152

Service Mode / Manual override

The activation of the manual override or errors when using the manual override are signaled by device

status LED / Top LED in the fault colour - see chapter “21.2Flashingpattern&faultsignalling”onpage143

or “Table15”onpage146

Procedure for activating & deactivating the manual override for valve location 2/A1:

→ Observe safety guidelines for the system prior to using the manual override!

→ Activatingthemagneticmanualoverride(onlypossibleinAutomaticmode):

Holdthemagneticmanualoverridetoolontheidenticationpointsbetweenthecableglandsforthree

seconds(see“Fig.49”),feedbackforactivationbydevicestatusLED/TopLED(“Table15”)

→ Once the measure has been completed, deactivate the magnetic manual override:

Holdthemanualoverridetoolontheidenticationpointsbetweenthecableglandsforanotherthree

seconds(see“Fig.49”).

After a power failure, the magnetic manual override is reset and the control head restarts in normal

operating mode, i.e. the signal from the higher-level control is accepted.

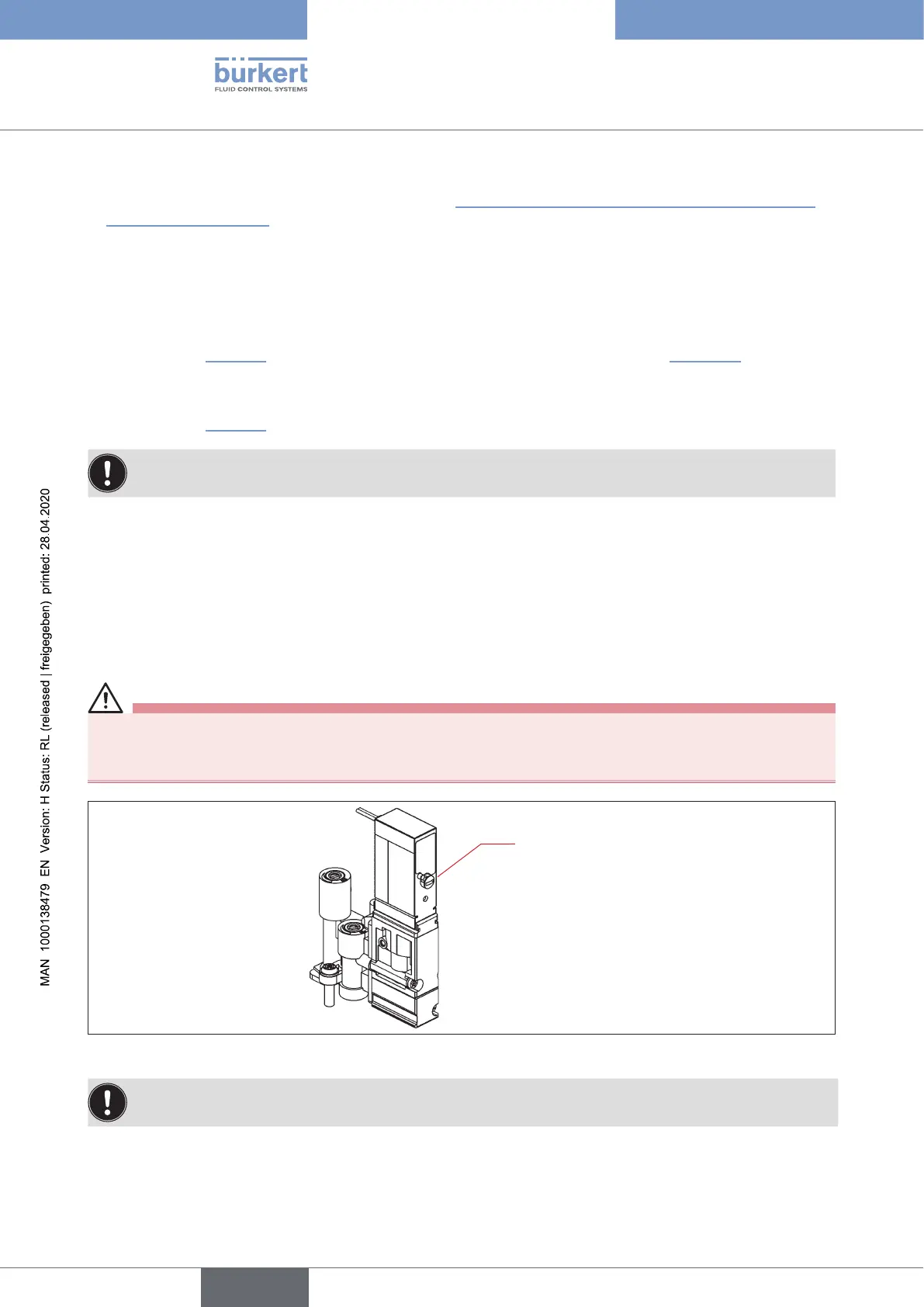

22.2 Mechanical manual override

Ifadditionalmanualoverridesarerequiredforadditionalservicepurposesorintheeventofafailureofthe

electrical energy, it is possible for all voltage and communication designs to switch the connected process

valve using the mechanical manual override of the respective solenoid valves V1 to V3 after opening the

housing.

DANGER!

Danger of explosion in a potentially explosive atmosphere (only in the event of a fault as zone 2)!

` Opening the hood or the housing in a potentially explosive atmosphere is only allowed in a not ener-

gised state!

red hand lever of the

mechanical manual

override:

Hand lever position:

left: 0

right: 1

Fig. 50: Mechanical manual override of the solenoid valves

When the service measures have been completed, reset all manual overrides to "0" for controlled

operation of the system!

english

Control Head Type 8681

Loading...

Loading...