33

Assembly

7.2.2 Assembly sequence on the example of a double-seated valve

Procedure:

→ Mount the piston rod with the target on the process valve spindle. Observe reference dimensions!

→ Fastenthehubangeontheprocessvalve-see“Fig.10”.

During this, observe central alignment and sealing conditions!

→ Checkthesecuretofthesealingrings(intheupperandlowergrooves).

→ Mountthecontrolheadonthehubange(seamlessly360°rotatable).

→ Securecontrolheadwiththetwolockingscrews(shoulderscrewsM5)inthemiddlegrooveofthehub

angetopreventitfrombeingpulledothehubange–tighteningtorque:max.3.2Nm(see“Fig.10”

and “7.2.3Realignmentofthecontrolhead”).

7.2.3 Realignment of the control head

Ifnecessary,thecontrolheadcanberealigned(rotated),inparticularifproperlyaccessibleinstallationof

thepneumaticsupplylinesisnotpossibleduetospatialconditions.Thismightalsoberequiredforopera-

tionalaspects(accessibilityofthemanualoverride)andbecauseofelectricalconnectionpossibilities.

Procedure:

→ Loosenthelockingscrews(shoulderscrewsM5–see“Fig.10”)slightlyuntiltheundersideofthescrew

headisushwiththeauxiliarysurfaceofthehousing.

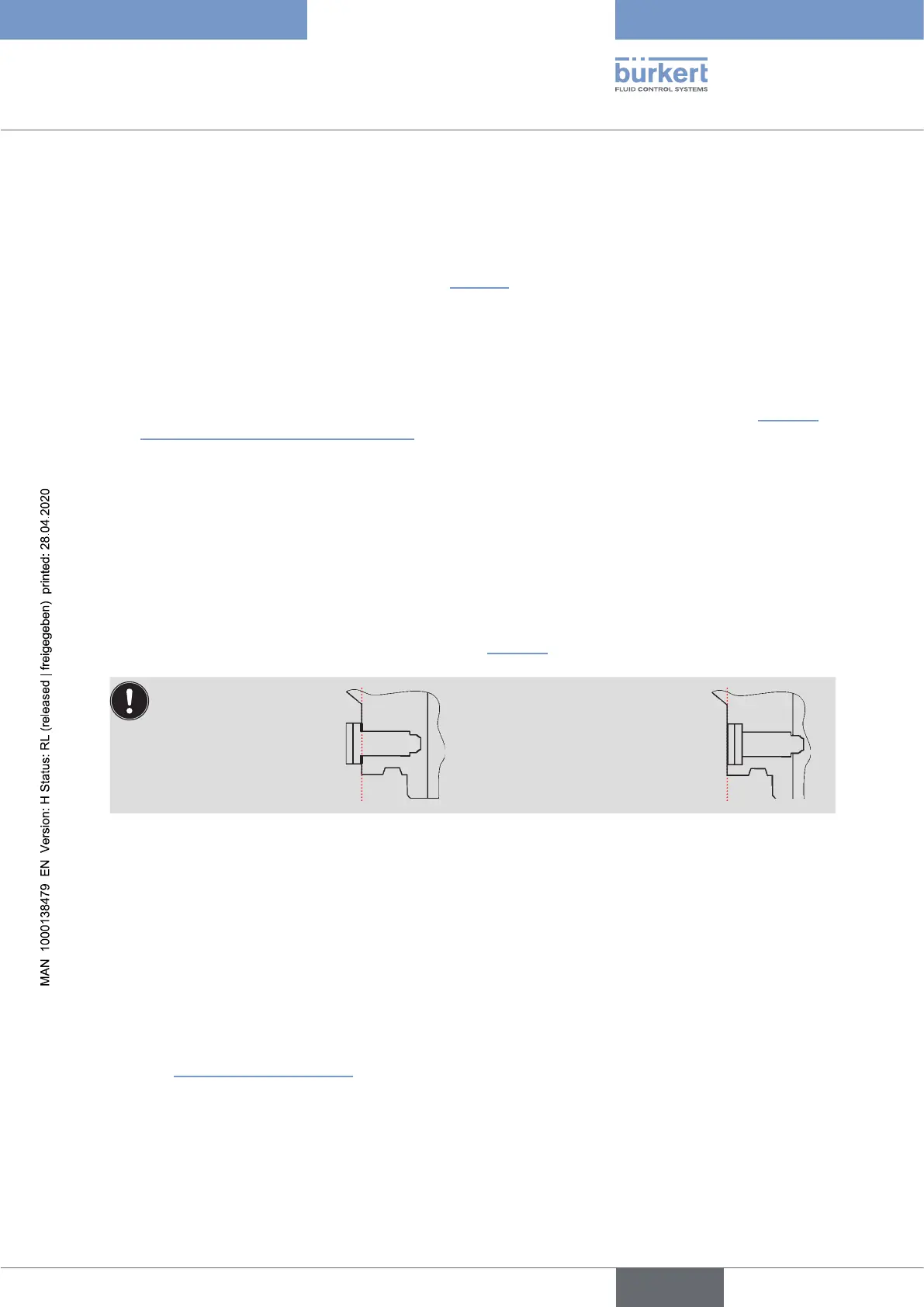

The locking screw has

beenloosenedsu-

ciently when the lower

side of the screw head

isushwiththeauxiliary

surface of the housing.

