153

THIS IS AN UNCONTROLLED DOCUMENT.

THIS ELECTRONIC DOCUMENT MAY HAVE BEEN SUPERCEDED.

THE MOST CURRENT DOCUMENT INFORMATION IS AVAILABLE

FROM YOUR BELL HELICOPTER TEXTRON REPRESENTATIVE.

PRODUCT DATA JANUARY 2003

CONSTRUCTION FEATURES

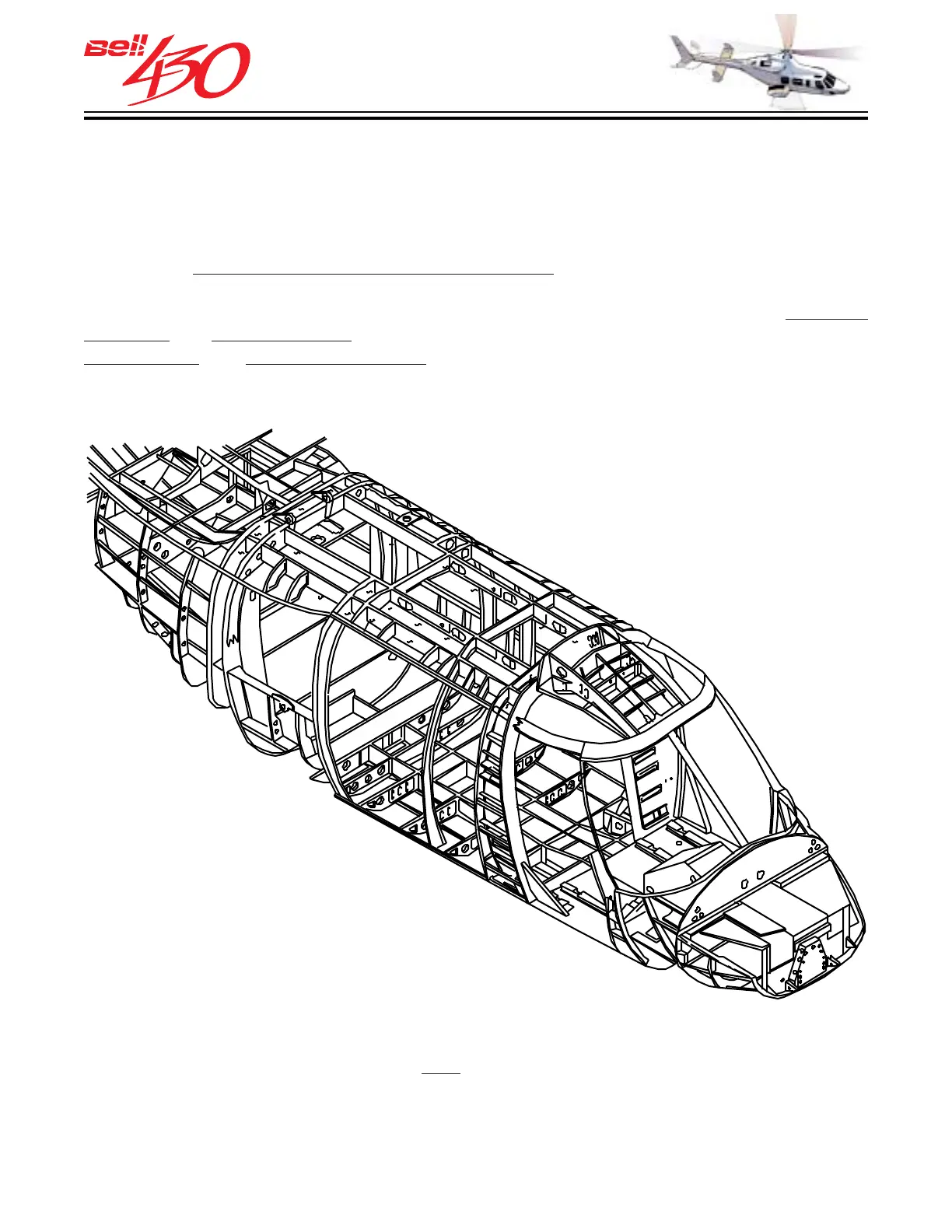

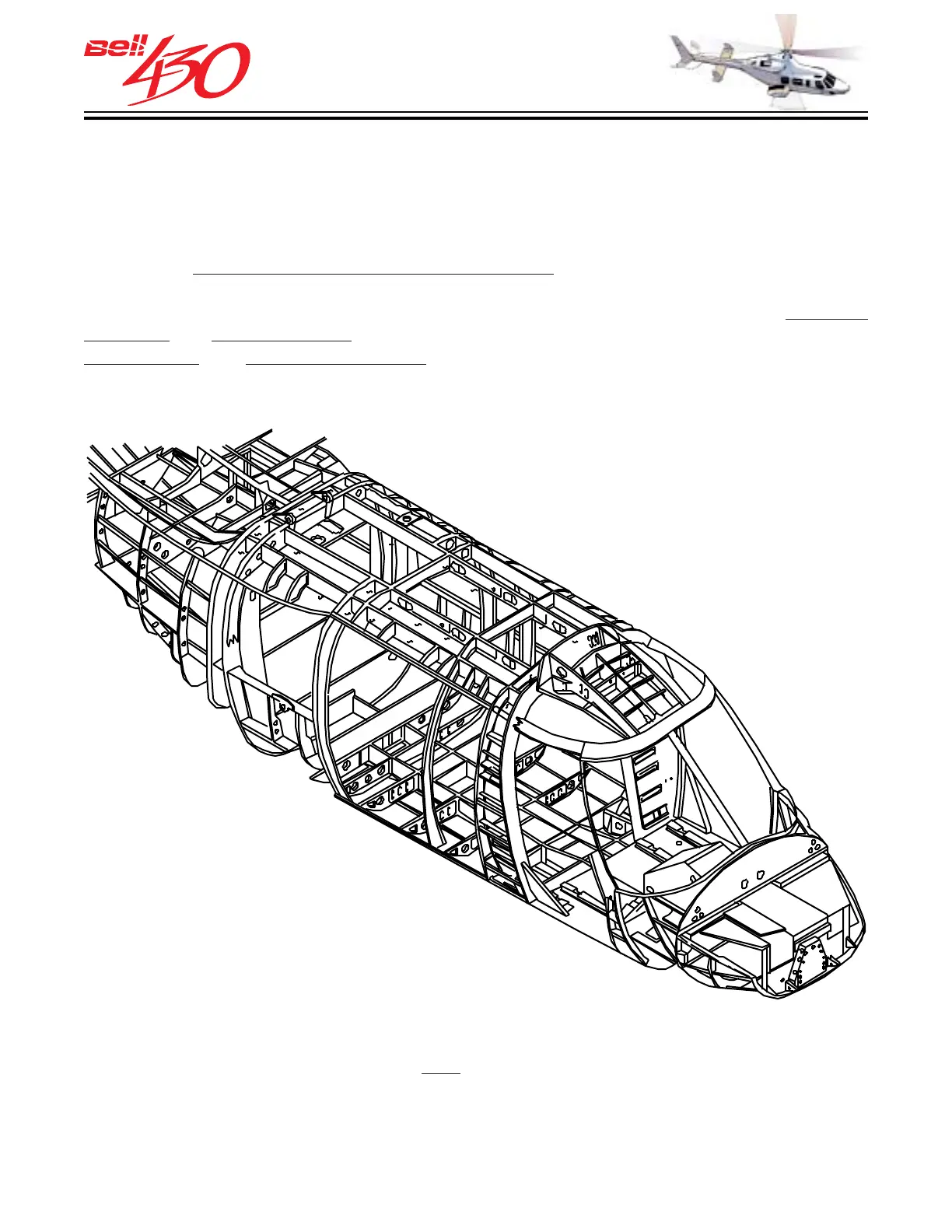

The airframe is a conventional semi-monocoque structure of bulkheads, support beams,

stringers, and cast and machined fittings, which are held together by intercostals and

covered with an external skin. The primary construction material is corrosion resistant

aluminum alloy. It features extensive use of high temperature bonded honeycomb

panels with

long life, high strength, and light weight. Non-structural fiberglass molded

panels are also used. These reduce maintenance requirements and enhance the overall

appearance of the helicopter by presenting smooth contours. Protection against

corrosive

elements and galvanic action is provided by a coating of epoxy polyamide primer. All

panel edges and fiberglass surfaces are sealed and spot welding is NOT used. The

exterior surface of the helicopter is further protected by very durable polyurethane

paint.

FUSELAGE ASSEMBLY

The fuselage assembly consists of three major components; the forward fuselage,

the aft fuselage, and the tail boom. The three sections of the fuselage assembly are

fixture (JIG) mated into one integral

unit. A tunnel extends along the centerline of the

fuselage to house and protect the electrical wiring that goes aft, and the flight control

mechanical linkage and hydraulic lines which operates the tail rotor. This permits ready

access without disturbing any of the interior.

Loading...

Loading...