Step 5:

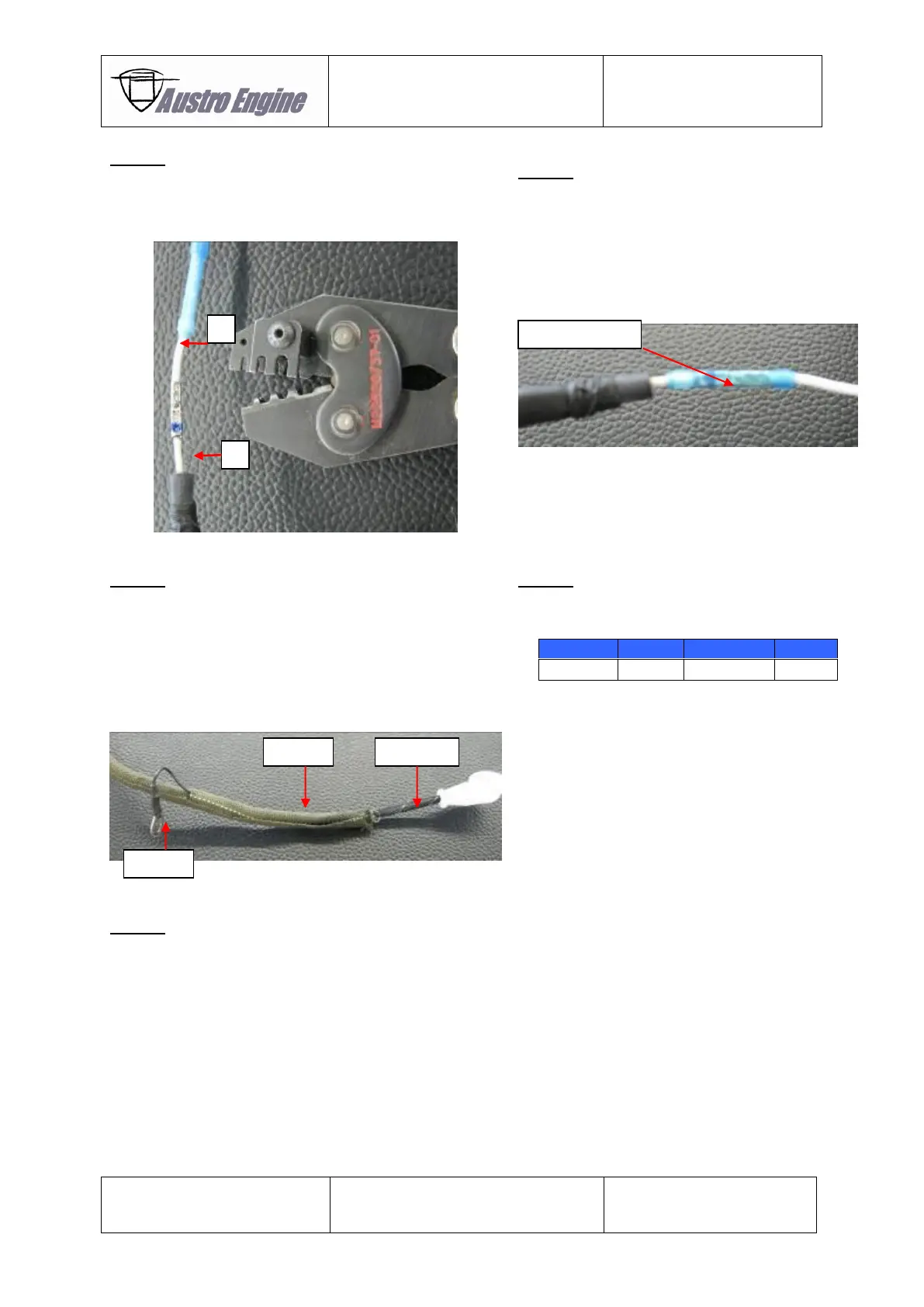

Use the crimp tool Mil Standard Part Number:

M22520/37-01 to connect the repair kit cable (A) and

the remaining engine harness (B).