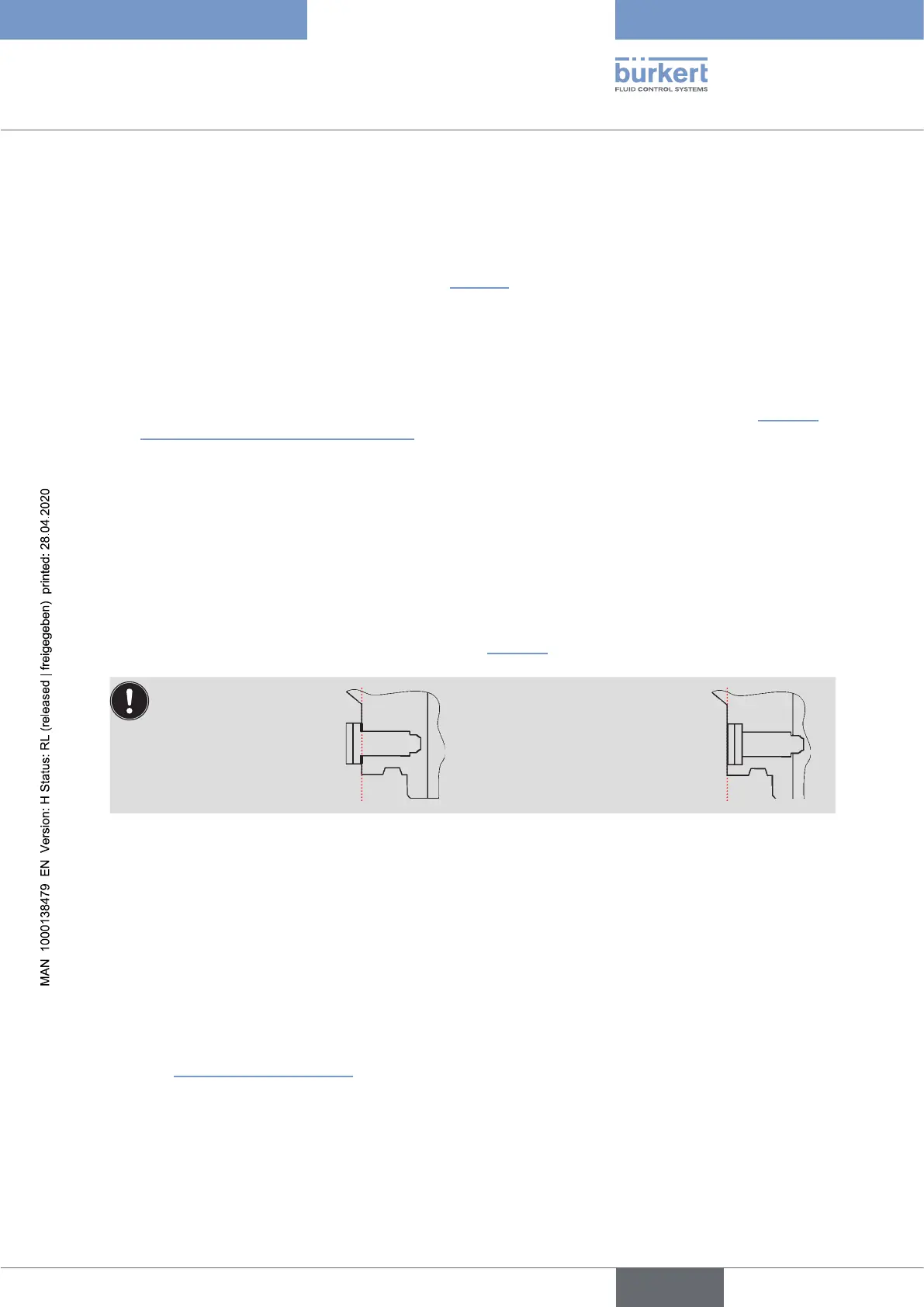

Thelockingscrewissuciently

tightened when the upper side of

thescrewheadisushwiththe

auxiliary surface of the housing.

Tightening torque: max. 3.2 Nm

→ Rotate the control head until the desired alignment has been achieved.

→ Securethecontrolheadwithlockingscrewsagainuntiltheuppersideofthescrewheadisushwith

the auxiliary surface of the housing. The locking screws have no sealing function. The control head is not

xedinplacebythelockingscrewsbutismerelysecuredagainstbeingpulledothehubange.

7.2.4 Assembly of the pneumatic and electrical connections

Pneumatic installation

see chapter

“9PneumaticInstallation”

english

Control Head Type 8681

Loading...

Loading...