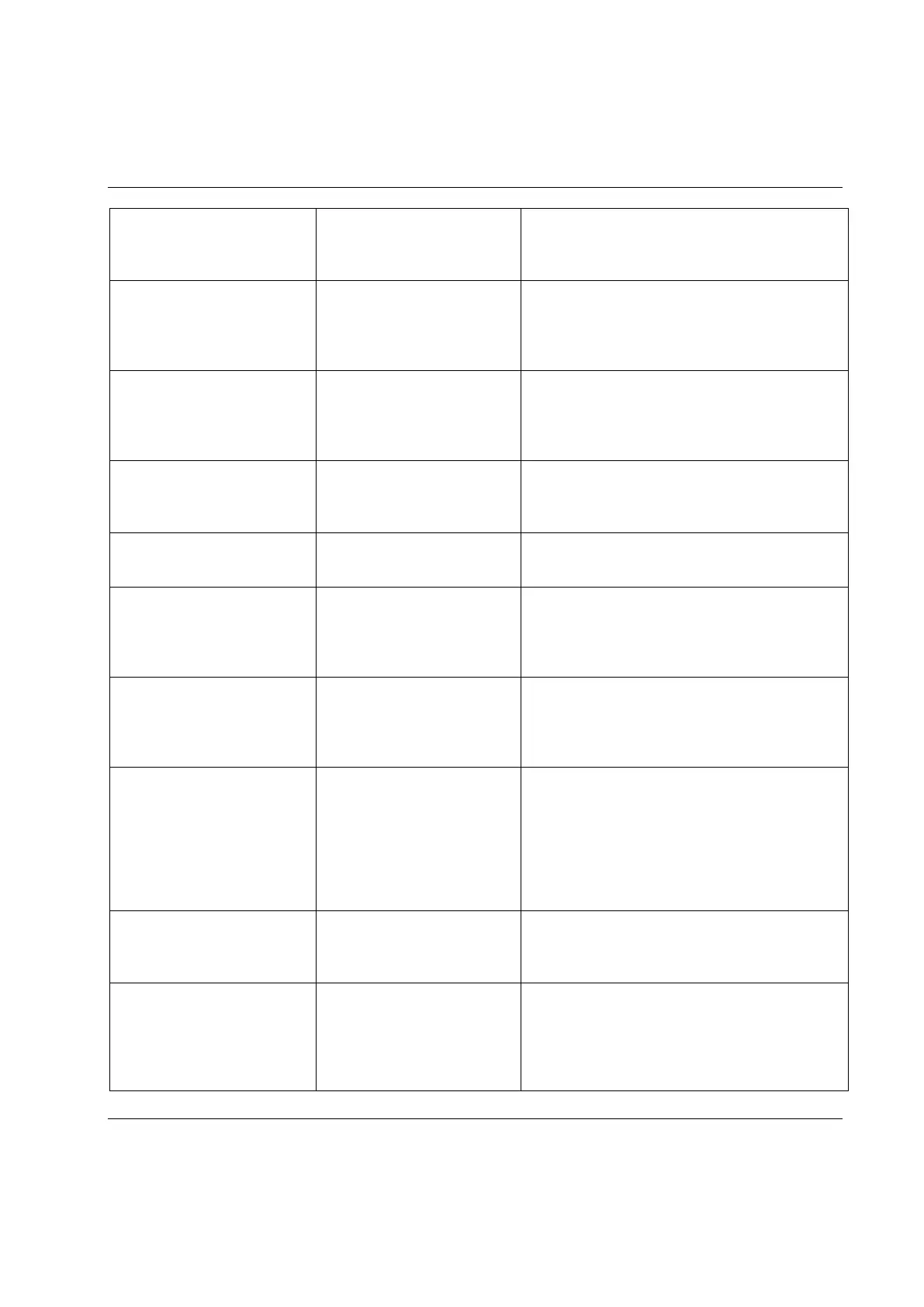

Prog. Missing is shown on

wrench display

contains a Pset which is not

defined in the Pset list

- Delete the missing Pset from the Multistage/Job,

or add the missing Pset to the Pset list

Radio not present is shown on

wrench display

- Radio module not present

but STwrench connected to

Power Focus via radio

module.

- Install the radio module in the STwrench, or

disable the Power Focus connection.

RBU incompatible is shown

on wrench display

- The new RBU installed in

the wrench is not compatible

with the data store in the

wrench memory

- Select RBU data and not wrench data in order to

work with the new RBU, or use a different RBU

supporting the data stored in the wrench memory.

RBU not Present is shown on

wrench display

properly installed in the

wrench controller

- Verify proper installation of RBU

STw Not Calibrated is shown

on wrench display

- smartHEAD not calibrated

- Calibrate smartHEAD or replace smartHEAD

with a calibrated one.

Transducer Blocked is shown

on wrench display

- smartHEAD not present in

the wrench, or data reading

not consistent

- Verify that smartHEAD is properly installed on

the wrench controller. Verify also that the

contacts of the smartHEAD and controller are

clean and not damaged.

Transducer overloaded, or

Transducer overloaded please

return it to customer center is

shown on wrench display

overloaded (more than 120%

of its capacity).

- The smartHEAD must be sent to our customer

centre for inspection. Recalibration is then

required to restore normal operation.

Wrench not reading torque

and/or angle values in Prog.

Mode, but reading correct

values in free mode

- Incorrect torque and/or

angle correction coefficient

settings in the RFID TAG of

the end-fitting tool

- By using the TAG WRITER function, verify the

torque and angle correction coefficients. If no

extension is used, the Torque coefficient must be

set to 1, and the Angle coefficient must be set to

0.

If a wrench extension is used, perform the CCA

procedure to calculate the 2 coefficients.

Shock indicator colored in red

- STwrench exposed to shock

over the limit

- Complete check of wrench functionality and

recalibration, after which the shock indicator has

to be replaced.

installation

- Wrong wrench settings

- Verify proper module installation.

- Verify that barcode is activated in the tightening

programs,

and the identifier section of the

ToolsTalk BLM is configured properly.

Loading...

Loading...