Step 6:

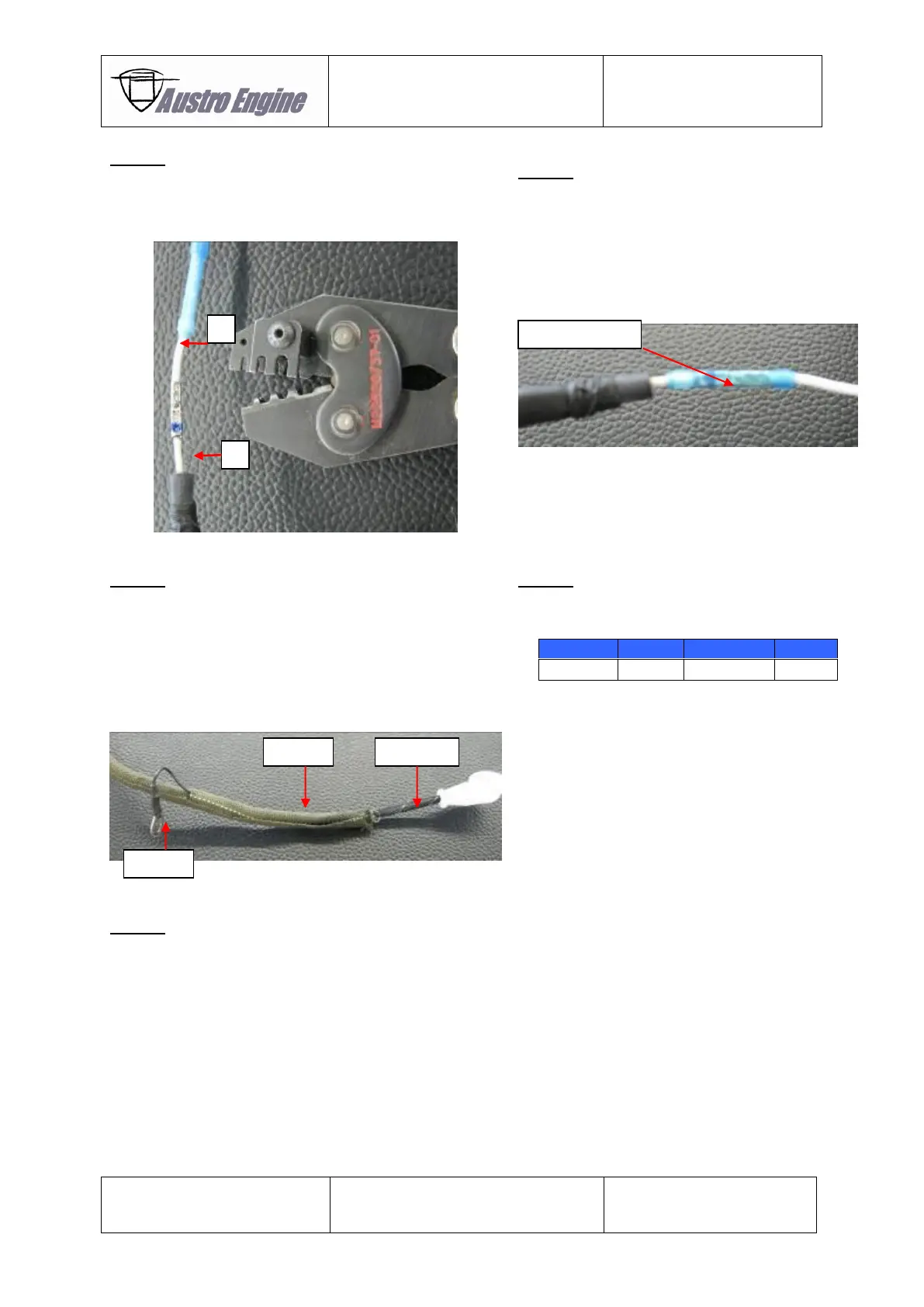

Put the blue isolation sleeve of the inline crimp

D-436-37 directly over the splice crimp.

Heat the inline crimp isolation sleeve (300°C –

350°C) with a “hot air gun” until the inline crimp

isolation seals the inline crimp barrel and the

single wires.

If necessary the green roundit 2000NX5-5 which is part

of the repair kit can be put over inline crimp and the

black expando of the repair kit cable.

If the green roundit of the remaining harness is long

enough to cover the inline crimp and the black expando

this step will not be needed.

Ensure that the pig tail is not covered by the roundit.

Use a Multimeter to check connection between

the pins stated below:

Cable ties PLT1M-M30 and PLT4S-M30 can be used for

fixation of repair kit cable.

Loading...

Loading...