R5906848 /04 DP2K SLP Series140

11.1 Introduction of the Integration Rod

Functionality of the Integration Rod

The Integration Rod is made of fused silica and is approximately 14 centimeter long. The cross-section of the

rod has the same aspect ratio as the active surface of the DMD's used in the Light Processor. The function of

the Integration Rod is to match the shape of the light path to the shape of the DMD's and to neutralize the hot

spot effect caused by the light source.

The Integration Rod is located at the entrance of the Light Pipe. The light emitted by the light source is

reflected via the Cold Mirror into the rod, which integrates the incoming light into a homogeneous rectangle

shaped beam of light.

Image 11-1

The entrance and exit side of the Integration Rod are coated to achieve optimal performance. Clearly the rod

may never be contaminated with grease, dirt, liquid or the such. For optimal protection the rod is mounted on

an aluminium rod holder, which requires replacing together with the rod. The Integration Rod and the

aluminium rod holder together form the “Integration Rod assembly”.

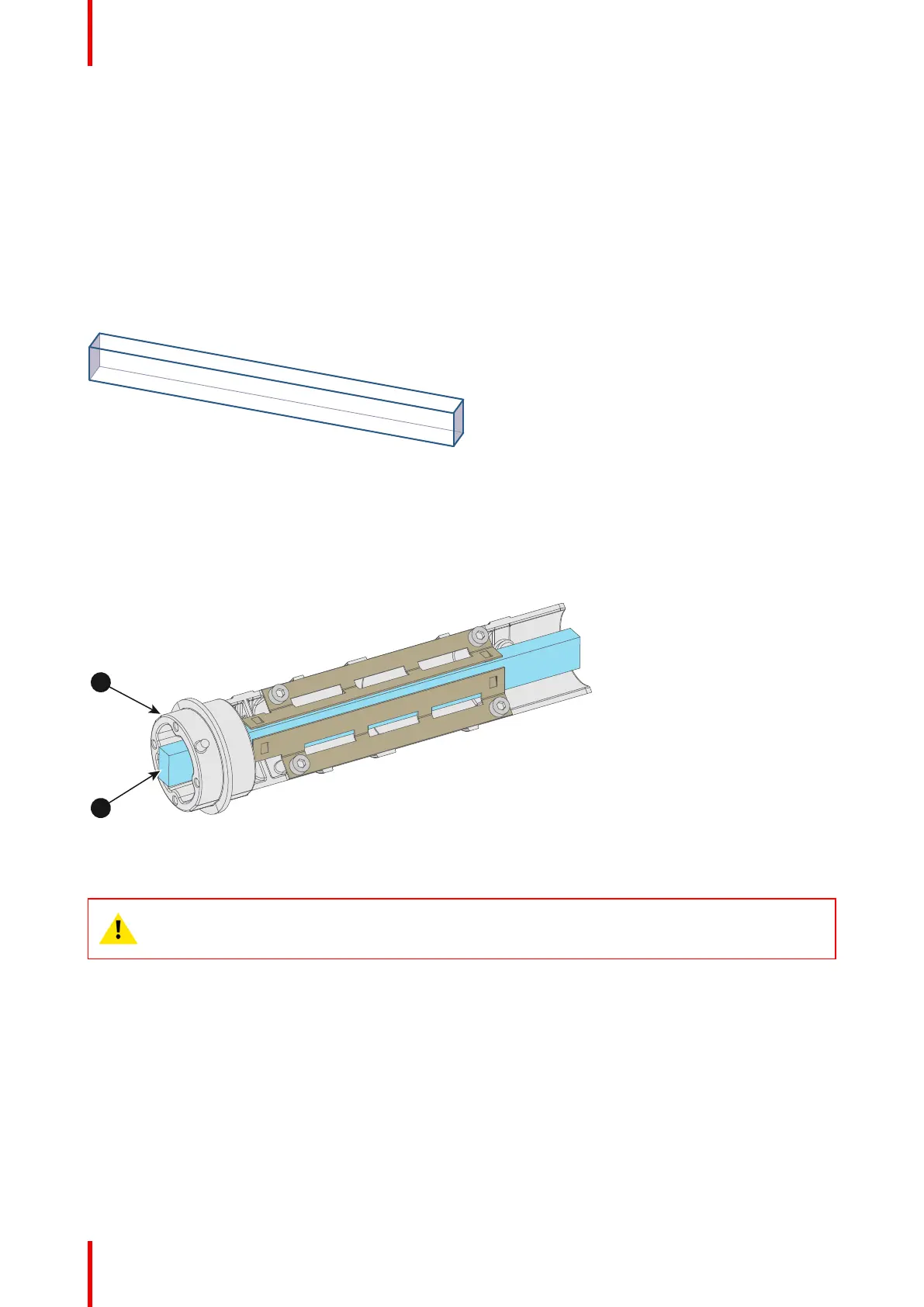

Parts Integration Rod assembly

Image 11-2

1 Integration Rod housing.

2 Integration Rod (entrance side).

CAUTION: Never touch the entrance or exit of the Integration Rod assembly. Greasy fingerprints or

other dirt on the Integration Rod entrance or exit will burn into the rod and cause permanent

damage.

11.2 Integration Rod diagnostic

General

Due to bad environmental conditions the Integration Rod may become contaminated with grease, dust, dirt or

other particles, which will burn into the rod and cause permanent damage. As a result spots may become

visible in the projected image on the screen. To confirm that these spots are caused by a damages to the rod

please diagnose the rod as described in the following procedure.

Required tools

• 7mm flat screw driver.

Integration Rod

Loading...

Loading...